Method for preventing coal pulverizing system from exploding

A technology of pulverizing system and air pulverization, which is applied in the field of preventing coal mill explosion, and can solve problems such as explosion of pulverizing system and hidden dangers of pulverizing system safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In this embodiment, each working parameter is:

[0024] Grinding coal powder: Shenhua coal;

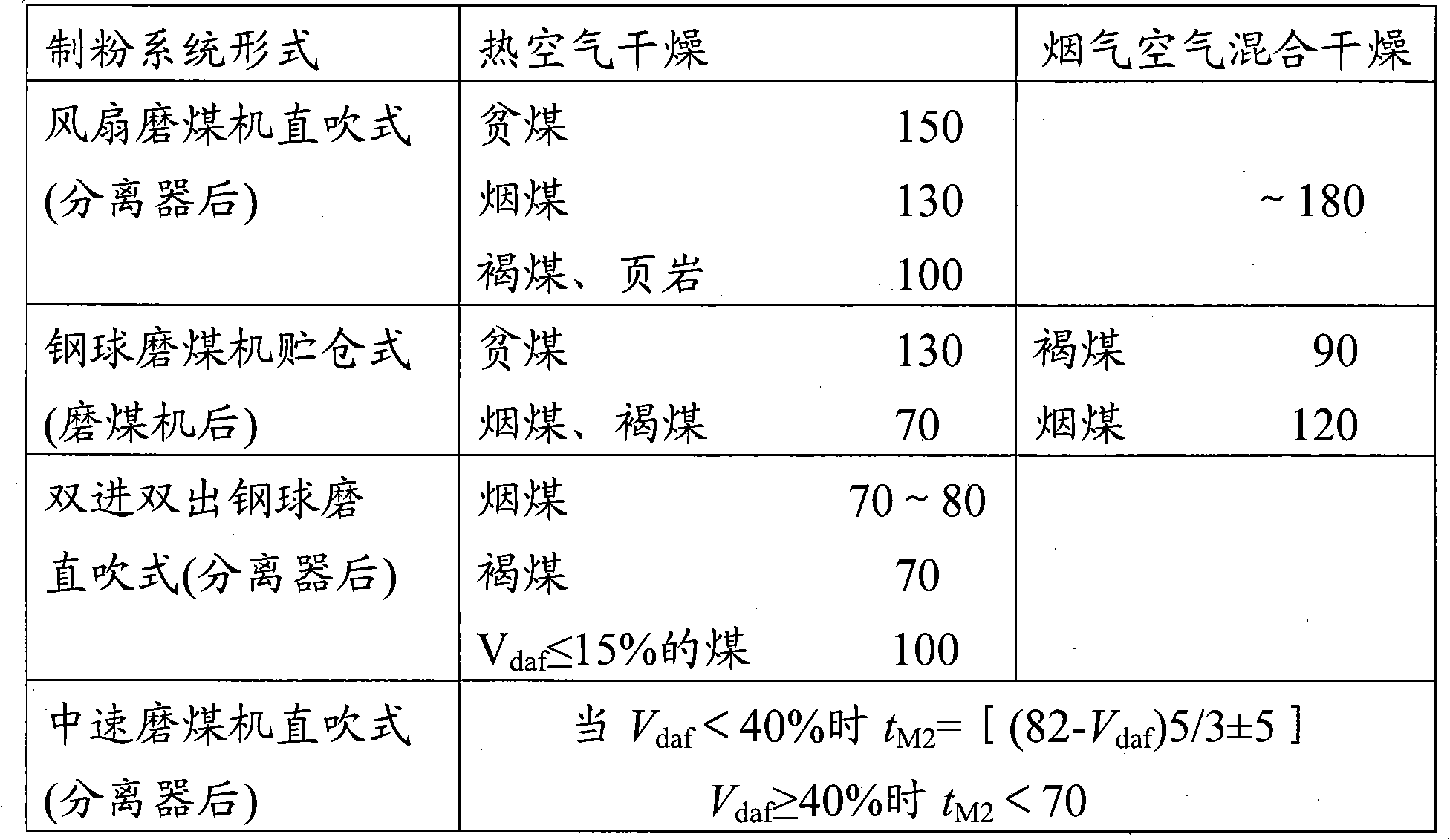

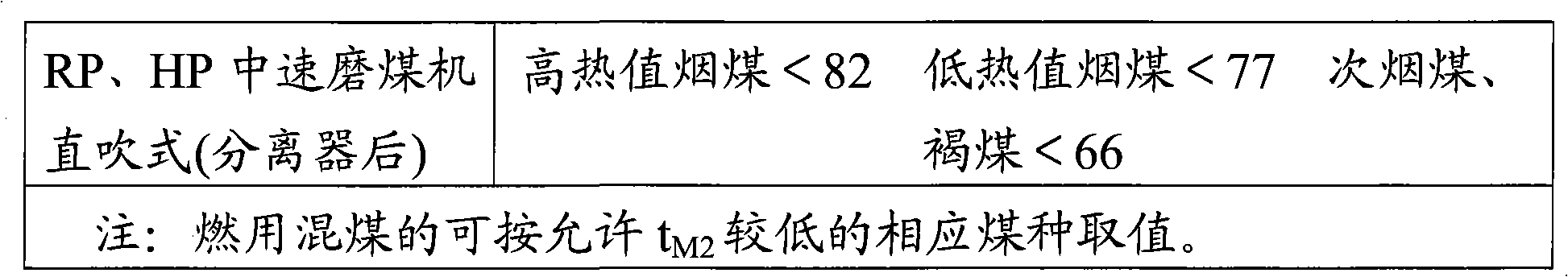

[0025] Pulverizing system: medium-speed HP mill, direct blown coal mill;

[0026] Coal mill outlet temperature: 65°C;

[0027] Primary air powder mixture temperature: 65°C; secondary air temperature: 300°C.

[0028] The method is simple in the actual operation of the power plant, and the operator of the power plant can control it through the switch of the damper. It is an important parameter related to security that is controlled at all times. According to the previously specified value, it is relatively high for Shenhua coal, and explosion accidents often occur. The power plant adopts this recommended value, and other operating conditions remain normal. The ignition and burnout of the boiler is not affected, and there is no deflagration in the pulverizing system due to high wind temperature. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com