Gas cover type integrated environment-friendly stove and gas cover smoke exhaust method

A technology that integrates environmentally friendly stoves and gas hoods. It is applied to household stoves, heating methods, and oil fume removal. It can solve problems such as non-environmental protection, noise, and low exhaust efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

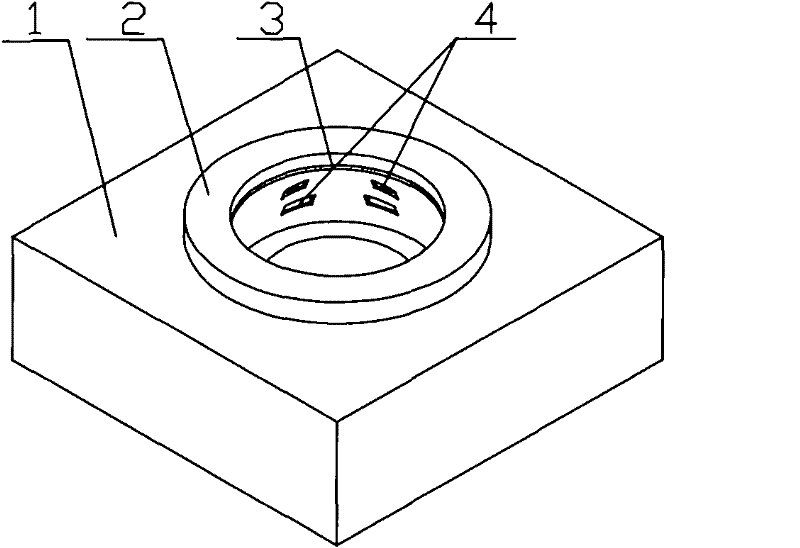

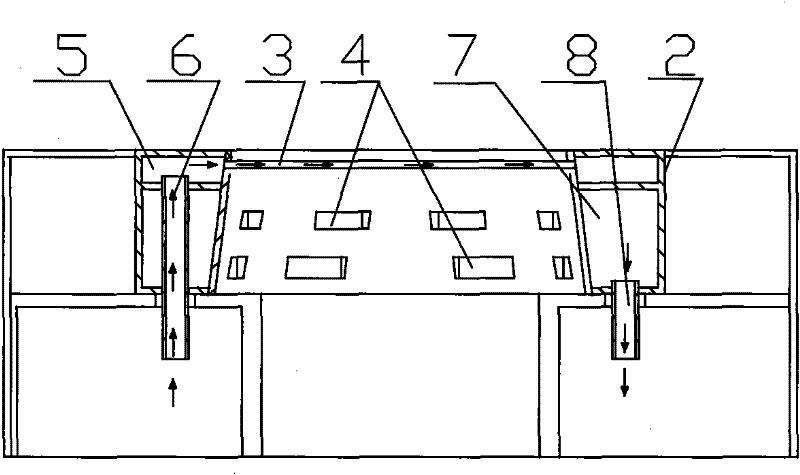

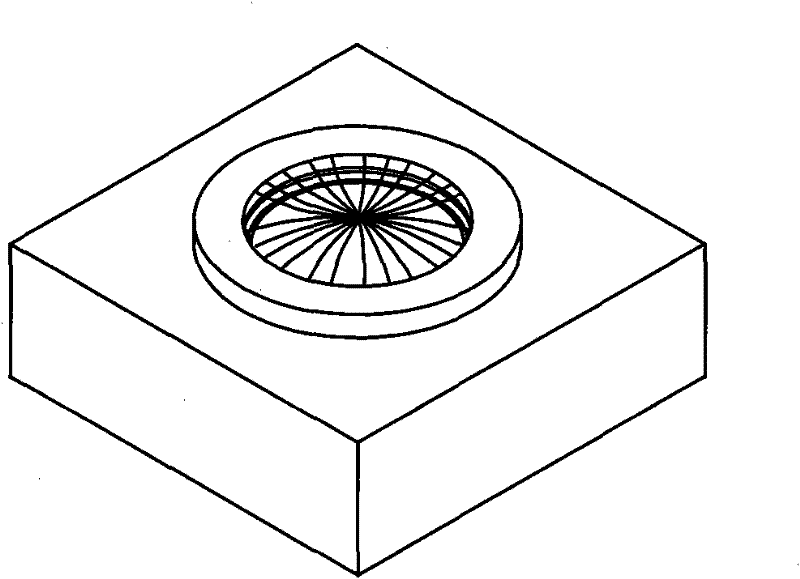

[0019] Embodiment 1: with reference to attached figure 1 and 2 . Gas hood type integrated environmental protection stove, which includes a fluid diaphragm smoke and dust suction and exhaust device 2 and a stove 1, the fluid diaphragm smoke and dust suction and discharge device 2 is composed of a positive pressure gas ring 5 and a negative pressure gas chamber 7, and the positive pressure gas ring 5 is located in the negative pressure gas chamber 7, the positive pressure air ring 5 communicates with the air outlet of the fan through the air supply pipe 6, and the negative pressure air chamber 7 communicates with the air extraction port of the air extractor through the air suction pipe 8, and the inner side of the positive pressure air ring 5 is provided with a fluid outlet 3 or A helical fluid outlet is opened, and a plurality of fluid suction ports 4 are opened circumferentially on the inner side of the negative pressure chamber 7 and are located below the annular fluid outle...

Embodiment 2

[0021] Embodiment 2: On the basis of Embodiment 1, the upper inclination angles of multiple fluid suction ports 4 are 0 to 25 degrees and include the end values, that is, such as 0 degrees, 0.5 degrees, 1.0 degrees, 1.5 degrees, 2.0 degrees, 2.5 degrees, 3.0 degrees, 3.5 degrees, 4.0 degrees, 4.5 degrees, 5.0 degrees, and so on to 25 degrees.

Embodiment 3

[0022] Embodiment 3: On the basis of Embodiment 1, the left and right inclination angles of multiple fluid suction ports 4 are 0 to 25 degrees and include the end values, that is, such as 0 degrees, 0.5 degrees, 1.0 degrees, 1.5 degrees, 2.0 degrees, 2.5 degrees, 3.0 degrees, 3.5 degrees, 4.0 degrees, 4.5 degrees, 5.0 degrees, and so on to 25 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com