RFL treatment agent and application thereof

A treatment agent and latex technology, applied in the field of RFL treatment agent, can solve the problems of high viscosity of reinforced glass fiber rope, insufficient durability of timing belt, insufficient heat resistance of glass fiber rope, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

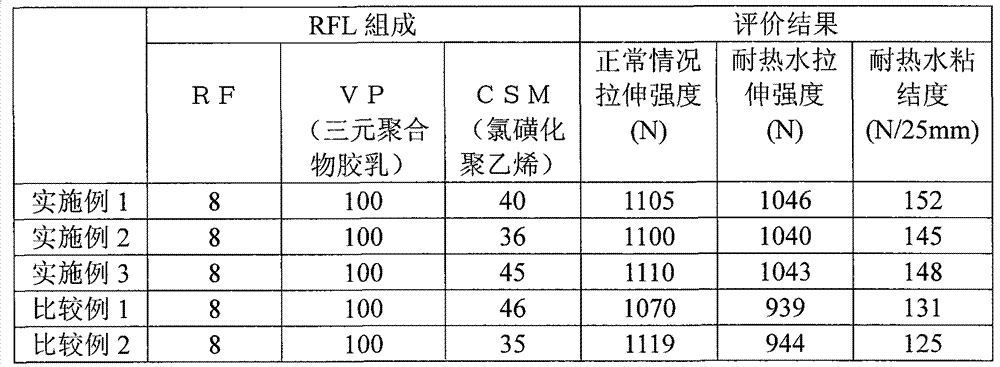

Embodiment 1

[0062] Concentration is the preparation of the RFL treating agent of 30%wt: with 100 parts of terpolymer latex (trade name [Pyratex], 40wt%, NIPPONA A&L company produces), 40 parts of chlorosulfonated polyethylene latex (trade name [CSM450], 40 wt%, manufactured by Sumitomo Seika Chemicals), 8 parts of RF condensate (manufactured by INDSPEC, 7 wt%) and deionized water were mixed. In addition, the above-mentioned parts of each component are parts by weight of solid content.

[0063] Concentration is the preparation of the OVC treating agent of 10wt%: 10 parts of chlorosulfonated polyethylene (trade name [Hypalon], manufactured by DuPont Co.), 5 parts of polyisocyanate (trade name [MR-200], manufactured by NIPPON POLYUERTHANE), p, 2 parts of p'-bibenzoylbenzoquinone dioxime is used as vulcanizing agent, 5 parts of carbon black is used as inorganic filler, and mixed together with toluene as solvent. The above parts are parts by weight of solid content.

[0064] Take 200 strands...

Embodiment 2

[0068] According to the process described in Example 1, the difference is that the RFL treatment agent of the following formula is used instead of the RFL treatment agent in Example 1 for preparation, and the glass fiber cord for rubber reinforcement of the present invention can be obtained.

[0069] The formula of described RFL treatment agent consists of: 100 parts of terpolymer latex (trade name "Pyratex", manufactured by NIPPONA & LINC.), 36 parts of chlorosulfonated polyethylene latex (trade name "CSM450", SUMITOMO SEIKA CHEMICAL CO.LTD), 8 parts of RF polycondensate (INDSPEC company, 7wt%) and deionized water were stirred to obtain a 30% concentration of the first treatment agent. The above-mentioned parts are parts by weight of solid content.

Embodiment 3

[0071] According to the process described in Example 1, the difference is that the RFL solution of the following formula is used instead of the RFL solution in Example 1 for preparation, and the glass fiber cord for rubber reinforcement of the present invention can be obtained.

[0072] The formula of described RFL treatment agent consists of: 100 parts of terpolymer latex (trade name "Pyratex", manufactured by NIPPONA & LINC.), 45 parts of chlorosulfonated polyethylene latex (trade name "CSM450", SUMITOMO SEIKA CHEMICAL CO.LTD), 8 parts of RF polycondensate (INDSPEC company, 7wt%) and deionized water were stirred to obtain a 30% concentration of the first treatment agent. The above-mentioned parts are parts by weight of the solid content of each component.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com