A kind of graphene electrothermal film

A graphene film and graphene technology, applied in electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of heating elements without automatic constant temperature and power compensation functions, short service life of electric heating elements, and complex structure of electric heating systems, etc. To achieve the effect of simple and effective design, rapid heat dissipation, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) 1 g of graphene oxide and 5 g of deionized water were mixed, and subjected to ultrasonic treatment at 50 KHz for 10 hours at 20° C. to obtain a graphene oxide solution.

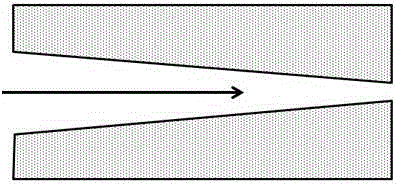

[0032] (2) Extrude the graphene oxide solution in a preparation device with a straight die at an extrusion speed of 10mL / h, stay in the n-butanol coagulation solution at 80°C for 1 second to solidify to form a film, and obtain the oxidized graphene membrane.

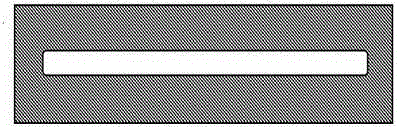

[0033] (3) The graphene oxide film obtained in step (2) is fully reduced in a 20% glucose aqueous solution, washed and dried to obtain a graphene film heating layer 2 . The thickness of the graphene film heating layer 2 is 0.5mm.

[0034] (4) Dissolve polyurethane in tetrahydrofuran (mass fraction is 20%), mix evenly and coat on the upper and lower sides of the graphene film heating layer 2 prepared in step 3, dry at 60°C and place on the top and bottom of the graphene film heating layer 2 An insulating protective layer 1 is formed on both ...

Embodiment 2

[0037] (1) 2 g of graphene, 50 g of N-methylpyrrolidone, and 100 g of pyridine were ultrasonically treated at 20° C. for 2 hours at 50 KHz to obtain a graphene solution.

[0038] (2) Extrude the graphene solution at a speed of 500mL / h in a preparation device with a straight die, stay in the ethyl acetate coagulation solution at 10°C for 20 seconds to solidify into a film, and obtain graphene after drying Film heating layer 2.

[0039] (3) Dissolve polyimide in tetrahydrofuran (mass fraction is 15%), mix evenly and coat on the upper and lower sides of the graphene film heating layer 2 prepared in step 3, dry at 60°C and place on the graphene film heating layer An insulating protective layer 1 is formed on the upper and lower sides of 2, and the thickness of the upper and lower insulating protective layers 1 is both 1 mm. Finally, a graphene electrothermal film is obtained.

[0040] Performance test: Connect two electrodes on the left and right sides of the graphene film heating...

Embodiment 3

[0042] (1) 1g of graphene oxide, 50g of N,N-dimethylformamide, 50g of N,N-dimethylacetamide, and 50g of tetrahydrofuran were ultrasonically treated at 20°C at 50KHz for 10 hours to obtain a graphene oxide solution.

[0043] (2) Extrude the graphene oxide solution in a preparation device with an inline die at an extrusion speed of 1000mL / h, and place it in a mixed solution of butyl acetate and n-propyl acetate at 60°C (volume ratio 1:1 ) for 1 second to solidify into a film, and obtain a graphene oxide film after drying.

[0044] (3) The graphene oxide film obtained in step (2) is fully reduced in an aqueous solution of vitamin C with a mass fraction of 50%, washed and dried to obtain a graphene film heating layer 2 . The thickness of the graphene film heating layer 2 is 0.5 mm.

[0045] (4) Dissolve ABS resin in tetrahydrofuran (mass fraction is 20%), mix evenly and coat on the upper and lower sides of the graphene film heating layer 2 prepared in step 3, dry at 60°C and plac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com