Reversal stubble burying rotary cultivator

A technology of rotary tiller and rotary tiller, which is applied in the direction of tillage implements, agricultural machinery and implements, shovels, etc. It can solve the problems of high power consumption of the unit, increased power consumption, and poor surface flatness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

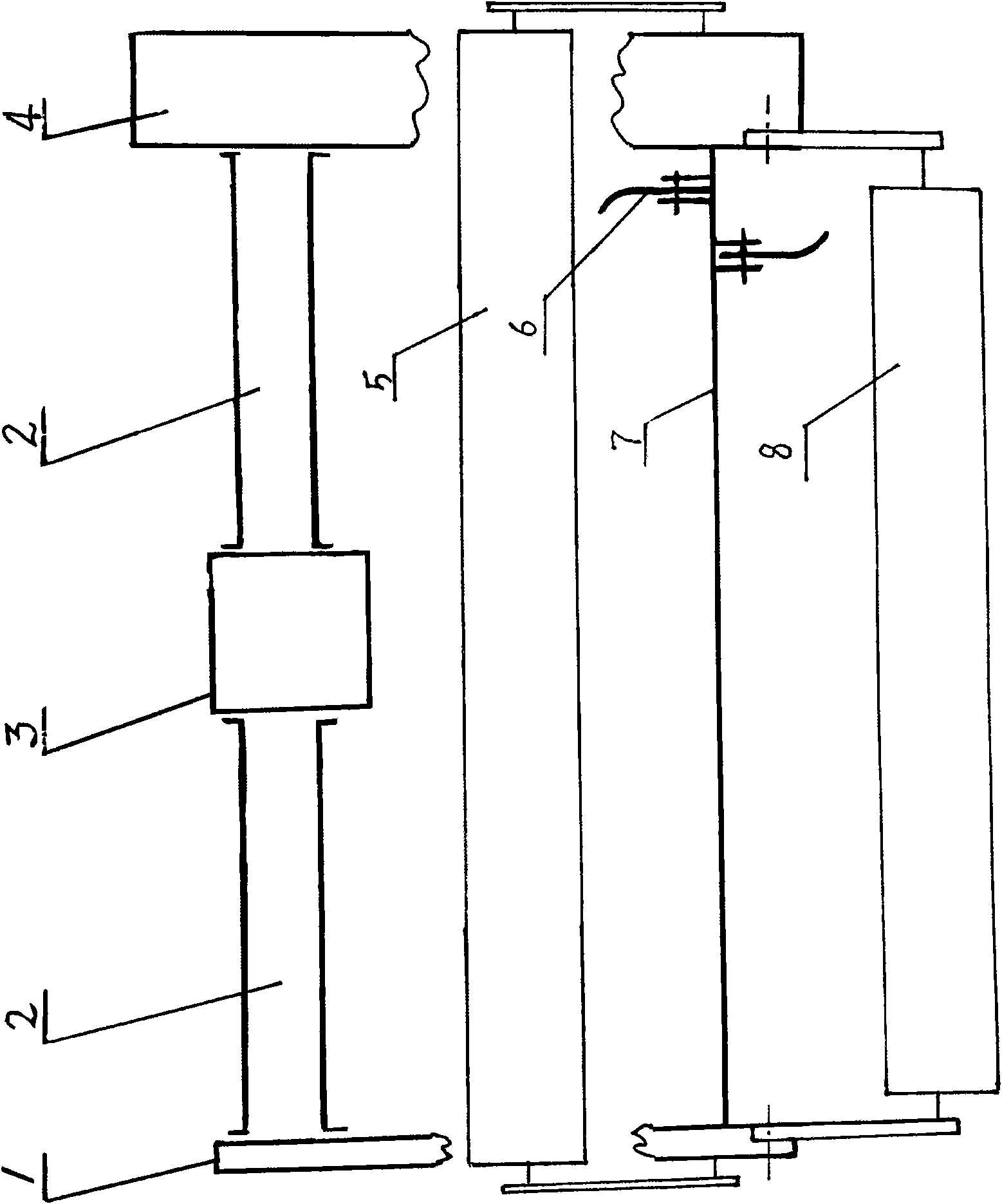

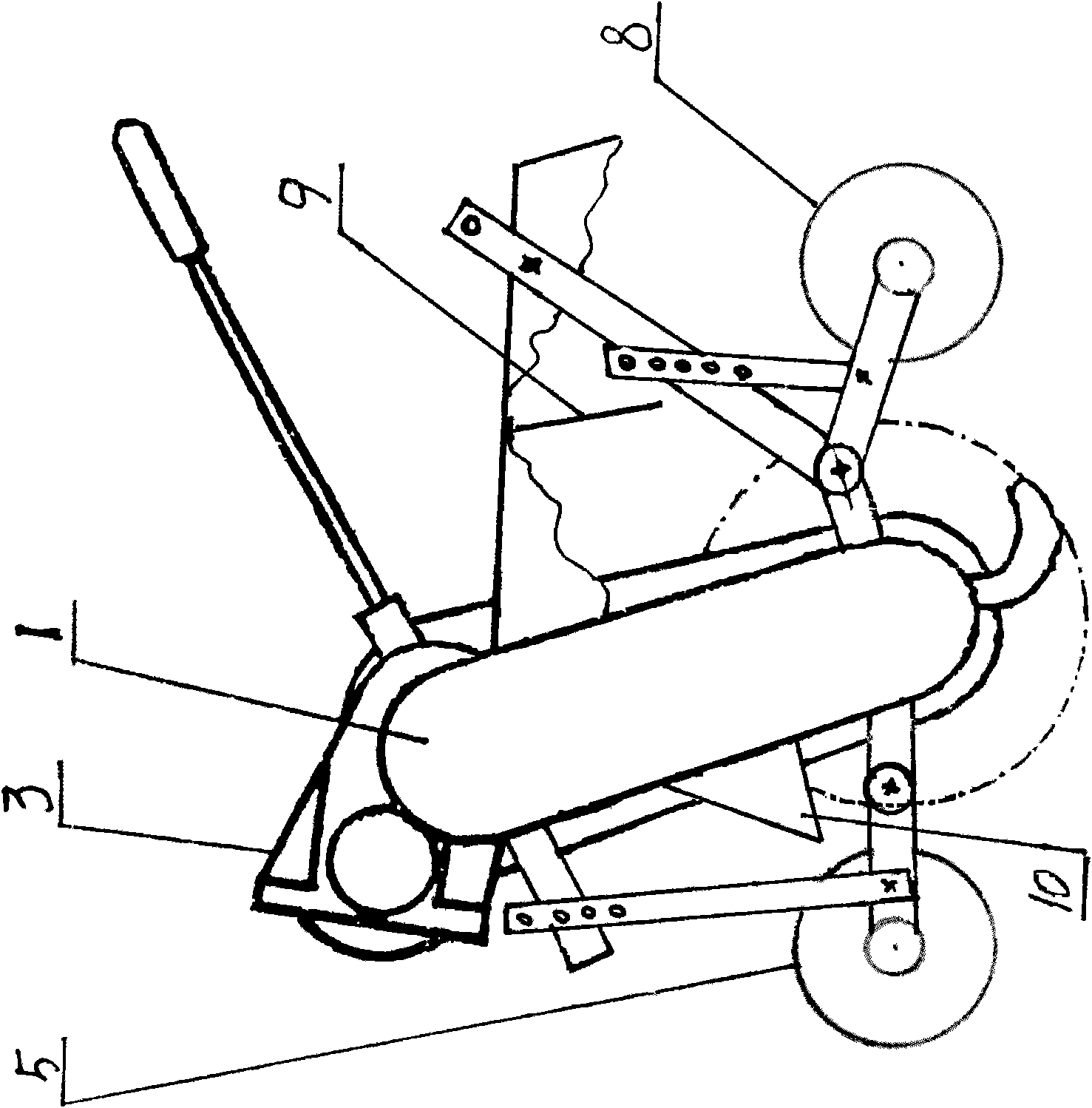

[0010] Such as figure 1 , figure 2 The shown reverse stubble burying rotary tiller comprises a gear box 3 fixed on the housing 2, a power transmission box 4 and a support arm 1, and the bottom of the power transmission box 4 and the support arm 1 supports the two ends of the rotary blade shaft 7. At the end, a pressure roller 5 is arranged directly in front of the rotary blade shaft 7, and a pressure roller 8 is arranged directly behind the rotary blade shaft 7. When the rotary blade shaft 7 reversely rotates and cuts the soil, the blocking The pressure roller 5 blocks the rotary-cut loose soil in front of the rotary tiller shaft 7 and does not turn forward, and the rapidly rotating rotary tiller 6 directs the rotary-cut loose soil and straw directly under the action of the front fender 10 . Throwing to the rear, the stalks are blocked by the fence 9 and fall in front of the fence 9. The center distance between the pressing roller 8 and the rotary tiller shaft 7 is 330-390 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com