Electroluminescence fabric

A technology of electroluminescence and light-emitting layer, applied in the field of flat light-emitting cloth devices, which can solve the problems of inability to use directly, bend and cut at will, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

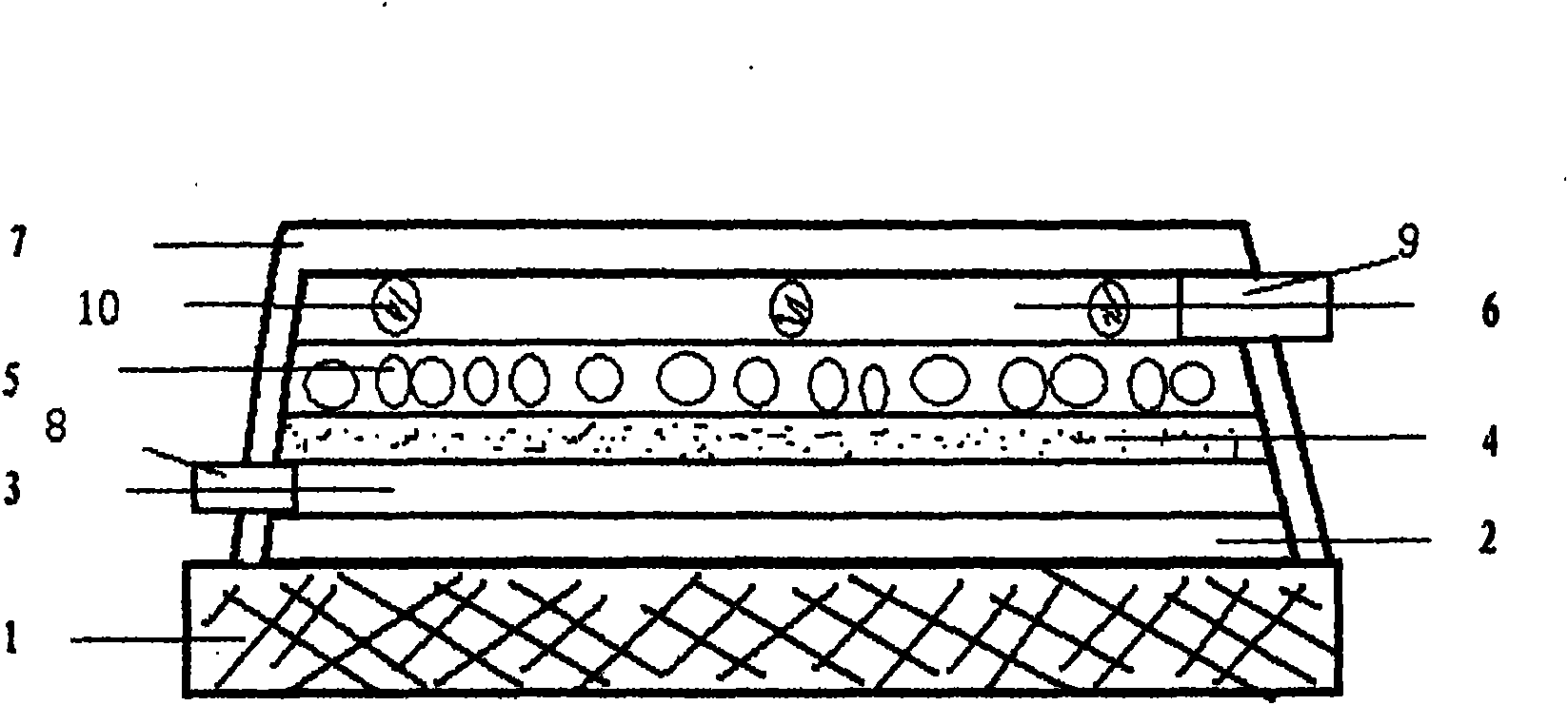

[0028] A continuous dense plane of silk (1). Surface screen printing waterproof fluorine paint protective layer substrate layer, thickness 0.5 microns; dry at room temperature. On the silver layer of the conductive material of the silk screen printing base, the thickness is 2 microns, and it is dried at room temperature.

[0029] Take 10 grams of BaTiO powder and add it to 10 grams of fluorine paint glue. After mixing, evenly screen-print on the surface of the waterproof layer with a thickness of 3 microns and dry at room temperature.

[0030] Take 15 grams of D513 type electroluminescent powder, mix it with 15 grams of fluorine paint colloid, and evenly screen-print it on the surface of the medium layer, with a thickness of 5-30 microns, and dry it at room temperature.

[0031] The transparent conductive layer is made of ITO with a thickness of 0.5 microns, sprayed and dried at a temperature of 40 degrees.

[0032] The material of the transparent outer protective layer is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com