One-step electrochemical preparation method of graphene/polyaniline flexible electrode

A flexible electrode and polyaniline technology, applied in the direction of hybrid capacitor electrodes, circuits, electrical components, etc., can solve the problems of heavy weight, inconvenience, easy breakage and transportation of glass substrates, and achieve simple manufacturing process, high conductivity, and controllability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

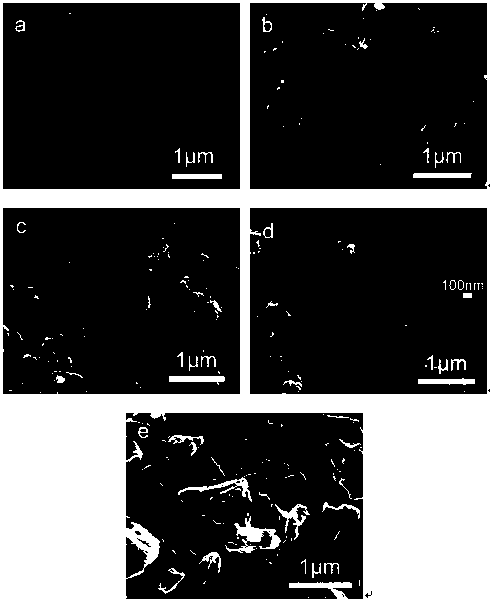

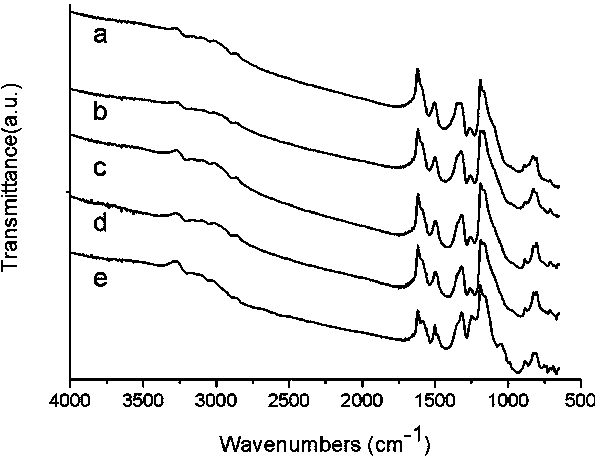

[0024] First, the graphene nanosheets were added into deionized water for ultrasonic dispersion for 30 minutes, and the concentration of the configuration was a uniformly dispersed graphene dispersion of 1 g / L; then aniline monomer and sulfuric acid were added to the graphene dispersion for ultrasonic dispersion for 30 minutes, wherein the aniline monomer and The mass ratio of graphene is 28:1, the concentration of sulfuric acid is 0.5mol / L, and the graphene / aniline mixed electrolyte solution is prepared; the flexible ITO conductive PET plastic substrate is selected as the working electrode, the platinum sheet electrode is used as the counter electrode, and the saturated calomel electrode As a reference electrode, place the three electrodes in the above-mentioned mixed electrolyte solution, and use the constant potential method to electrochemically polymerize at a voltage of 1.4V for 500 seconds and continue magnetic stirring to form a graphene / polyaniline composite film; take o...

Embodiment 2

[0027] First, add graphene nanosheets into deionized water for ultrasonic dispersion for 40 minutes, and configure a uniformly dispersed graphene dispersion with a concentration of 1.0 g / L; then add aniline monomer and sulfuric acid into the graphene dispersion for ultrasonic dispersion for 40 minutes, wherein the aniline monomer The mass ratio to graphene is 28:1, the concentration of sulfuric acid is 0.5mol / L, and the graphene / aniline mixed electrolyte solution is prepared; the flexible ITO conductive PET plastic substrate is selected as the working electrode, the platinum sheet electrode is used as the counter electrode, saturated calomel The electrode is used as a reference electrode, the three electrodes are placed in the above mixed electrolyte solution, and the constant potential method is used to electrochemically polymerize at a voltage of 1.6V for 500 seconds and continue magnetic stirring to form a graphene / polyaniline composite film; Take out the working electrode, ...

Embodiment 3

[0030]First, graphene nanosheets were added to deionized water for ultrasonic dispersion for 50 minutes, and the concentration of the configuration was a uniformly dispersed graphene dispersion of 1 g / L; then aniline monomer and sulfuric acid were added to the graphene dispersion for ultrasonic dispersion for 50 minutes, wherein the aniline monomer and The mass ratio of graphene is 28:1, the concentration of sulfuric acid is 0.5mol / L, and the graphene / aniline mixed electrolyte solution is prepared; the flexible ITO conductive PET plastic substrate is selected as the working electrode, the platinum sheet electrode is used as the counter electrode, and the saturated calomel electrode As a reference electrode, place the three electrodes in the above-mentioned mixed electrolyte solution, and use the constant potential method to electrochemically polymerize at a voltage of 1.8V for 500 seconds and continue magnetic stirring to form a graphene / polyaniline composite film; take out the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com