Knurling machine

A knurling machine and motor technology, applied in metal processing machinery parts, driving devices, feeding devices, etc., can solve problems such as workpiece bending and increase processing costs, and achieve the effect of reducing maintenance costs, saving investment, and ensuring concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

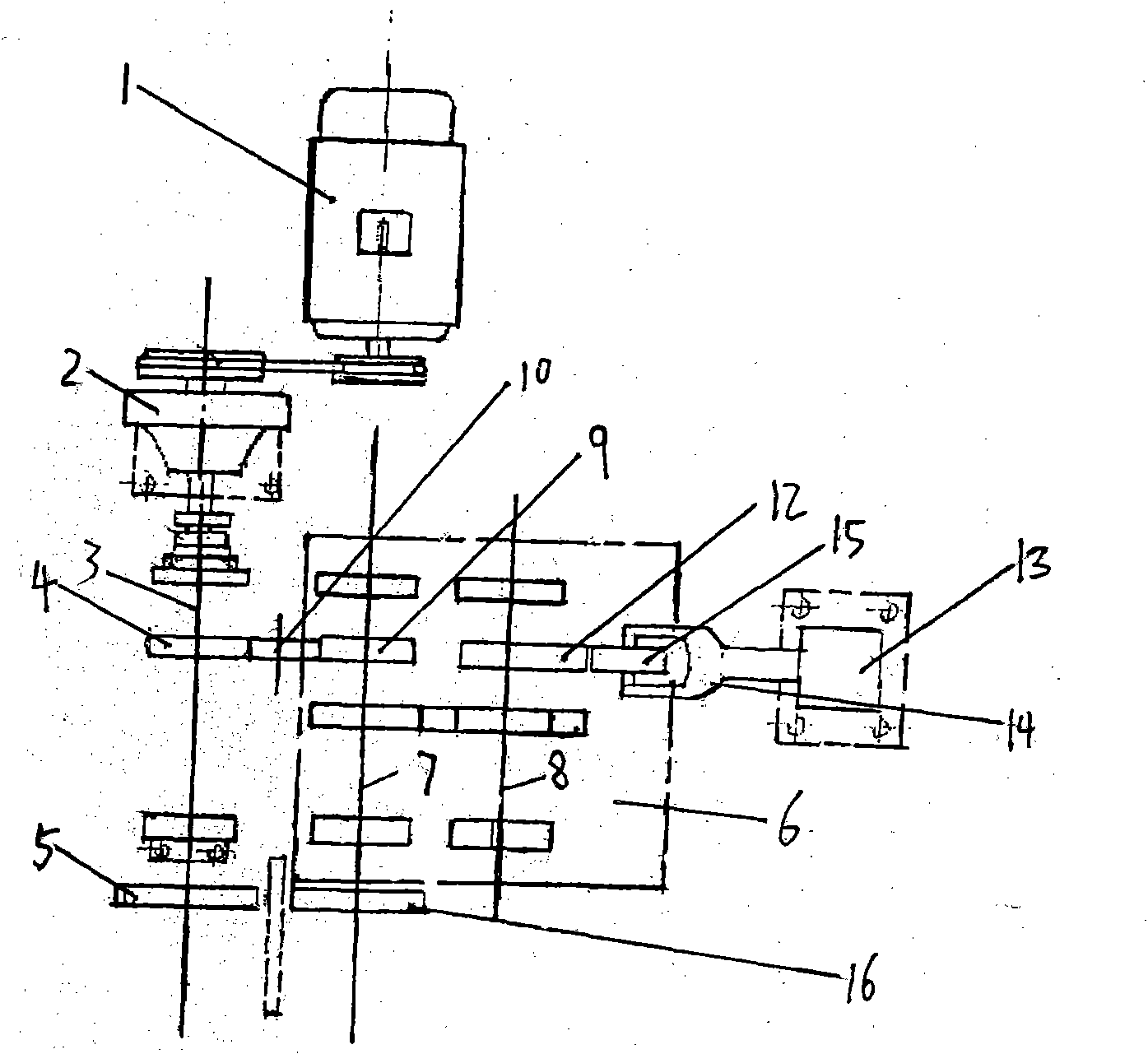

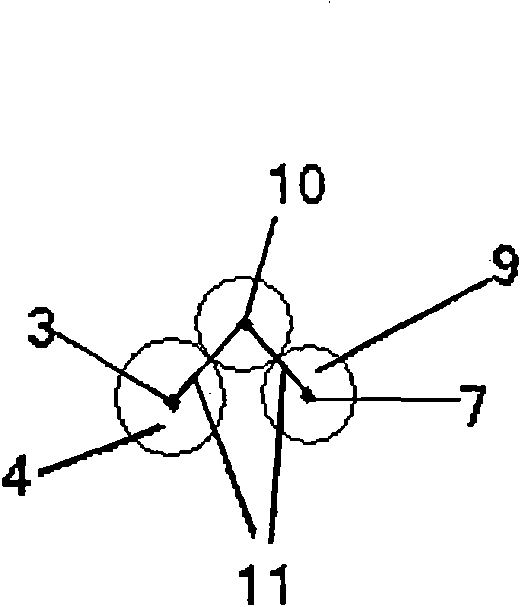

[0012] The knurling machine includes a motor 1 and a gear box 2, the motor shaft of the motor 1 is connected with the input shaft of the gear box 2, the output shaft of the gear box is fixedly connected with the working shaft 3, and the working shaft 3 is fixedly fitted with Gear one 4, the front end of the working shaft 3 is fixedly set with an active knurling wheel 5, and one side of the working shaft 3 is provided with a horizontal slide rail, and a slide plate seat 6 is slidably matched with it on the slide rail, and the slide plate seat 6 is The transmission shaft one 7 and the transmission shaft two 8 parallel to the working shaft 3 are rotated and installed, and the transmission shaft one 7 and the transmission shaft two 8 are connected through gear transmission; the transmission shaft one 7 is fixedly fitted with a gear two 9 and The passive knurling wheel 16 that cooperates with the active knurling wheel 5 has a central shaft 10 between the working shaft 3 and the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com