Heat-resistant waterproof hard paper and preparing method thereof

A steel paper, heat-resistant technology, applied in the field of papermaking, can solve the problems of improving heat and water resistance, achieve good interlayer peel strength and tensile strength, improve water absorption, and increase the effect of load rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

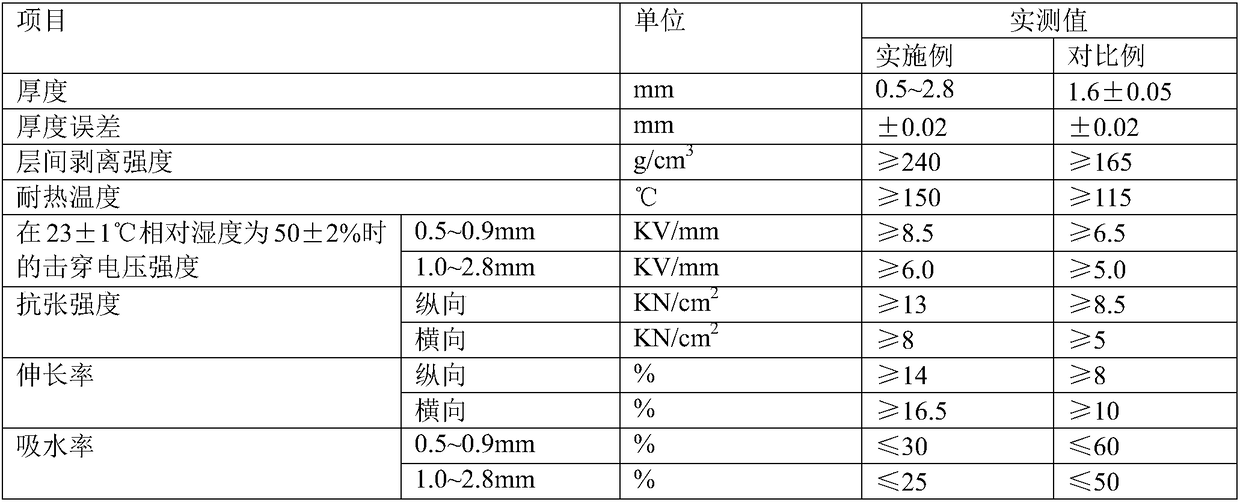

Examples

Embodiment 1

[0025] A heat-resistant and water-resistant steel paper, comprising the following components by weight: 130 parts of modified wood pulp with a solid content of 30 wt%, 25 parts of cotton pulp with a solid content of 30 wt%, 7 parts of modified kapok fiber, heat-resistant enhanced 15 parts of water-resistant enhancer, 7 parts of carboxymethyl cellulose, 9 parts of silica airgel, 350 parts of zinc chloride solution with a concentration of 12 wt%, modified trimethylolpropane triglycidyl ether 1.5 parts, 1.5 parts of sodium oleate.

[0026] The modified wood pulp is wood pulp modified by grafting trifluoromethyl trimethyl silane, and its preparation method is: adding hydrolyzed trifluoromethyl trimethyl silane to the wood pulp, mixing evenly, three The mass-volume ratio of fluoromethyltrimethylsilane to wood pulp is 2.5g / 50mL, fully reacted at 75°C for 24 hours under stirring conditions, to obtain trifluoromethyltrimethylsilane graft-modified wood pulp.

[0027] The modified trim...

Embodiment 2

[0037] A heat-resistant and water-resistant steel paper, comprising the following components by weight: 120 parts of modified wood pulp with a solid content of 35 wt%, 20 parts of cotton pulp with a solid content of 35 wt%, 6 parts of modified kapok fiber, heat-resistant enhanced 20 parts of water resistance enhancer, 6 parts of carboxymethyl cellulose, 8 parts of silica airgel, 400 parts of zinc chloride solution with a concentration of 8.4wt%, modified trimethylolpropane triglycidol 1 part of ether, 1 part of carboxylate.

[0038] The modified wood pulp is wood pulp grafted and modified by trifluoropropylmethylcyclotrisiloxane, and its preparation method is: adding hydrolyzed trifluoropropylmethylcyclotrisiloxane to the wood pulp, Mix evenly, the mass volume ratio of trifluoropropylmethylcyclotrisiloxane to wood pulp is 2g / 50mL, and fully react for 36h under the condition of stirring at 60°C to obtain trifluoropropylmethylcyclotrisiloxane grafted Modified wood pulp.

[003...

Embodiment 3

[0049] A heat-resistant and water-resistant steel paper, comprising the following components by weight: 120 parts of modified wood pulp with a solid content of 25 wt%, 20 parts of cotton pulp with a solid content of 25 wt%, 8 parts of modified kapok fiber, heat-resistant enhanced 10 parts of water-resistant enhancer, 8 parts of carboxymethyl cellulose, 10 parts of silica airgel, 300 parts of zinc chloride solution with a concentration of 20 wt%, modified trimethylolpropane triglycidyl ether 2 parts, 2 parts of sulfonate.

[0050] The modified wood pulp is wood pulp modified by grafting tridecafluorooctyltrimethoxysilane, and the preparation method is as follows: adding hydrolyzed tridecafluorooctyltrimethoxysilane into the wood pulp, mixing evenly, and The mass-volume ratio of trifluorooctyltrimethoxysilane to wood pulp is 3g / 50mL, and fully reacted at 85°C for 12h under stirring conditions to obtain trifluorooctyltrimethoxysilane graft-modified wood pulp.

[0051] The modifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com