Production monitoring system based on rfid

A monitoring system and radio frequency identification technology, applied in the direction of cooperative devices, instruments, data processing applications, etc., can solve the problems of not paying attention to operators, not tracking and monitoring production data, not checking the production process, etc., to reduce inventory and Waste of manpower, ensure integrity, and facilitate offline verification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

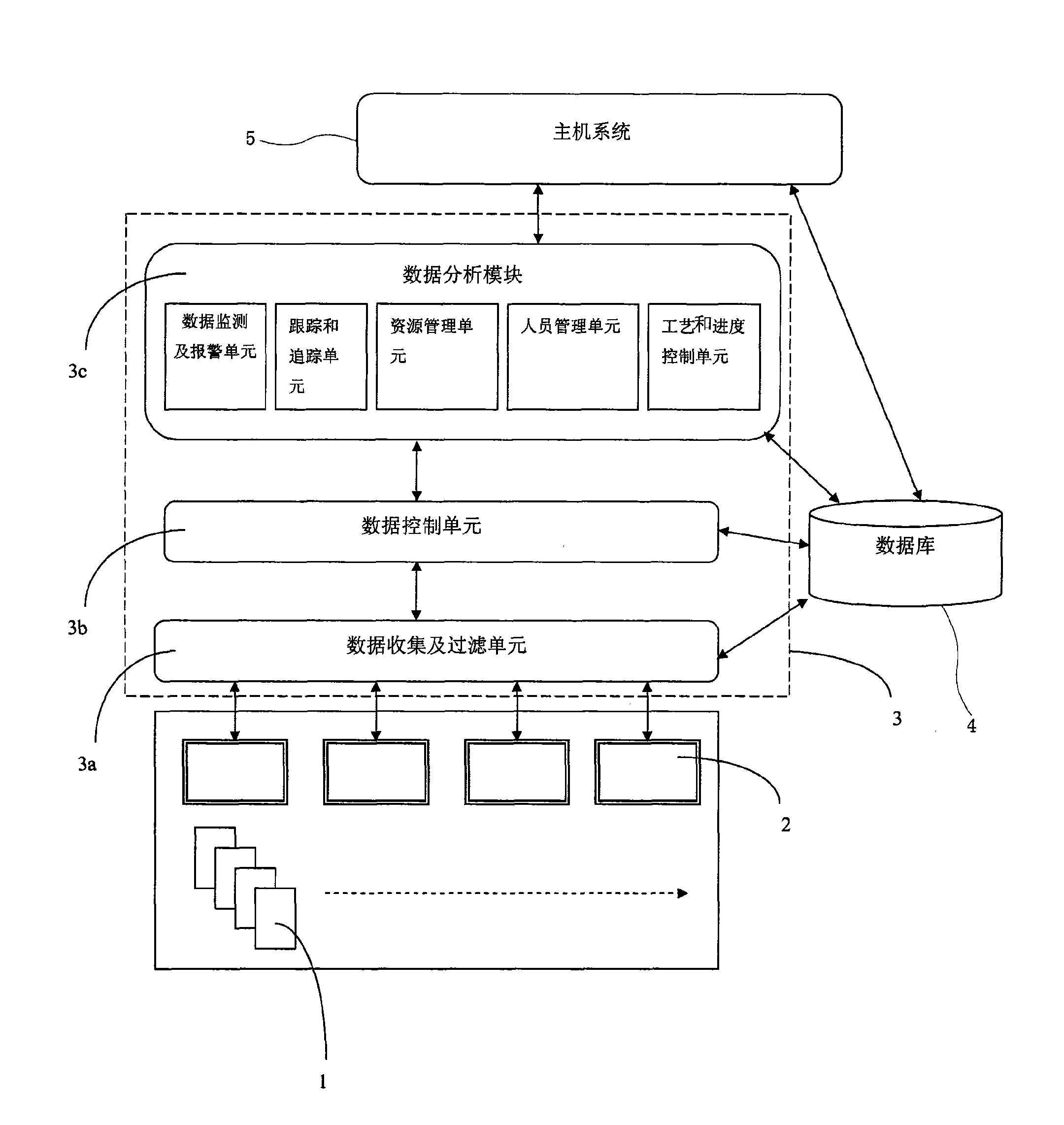

