Concentric type integrated test modification water injection technology and device

A concentric, technological technology, applied in the directions of measurement, production of fluid, wellbore/well components, etc., can solve the problems of low injection efficiency, low success rate, labor-intensive and other problems, and achieve the effect of convenient maintenance and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

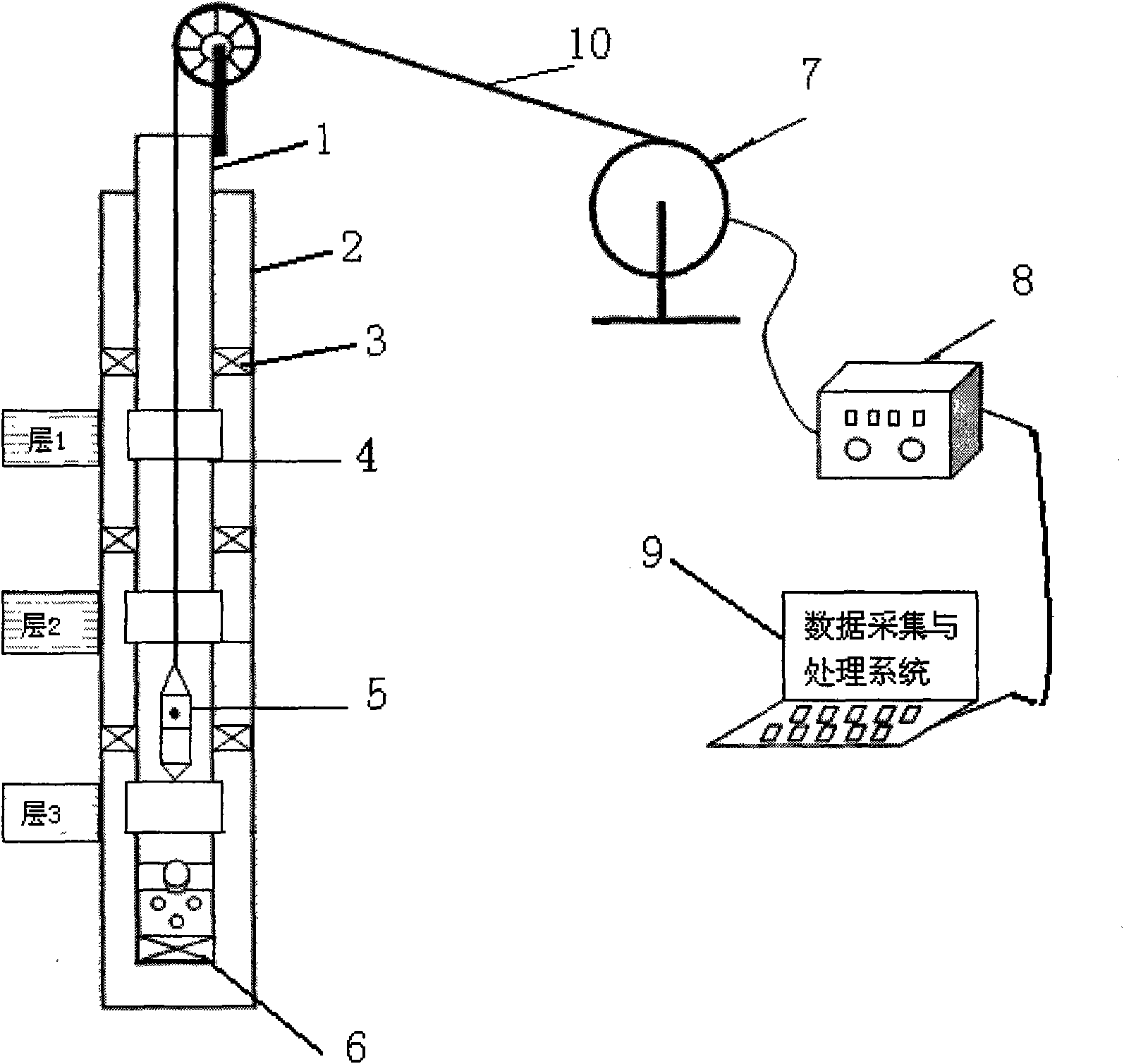

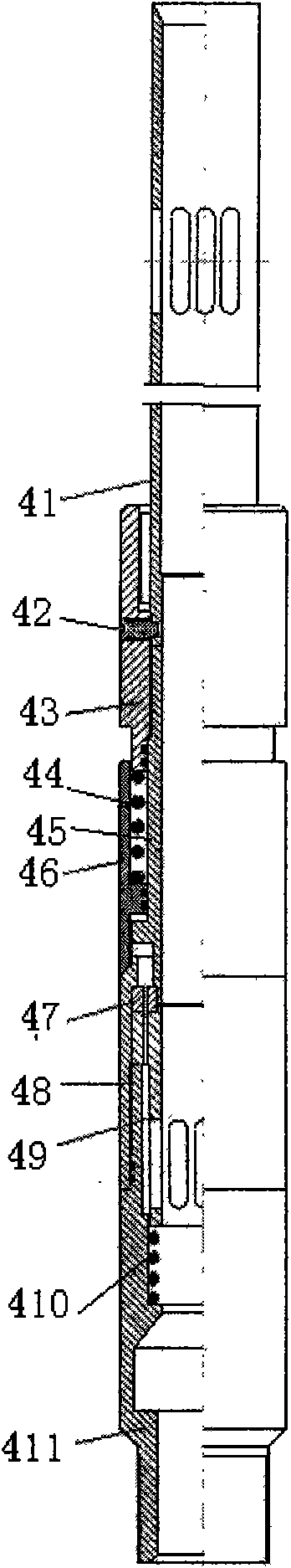

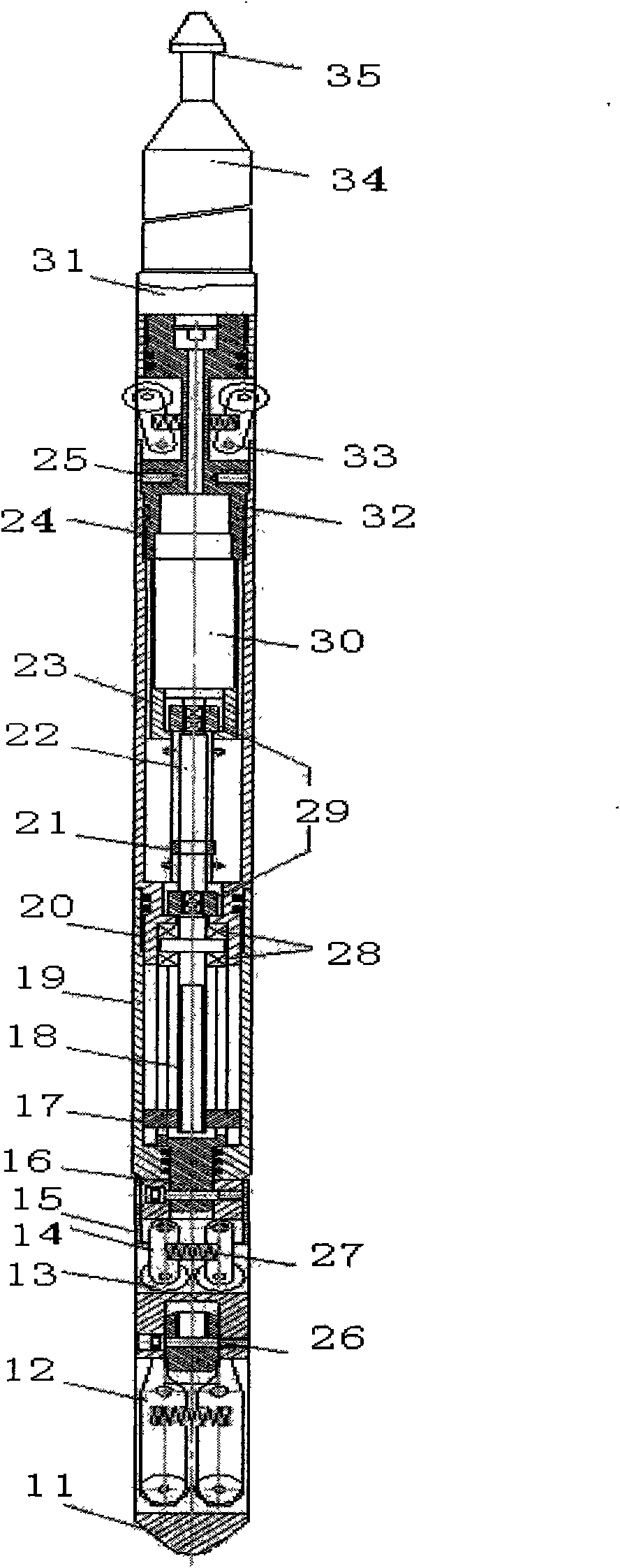

[0017] A concentric integrated measurement and adjustment water injection process, including the following sequential steps: (A) running a concentric integrated measurement and adjustment water injection process string; (B) installing a wellhead blowout preventer; (C) opening the water injection process for normal water injection, It is characterized in that it also includes (D) lowering the integrated measuring and adjusting instrument to the plug at the bottom of the water injection string; (E) lifting the integrated measuring and adjusting instrument to locate the water distribution device at the lowest level; (F) The ground control system starts the integrated measuring and adjusting instrument, and transmits the collected and stored temperature, pressure and flow data of the downhole water injection layer to the ground data acquisition and processing system, and displays them in real time; (G) the integrated measuring and adjusting instrument Adjust the size of the nozzle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com