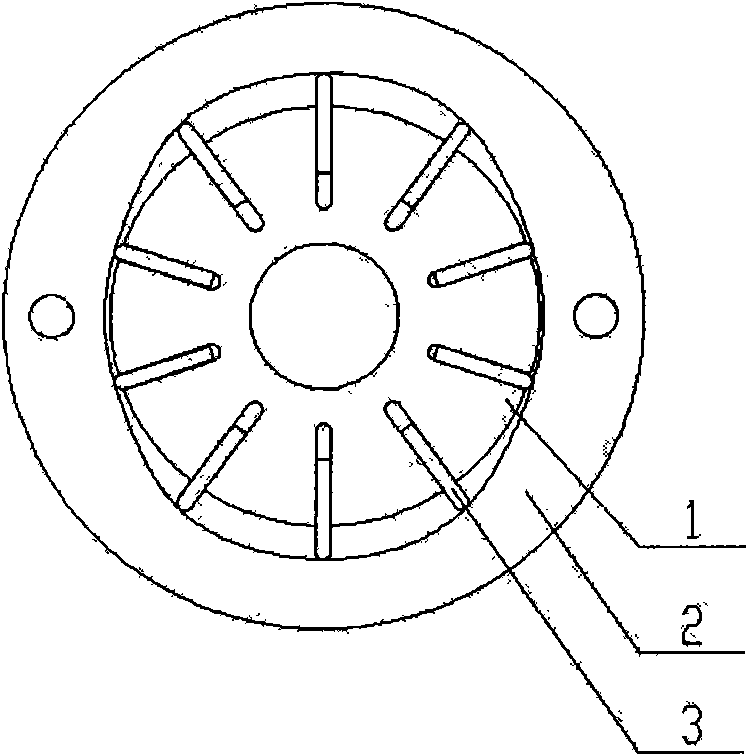

Processing method of vane pump rotor groove

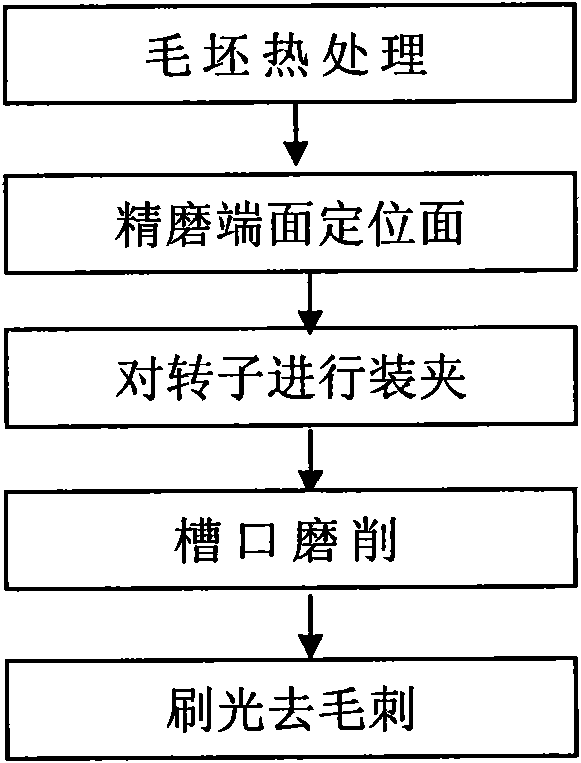

A processing method and rotor groove technology, applied in metal processing equipment, pump control, manufacturing tools, etc., can solve the problems of low production efficiency, worn surface roughness, low processing accuracy, etc., to avoid uneven grinding , Good surface roughness, the effect of product quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