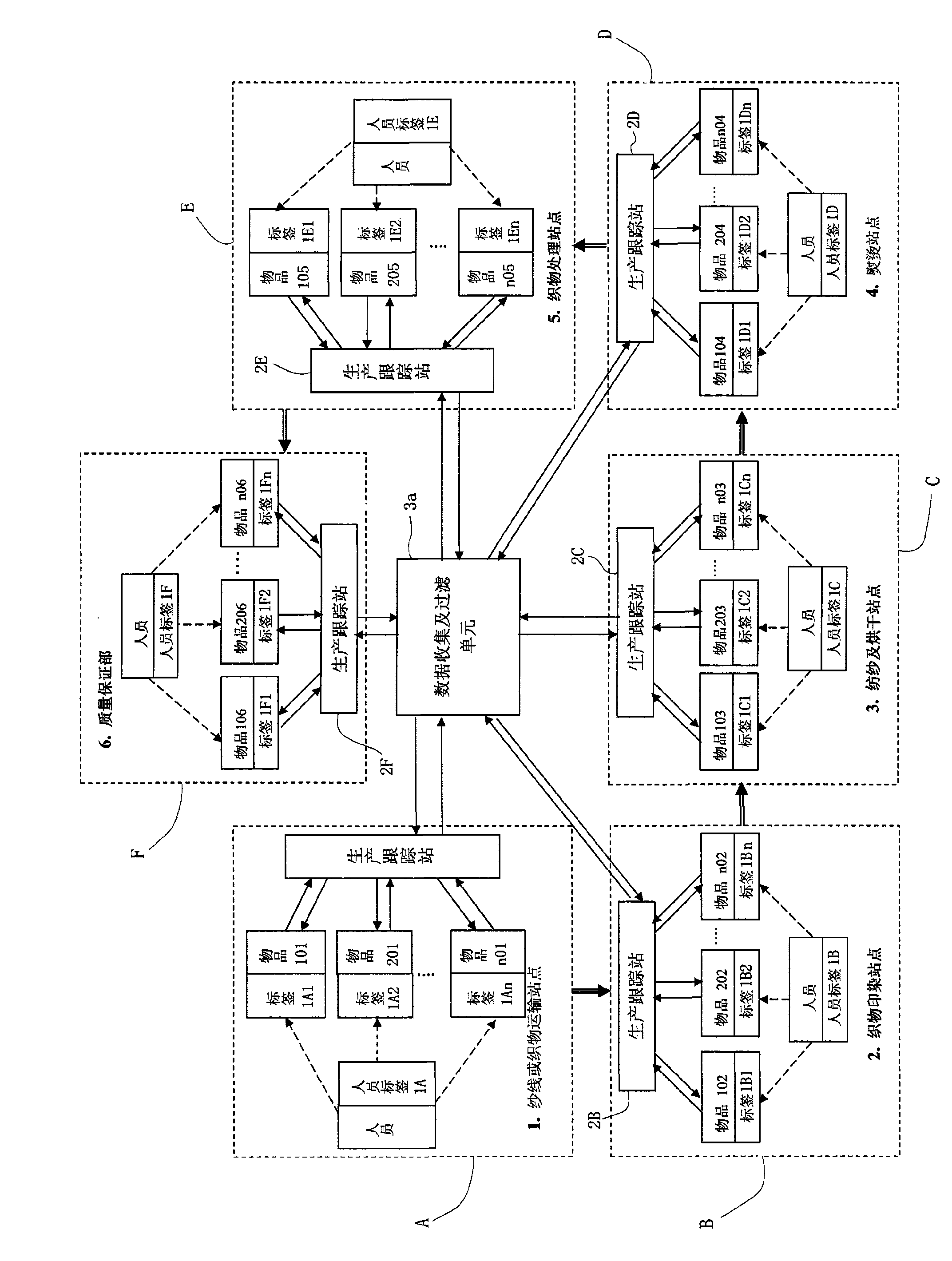

[0062] refer to figure 1 , the production monitoring system based on radio frequency identification of the present invention comprises a plurality of radio frequency identification tags 1, a plurality of production tracking stations 2, a comprehensive monitoring software module 3, a database 4 and a host system 5, wherein:

[0063] A plurality of radio frequency identification tags 1 are attached to the product in progress, and the data of the tags 1 can be read and written at a production tracking station.

