Structure of fuel supply part

A technology of supply part and fuel, which is applied to the layout, vehicle components, power plant, etc. combined with the fuel supply of internal combustion engines, which can solve the problems of water intrusion and difficulty in stabilizing the tip accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

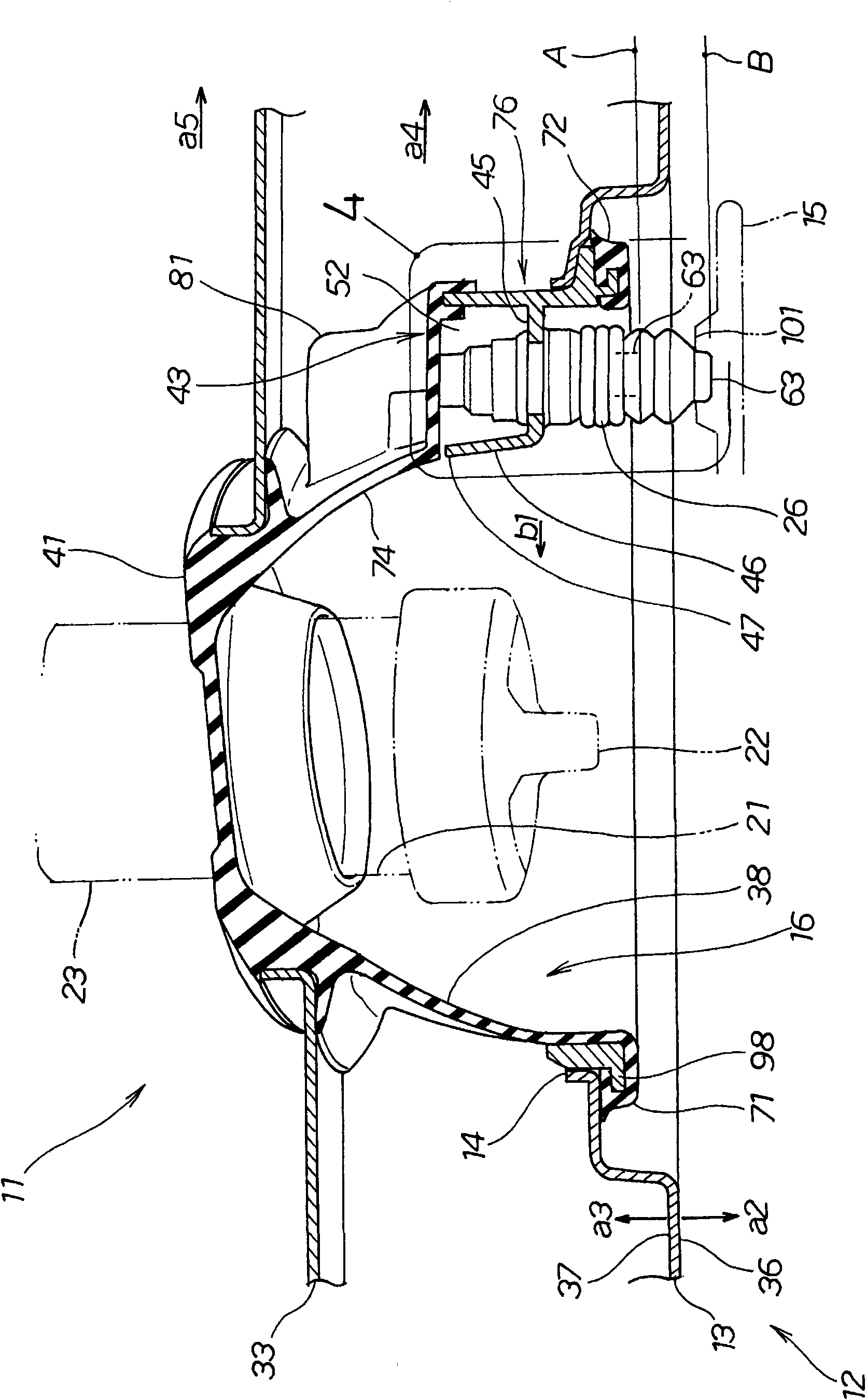

[0047] The best mode for use in the present invention will be described with reference to the drawings.