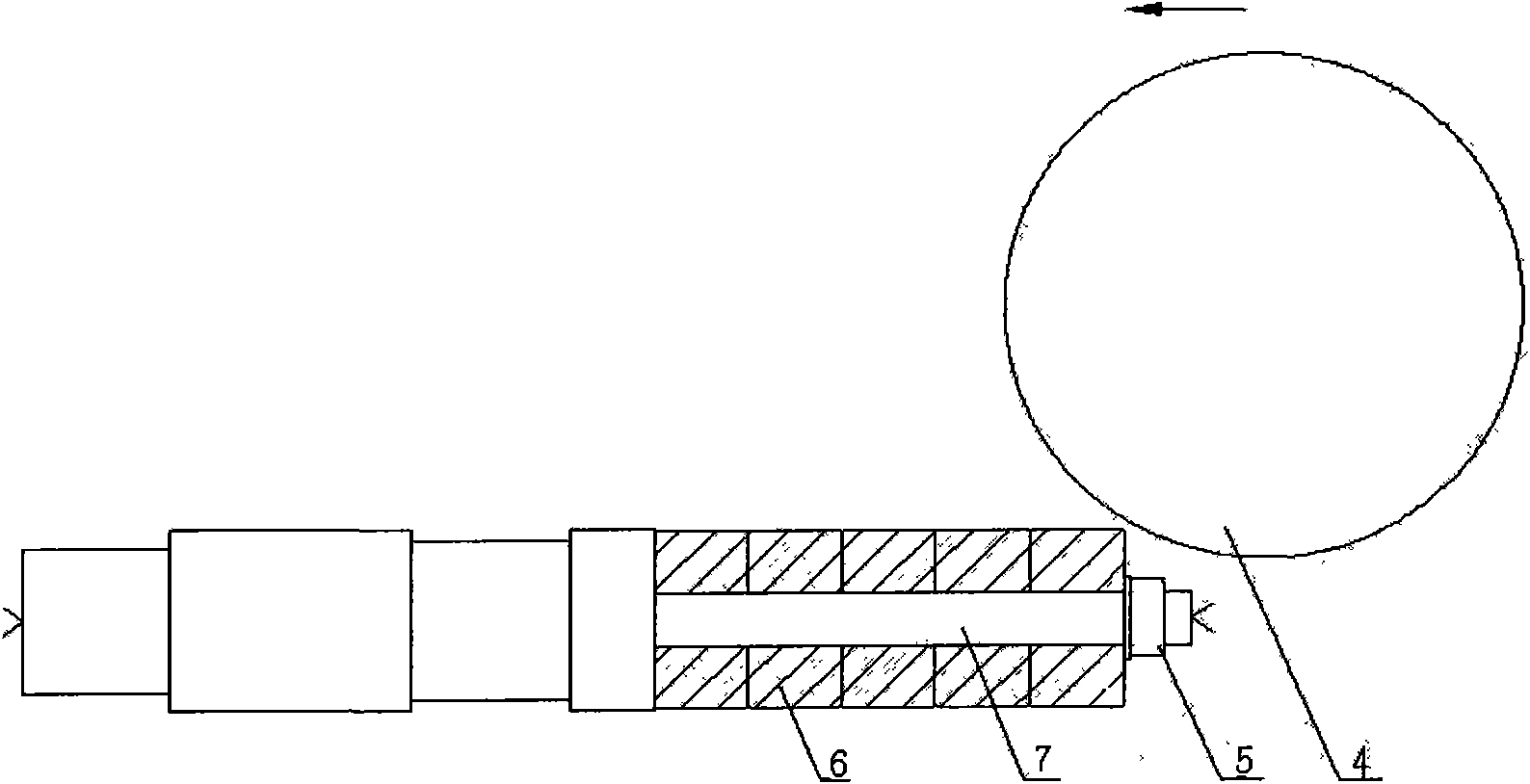

[0027] The rotor used for steering pumps in the automotive industry, the material is GCr15, after the process test, the pre-processed spline inner hole φ9.23+0.01 is obtained, and the vacuum quenching furnace is used for heat treatment to ensure that the bottom diameter after heat treatment is φ9.3+0.015. The blank after heat treatment is clamped with a mandrel, and the mandrel is divided into two levels of φ9.3+0.01 and φ9.3-0.01 for use.

[0028] Before clamping, the two ends of the rotor blank are ground, and the parallelism is required to be less than 0.005mm. according to image 3 The clamping method shown is for clamping, and the five rotors are installed on the mandrel, and the nuts are used to compress it. Both ends of the mandrel are anti-thimbles, and the hydraulic cylinder drives the thimble to fix the mandrel.

[0029] The processing of this product adopts the cubic boron nitride grinding wheel with vitrified bond, the particle size is 80, the concentration is 200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com