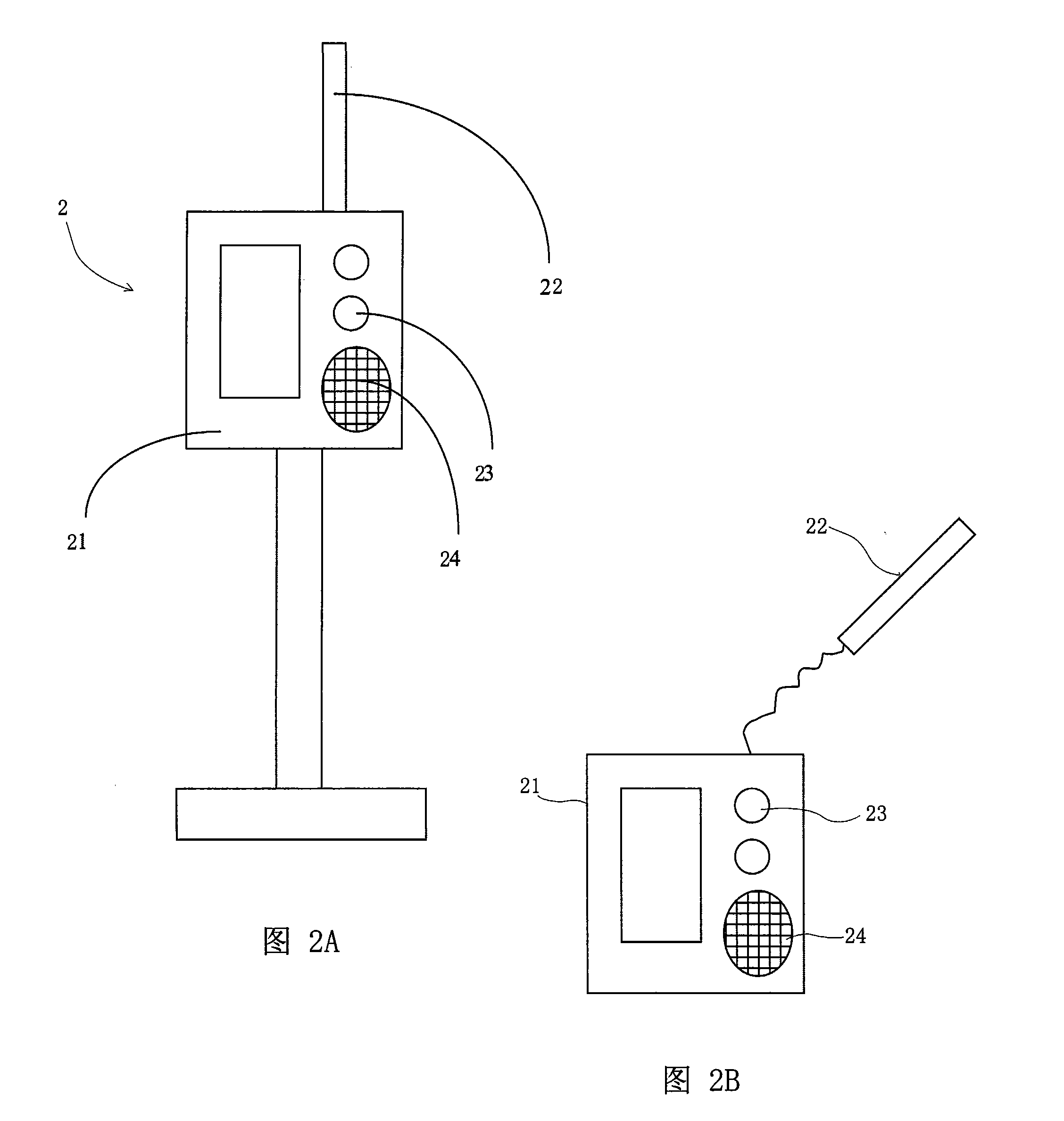

[0064] A plurality of production tracking stations 2, the structure of which is shown in 2. Such as Figure 2A , the production tracking station 2 includes an interrogator 21, an antenna 22, a light emitting diode (LED) 23 and a buzzer 24, and the interrogator 21 is used for reading and writing data from the tag. The antenna 22 is connected to the interrogator 21 for receiving or sending out radio waves. Such as Figure 2B As shown, the antenna 22 can be extended to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com