Sheet folding machine

A technology for folding machines and sheets, applied in the fields of folding machines and knife holders, which can solve the problems of inaccessibility, space occupation, and inaccessibility of the knife shaft, and achieve easy assembly and disassembly, reduced assembly and adjustment time, and easy assembly and disassembly fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

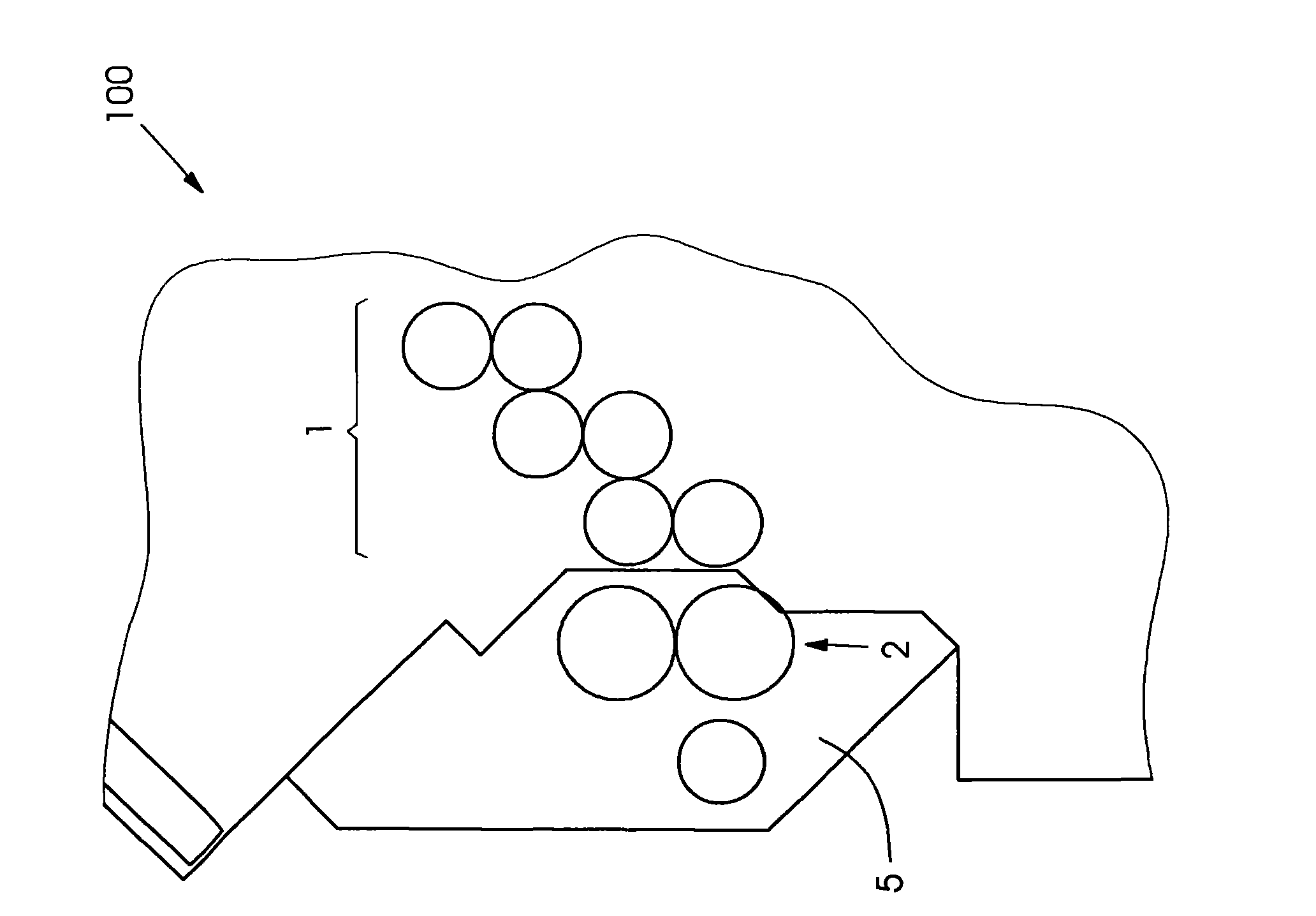

[0049] Folding machine 100's in figure 1 The exemplary embodiment schematically described in the figure relates to a fence folder for folding by means of a folding roller device 1 and a folding fence not shown here assigned to the folding roller device. Create multiple folded signatures. In this regard, several folding mechanisms are provided. Behind the last of these folding mechanisms is a pair of knife shafts 2 , which are mounted in separate roller housings 5 .

