Punch forming device of guide grooves of energy-absorbing box of automobile anti-collision rod

An automobile anti-collision bar, stamping and forming technology, applied in the field of metal stamping, can solve the problems of increasing processing cost, reducing processing efficiency, scratches, etc., and achieving the effects of high strength and reliability, reducing production cost and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

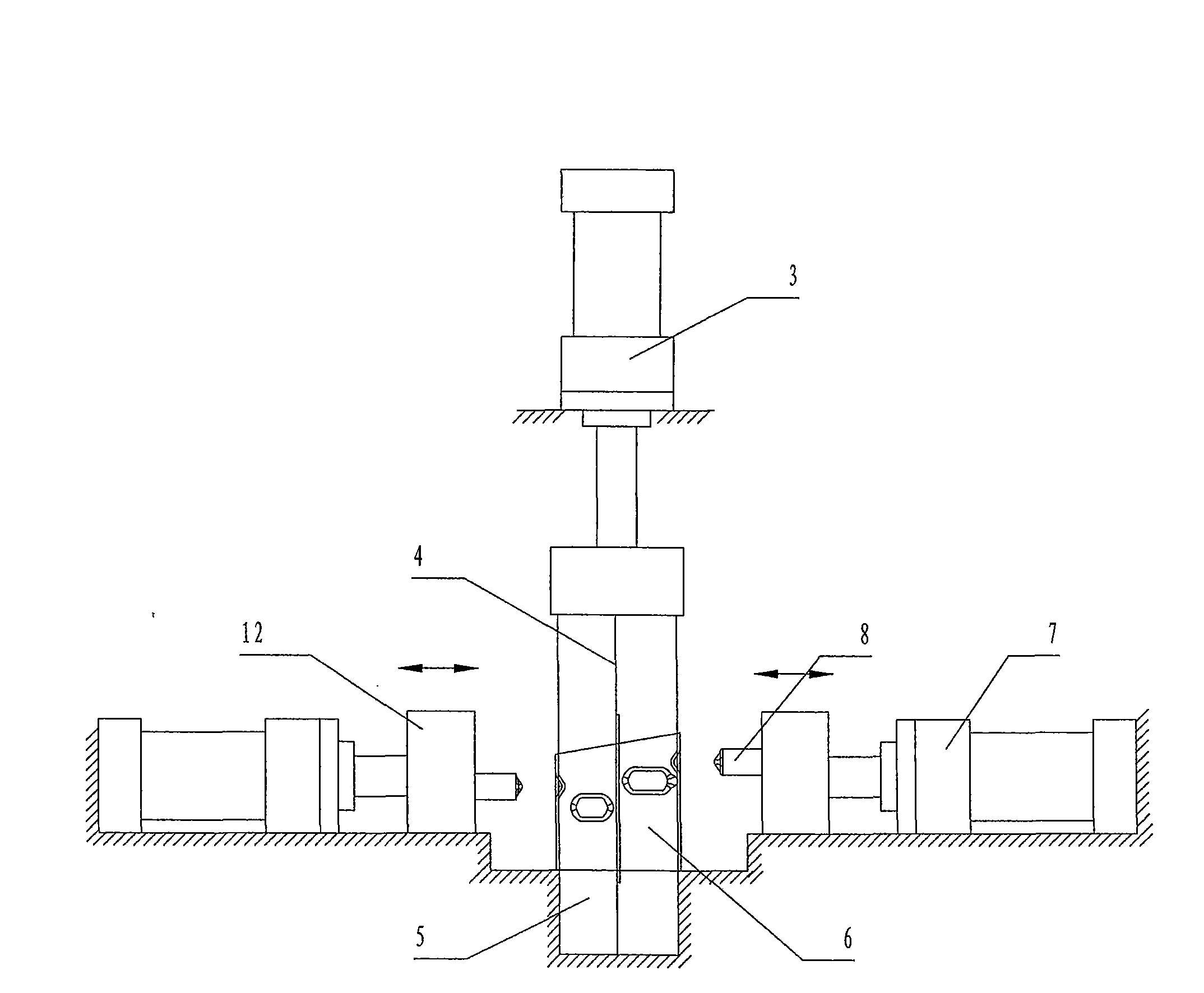

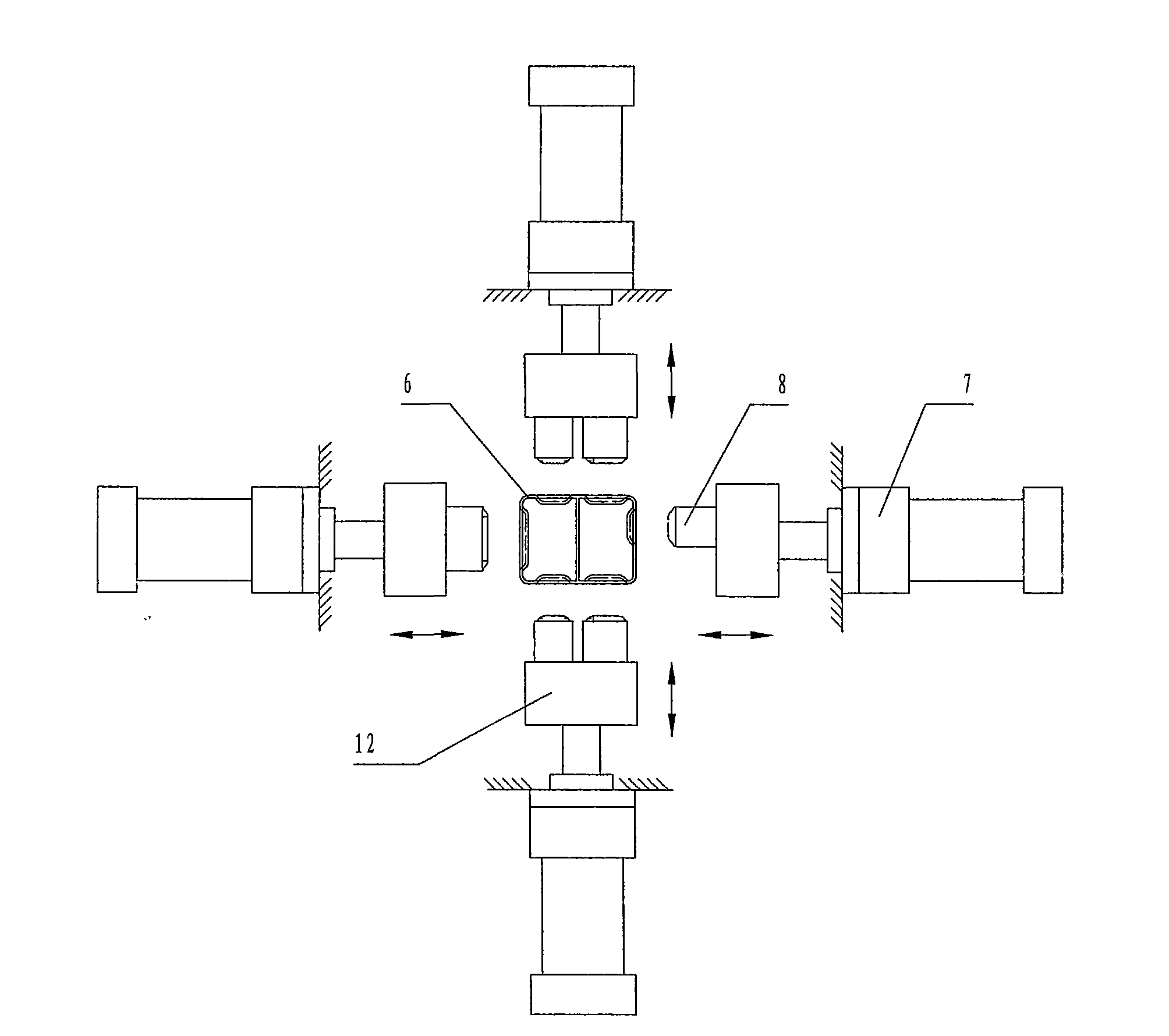

