Pneumatic support device for steady operation of overlong boring cutter bar

A pneumatic support and stable work technology, applied in the field of mechanical processing, can solve the problems of decreased precision, tool cracking, and poor rigidity of long tool holders, etc., and achieve the effect of low cost, simple structure and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

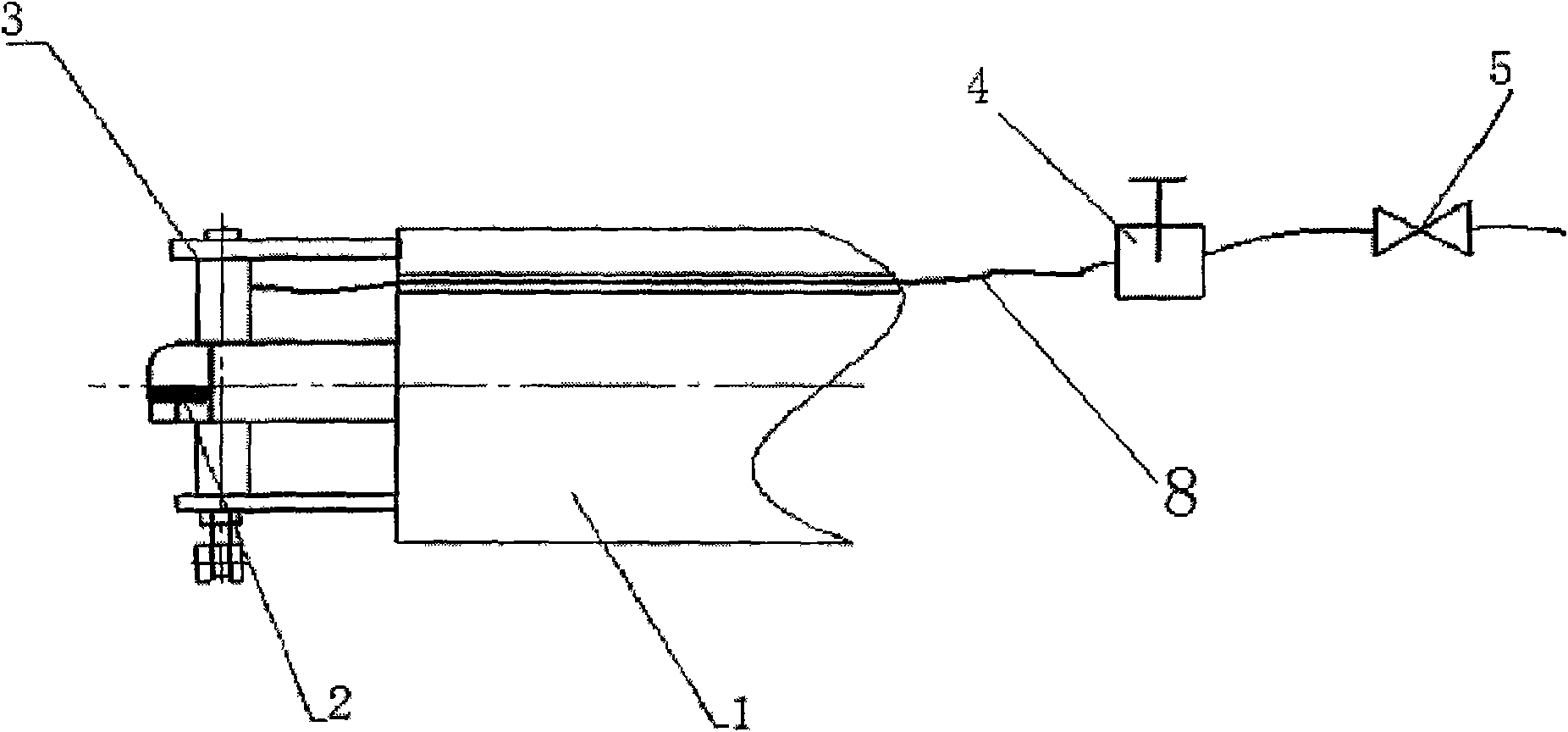

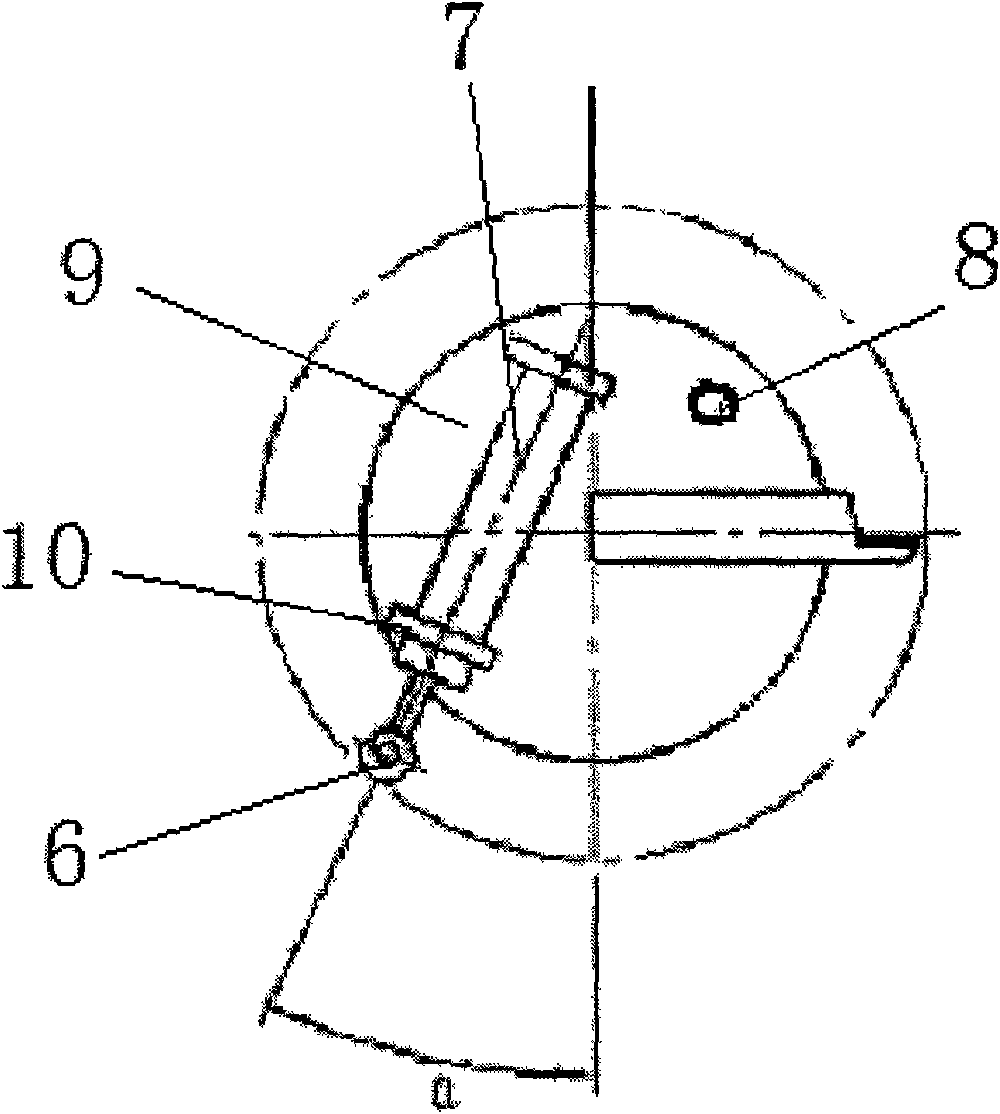

[0013] This embodiment is a pneumatic support device for the stable operation of an ultra-long boring bar, including a cylinder support 3 , a pressure regulating / stabilizing unit 4 , a switch 5 , a roller 6 , a cylinder 7 and an air pipe 8 . in:

[0014] Cylinder support 3 is made of 5 millimeters thick carbon steel plate, comprises two support plates 10 and a base plate 9. The bottom plate 9 is a circular plate with the same diameter as the outer diameter of the boring bar. The support plates 10 are two rectangular plates with the same structure. The external dimensions of the support plates 10 must meet the needs of installing the cylinder 7, and the support plates do not interfere with the bottom hole of the workpiece; there are cylinders at the ends of the two support plates 10. Mounting holes; the other ends of the two support plates 10 are fixed on the base plate, and are perpendicular to the surface of the base plate 9; the two support plates 10 are located on the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com