Short rzeppa synchronous universal coupling

A ball-cage, coupling technology, used in couplings, elastic couplings, mechanical equipment, etc., can solve the problems of high rigidity requirements of the transmission system, increased maintenance and use costs, and easy loosening of connecting bolts. The effect of reducing the difficulty of installation and adjustment, compact structure and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

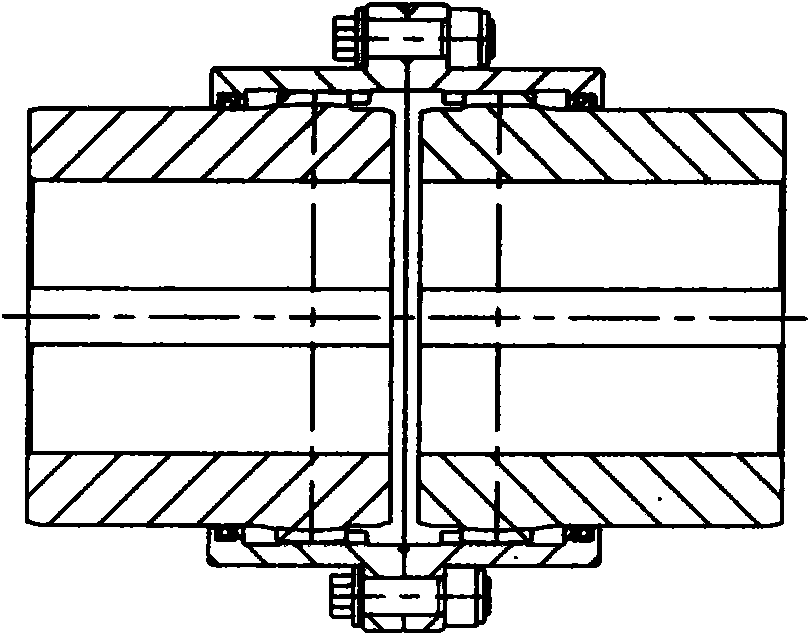

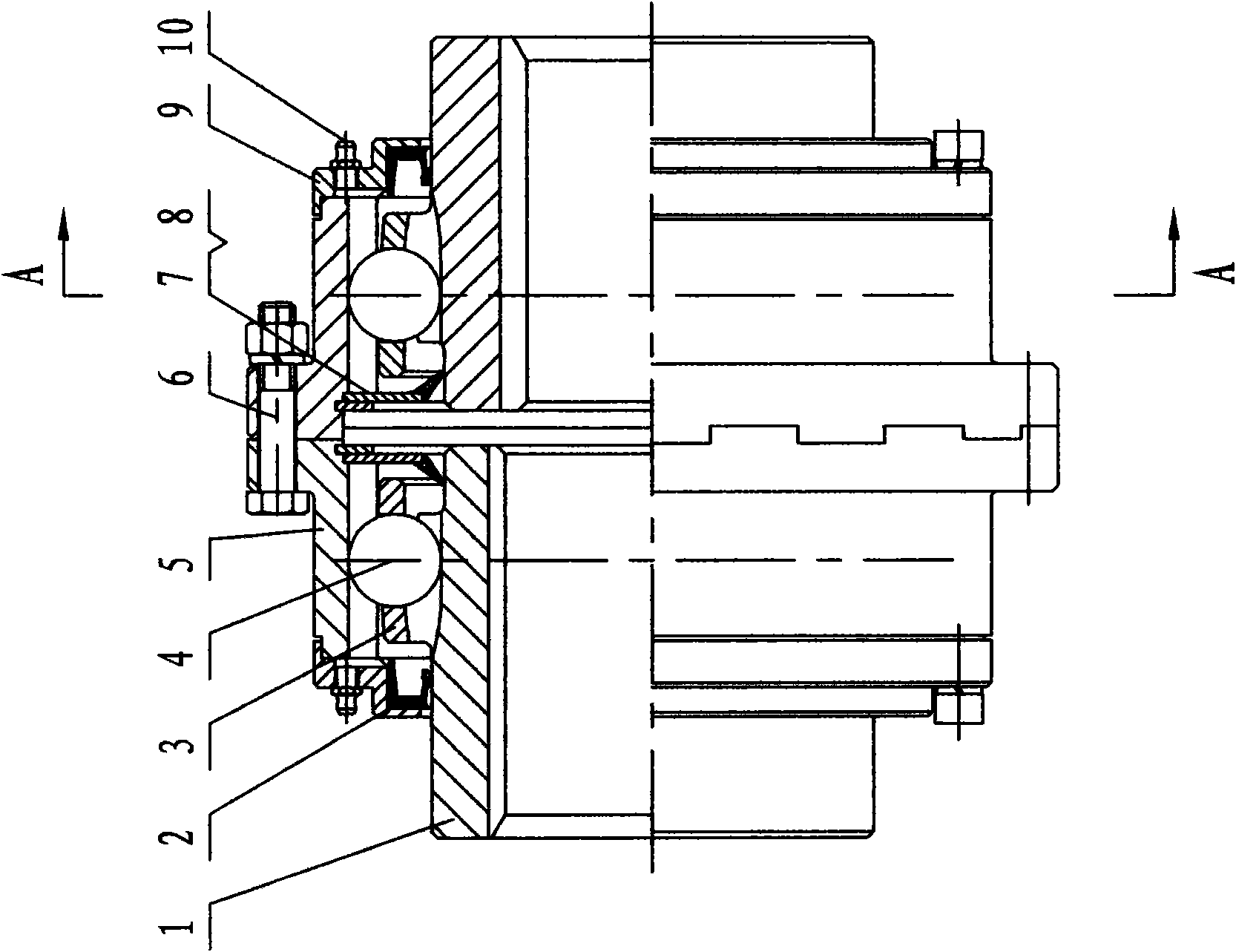

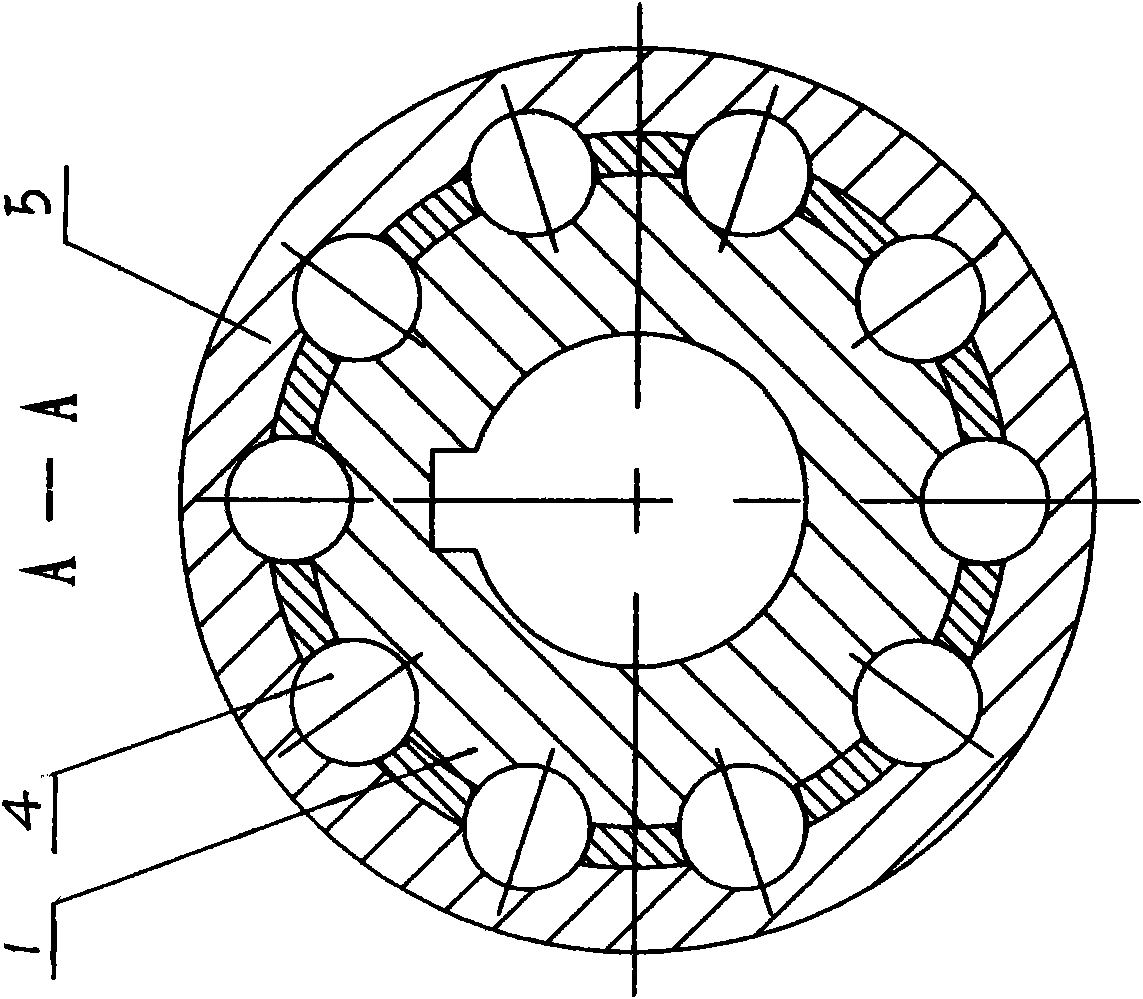

[0017] Such as figure 2 , image 3 As shown, the present invention is composed of an inner ring 1, an oil seal 2, a cage 3, a steel ball 4, an outer ring 5, a bolt 6, a sealing baffle 7, a retaining ring 8 for a hole, a gland 9, and an oil nozzle 10; the inner ring 1 There is a spline through hole or an inner hole with a keyway to cooperate with the corresponding shaft extension, and there is a spherical ring boss on the outer diameter of the inner ring 1, which is matched with the inner spherical surface of the cage 3. The inner ring 1 and the outer ring 5 Two groups of steel balls 4 are installed between them, and the specific number of steel balls 4 is determined by the required transmission capacity and internal geometric dimensions; there are multiple contact parts on the inner ring 1 and outer ring 5 that are in contact with the steel balls 4 and are evenly distributed along the circumference. Oval or circular straight channel, the torque is transmitted through the cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com