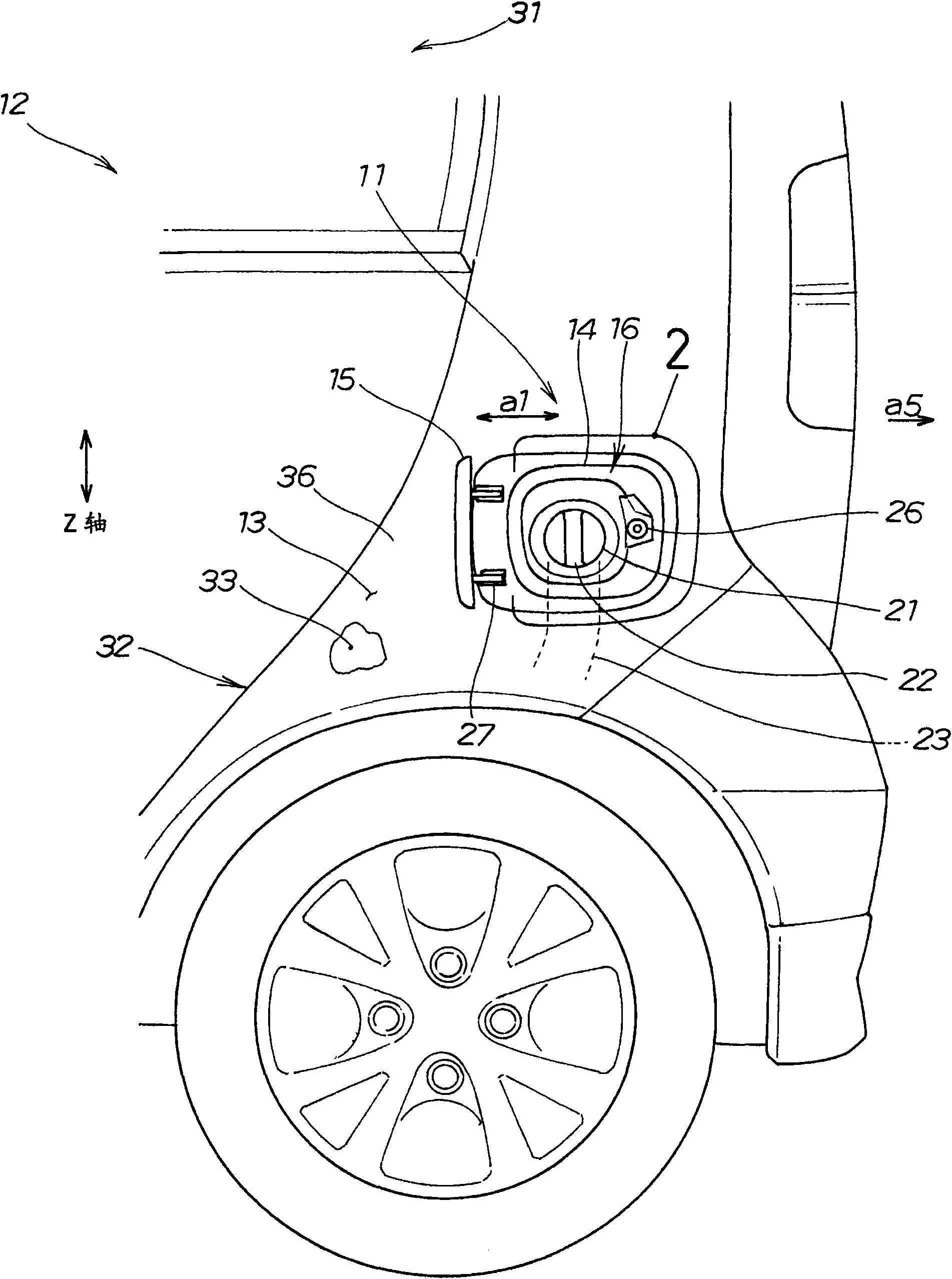

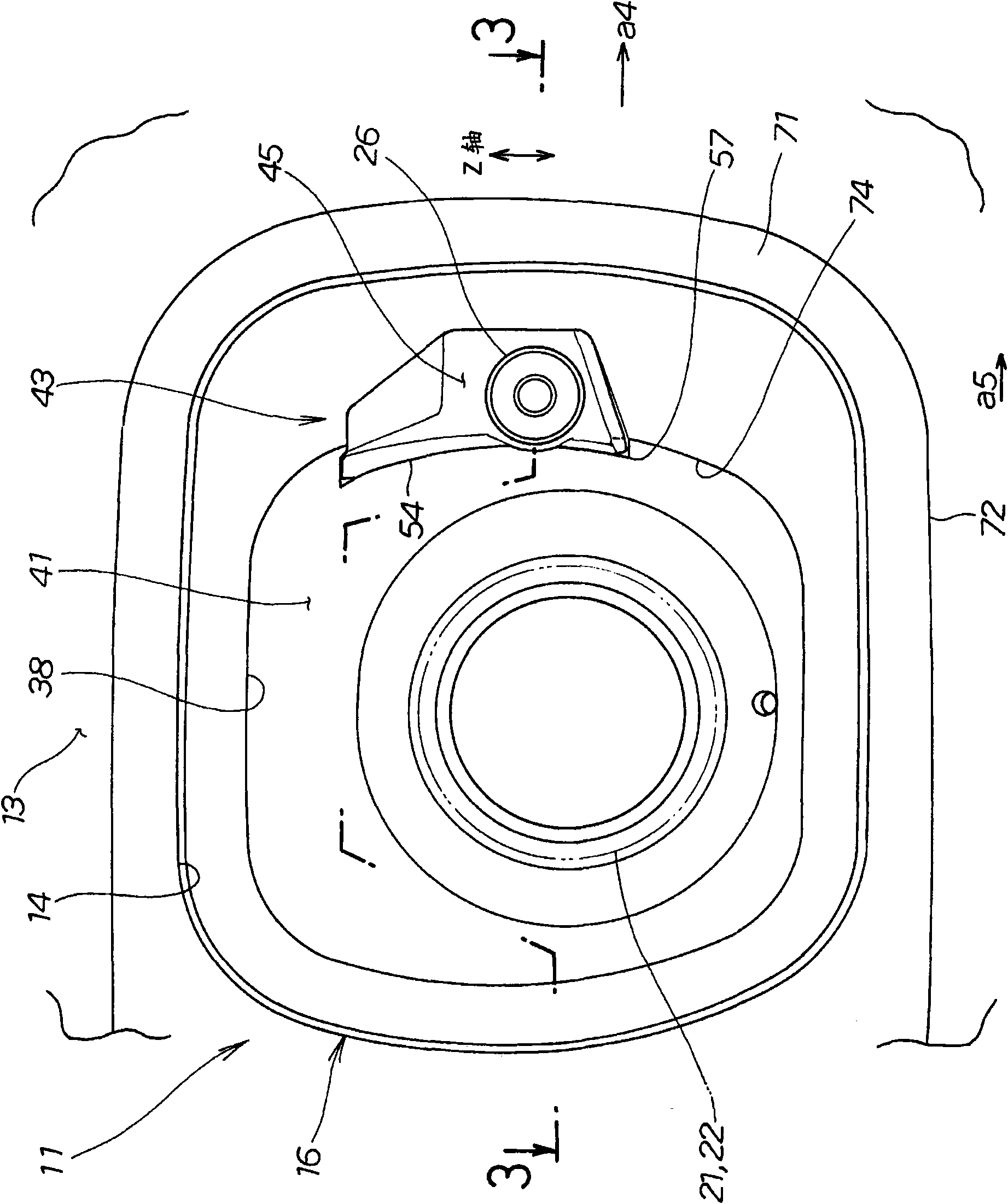

[0048] figure 1 It is a front view of the structure of the fuel supply part of this invention.

[0049] The fuel supply part structure 11 is used on the vehicle 12 and has: a fuel cap 15 provided on the opening 14 of the outer panel 13 of the vehicle 12 in a freely openable and closable manner (in the direction of the arrow a1); A substantially box-shaped fuel adapter 16 and a fuel supply port 21. 22 is a cap of the fuel supply port 21, and 23 is a fuel supply pipe for introducing fuel from the fuel supply port 21 to a fuel tank (not shown).

[0050] The operation when supplying fuel is the same as usual. First, the lock is released, and then, the closed fuel cap 15 is pushed from the outside, and the fuel cap 15 is opened by the pushing member 26 (refer to image 3 ). Fully open the fuel cap 15 by hand until the end ( figure 1 state) for oil supply.

[0051] The fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com