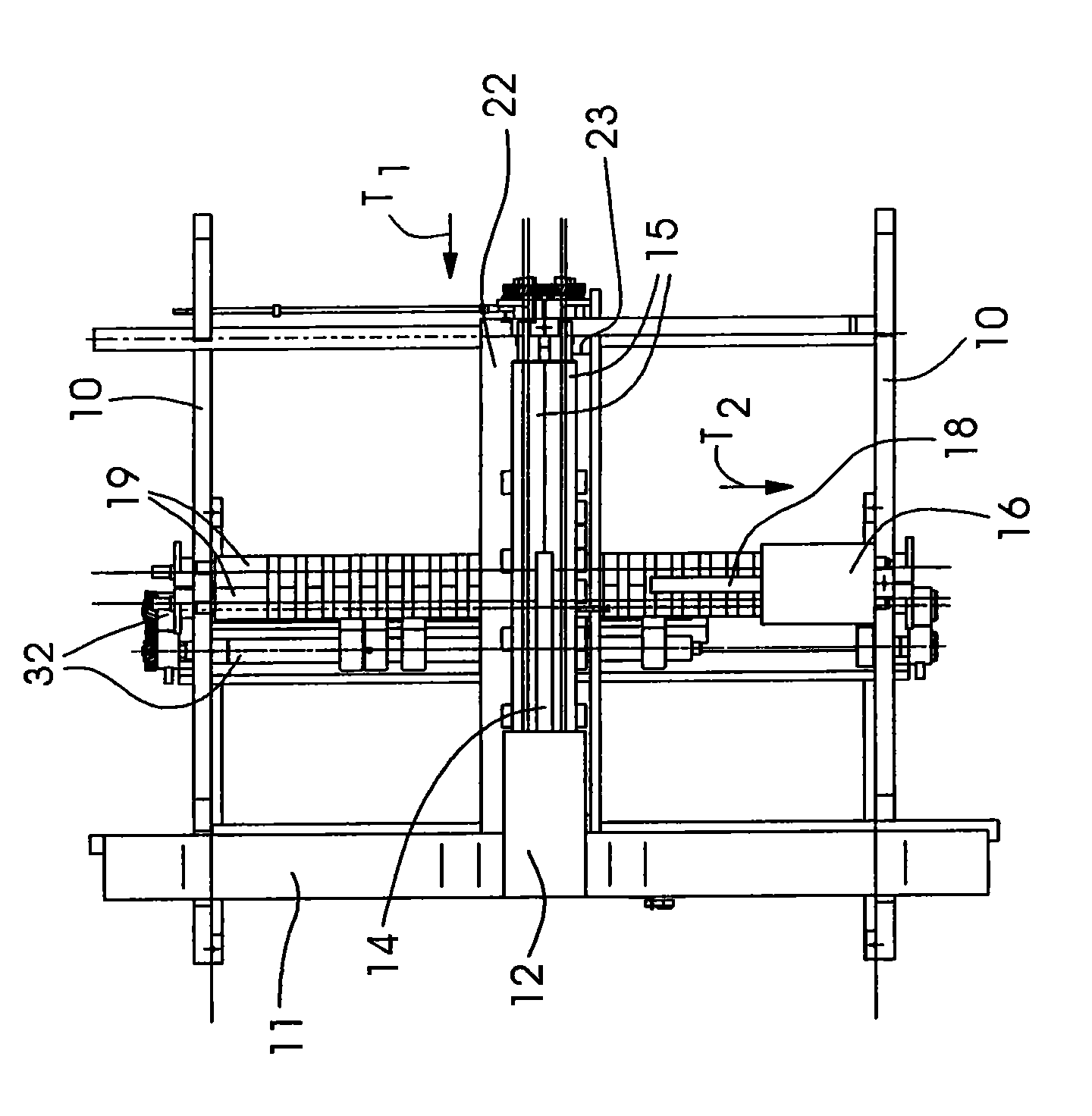

[0050] figure 2 A schematic plan view of the region of the knife folding mechanism of a preferred embodiment of the folding machine 100 according to the invention is shown. The knife folding mechanisms 12 , 14 , 15 , 16 , 18 , 19 themselves are also only shown schematically. exist figure 2 It can be seen in the folder 100 that two side walls 10 are spaced relatively parallel to each other, and these side walls are mainly connected to each other by a third side wall 11, wherein the third side wall 11 is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com