Liquid supplying and draining device of evaporating and cooling system of water wheel generator stator

A technology for generator stators and hydroelectric generators, applied in cooling/ventilation devices, electromechanical devices, electrical components, etc., can solve the problems of hidden dangers in use, large dielectric loss, time-consuming and labor-intensive problems, and reduce intermediate losses and facilitate Control and ensure the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

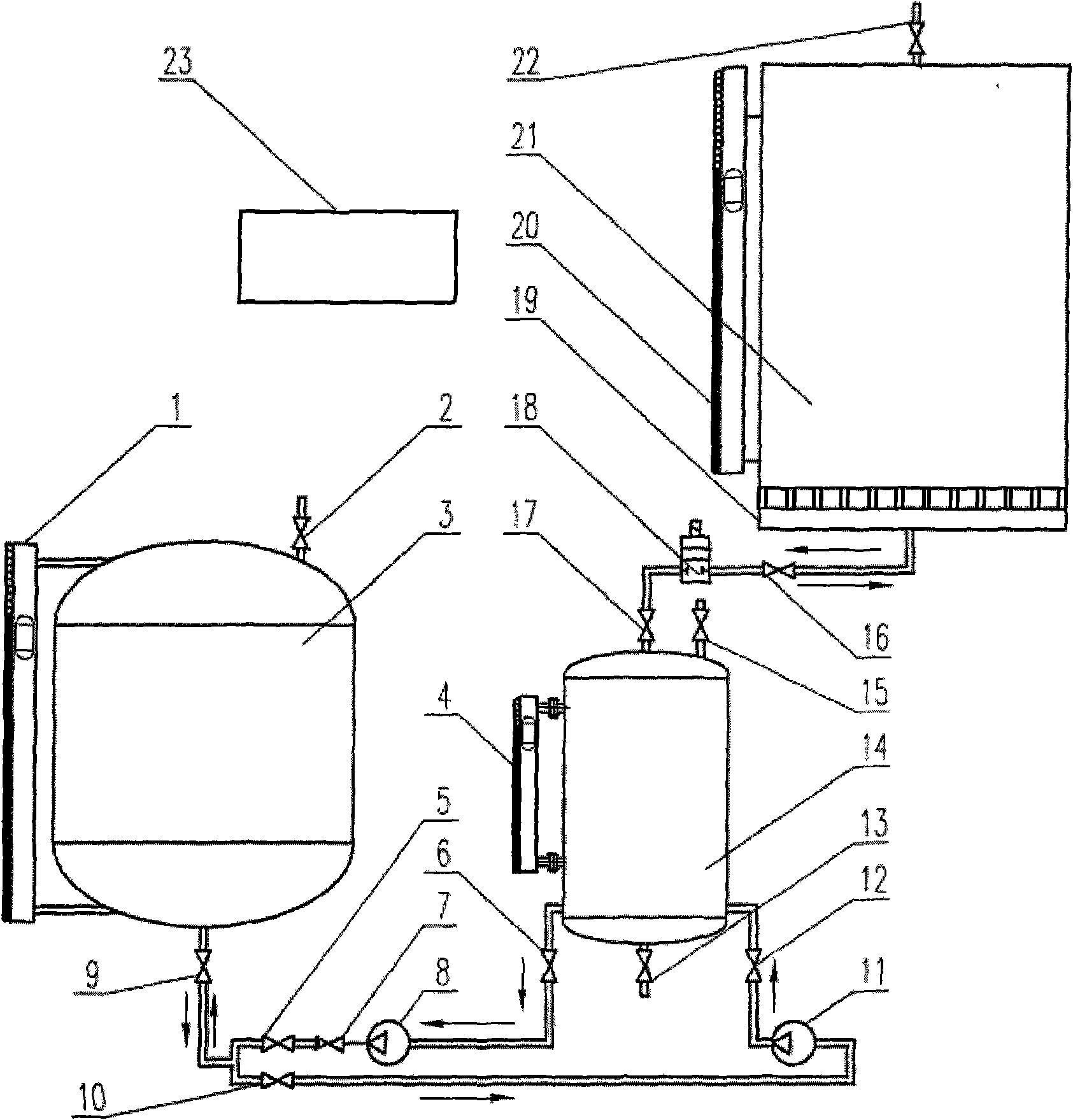

[0025] The liquid supply and discharge device of the present invention comprises a liquid supply branch, a liquid discharge branch and a power / control cabinet (23) for providing a power supply and a control circuit.

[0026]figure 1 is an embodiment of the present invention. Such as figure 1 As shown, a stainless steel pipe fitting is welded at the lowest position of the liquid collecting pipe 19, and a flange is welded at the other end of the pipe fitting, and the device of the present invention is installed on the stator evaporative cooling system 21 of the hydro-generator through the flange ball valve 16. A liquid level gauge 20 and an air release valve 22 are installed on the stator evaporative cooling system 21 of the hydro-generator, and the position of the entire liquid supply and discharge device is lower than the liquid collection pipe 19 . The liquid supply / discharge solenoid valve 18 is connected to the liquid collecting pipe 19, and an inspection valve 16 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com