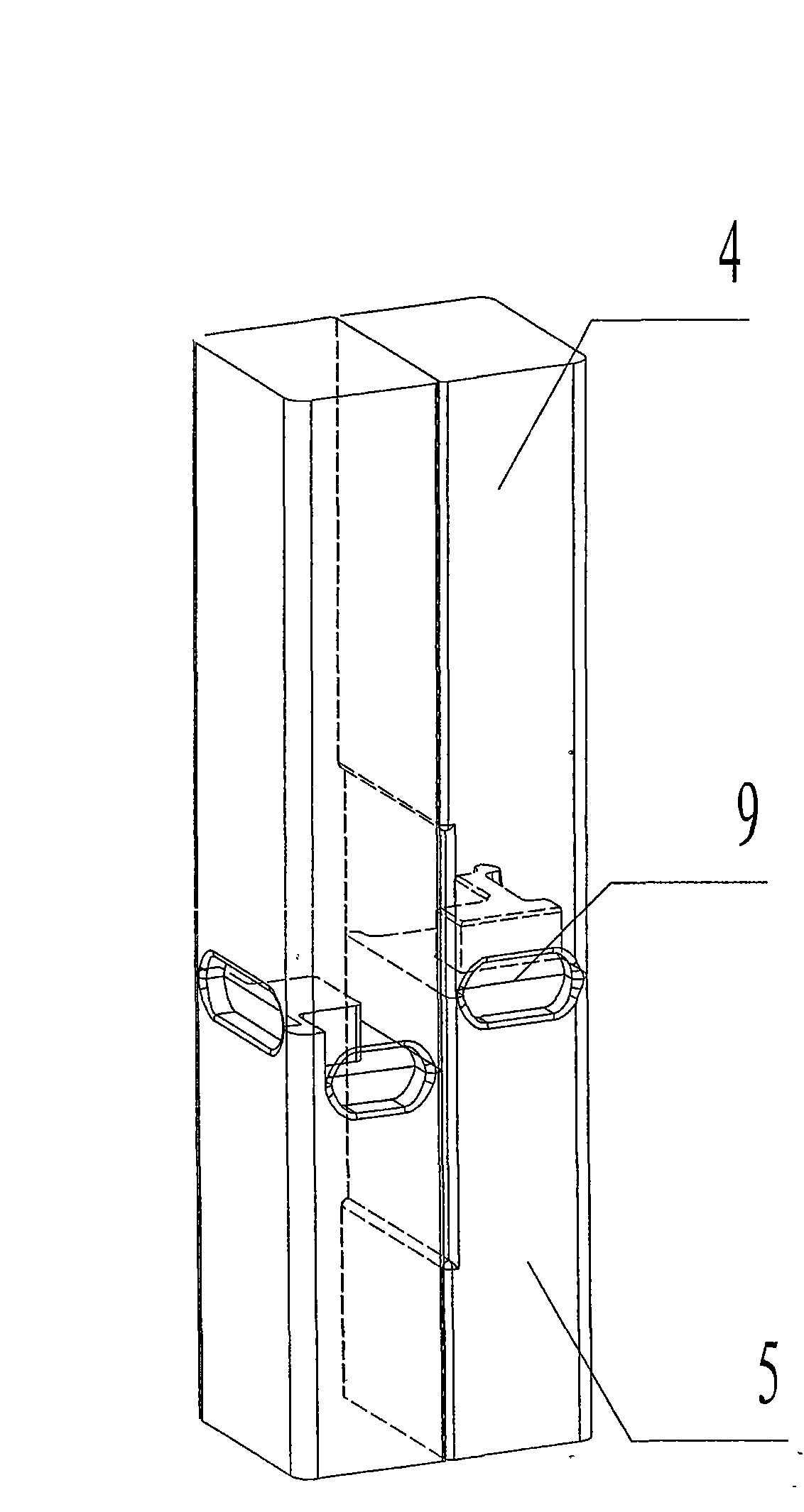

[0018] see Figure 1 ~ Figure 2 , the device includes a mandrel, a mandrel cylinder 3 and a stamping cylinder 7, and the mandrel with a split structure provides the possibility for one-time molding of the guide groove 2 of the energy-absorbing box of the automobile anti-collision bar. In this device, the dies 8 are arranged around, corresponding to the guide grooves 2 on each side of the crash box 6 one by one. The punching die 8 is installed on the slider 12 and reciprocates under the drive of the stamping cylinder 7 . The pressing force of the punching die 8 is very large, which can reach more than ten tons or even higher. Therefore, the core mold must be prevented from being stressed in one direction when the punching die 8 is being pressed in. The device connects the stamping oil cylinders 7 located on opposite sides of the mandrel to the same oil circuit, so that the pressure on both sides is consistent, which can ensure the synchronization of the punching dies 8 on both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com