A preparation process of composite heating plate for mold casting

A preparation process and a heating plate technology, applied in the field of refractory materials, can solve the problems of physical and mental health of operators, affecting the effect of heating plates, and pollution of molten steel quality, achieving good economic and social benefits, slowing down the burning start time, and good thermal insulation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

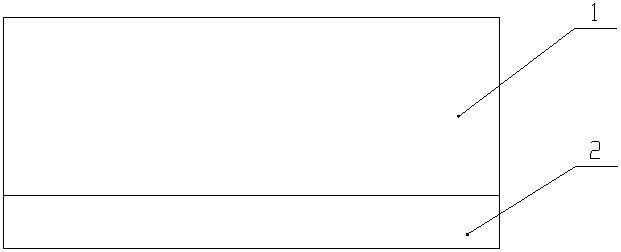

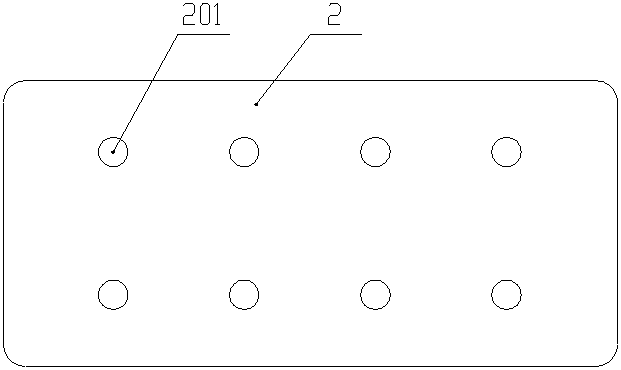

[0040] A preparation process of a composite heating plate for die casting, comprising a heating plate 1, an insulation plate 2 is arranged under the heating plate 1, the insulation plate 2 is the same length and width as the heating plate 1, and the height of the heating plate 1 is larger than the insulation plate 2. The four corners of the thermal insulation board 2 are provided with rounded corners A, and the length of the thermal insulation board 2 is provided with rows of equidistantly arranged thermal insulation holes 201, and the thermal insulation holes 201 in each row are along the width of the thermal insulation board 2. Directional arrangement; the four corners of the heating plate 1 are provided with round corners B, round corner B and round corner A have the same diameter, the raw material of the heating plate 1 is calculated by weight percentage, the raw material contains: 13% ~42% A1 metal aluminum powder, 4%~13% scorch dust, 5%~15% high power graphite, 6%~21% alum...

Embodiment 2

[0043] Example 2: The raw materials of the heating plate 1 are calculated by weight. The raw materials include: 118kg of Al metal aluminum powder, 39kg of coke dust, 45kg of high-power graphite, 63kg of aluminum ash, 27kg of high-power perlite, and 18kg of gold ore powder , 66kg of waste paper, 60kg of starch, 54kg of sodium fluoride, 60kg of wood chips, 24kg of carbonized chaff, 21kg of fluorite powder, 108kg of 281 strong glue;

[0044] The raw materials of the insulation board 2 are calculated by weight, and the raw materials include: 63kg of aluminum ash, 30kg of coke dust, 15kg of waste paper, 27kg of wood chips, 30kg of starch, 18kg of sodium fluoride, 15kg of fluorite powder, 45kg of 281 strong glue, 18kg of carbonized chaff;

[0045] Including the following steps;

[0046] A), the raw material mixture of heating plate 1 is stirred,

[0047] ① Mix the raw materials of the heating plate 1 and start the mixing mixer, and put the raw material of the heating plate 1 in the above c...

Embodiment 3

[0071] Embodiment 3 The raw materials of the heating plate 1 are calculated by weight percentage, and the raw materials include: 13% to 42% of Al metal aluminum powder, 4% to 13% of coke dust, 5% to 15% of high-magnification graphite, 6%-21% aluminum ash, 2%-9% high-magnification perlite, 1%-12% gold ore powder, 7%-25% waste paper, 5%-25% starch, 3%-18% % Sodium fluoride, 5%-20% wood chips, 2%-8% carbonized chaff, 2%-7% fluorite powder, 10%-36% 281 strong glue, 5%-23% chemical Slurry

[0072] The raw materials of the thermal insulation board 2 are calculated by weight percentage, and the raw materials include: 10%-30% aluminum ash, 5%-12% scorch, 3%-10% waste paper, 9%-13% Sawdust, 6% to 15% starch, 3% to 9% sodium fluoride, 3% to 10% fluorite powder, 5% to 10% 281 strong glue, 6% to 8% chemical slurry, 2 %~10% carbonized chaff.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com