Highway deceleration strip generating set

A technology for power generation devices and speed bumps, which is applied to machines/engines, mechanical equipment, mechanisms for generating mechanical power, etc., can solve the problems of increasing the production cost of speed bumps, high costs, and constraints, and achieve improved energy utilization and connection methods Unique, Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

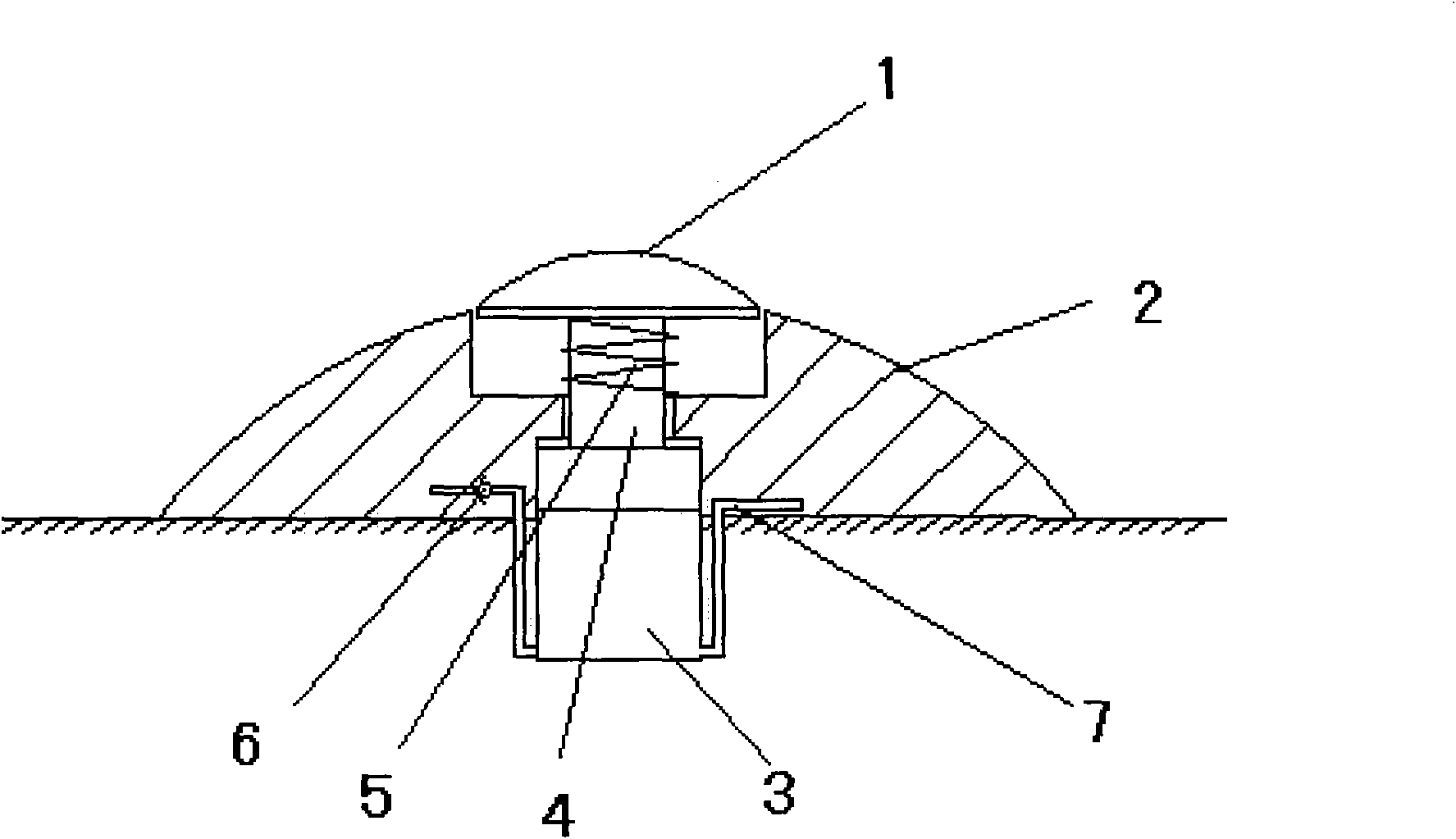

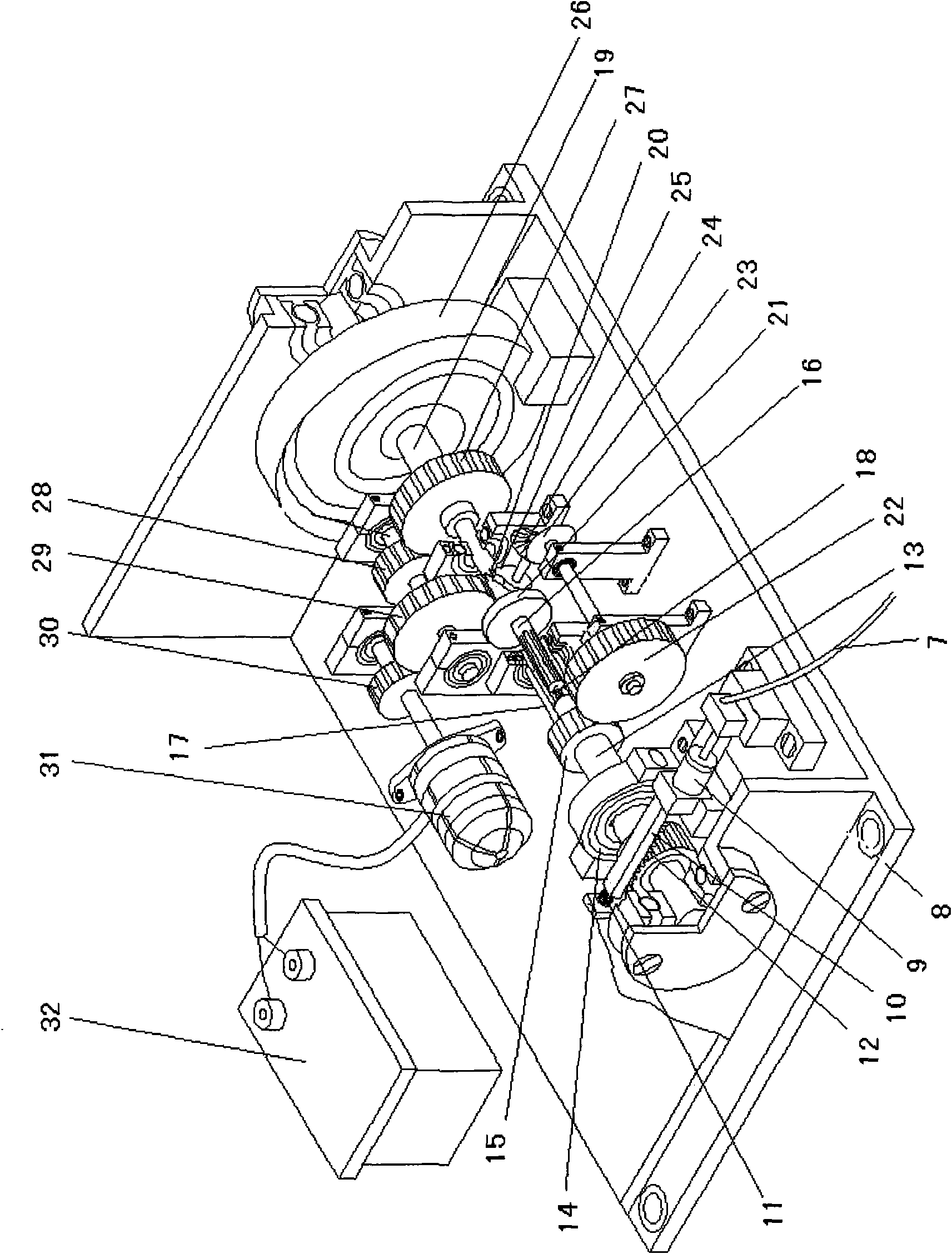

[0019] The present invention consists of figure 1 The pavement section shown and as figure 2 The host section shown consists of two parts.

[0020] The function of the road surface is to convert the mechanical energy of the car into compressed air and transmit it to the host part. The road surface part is mainly composed of a pressure body 1, a deceleration belt 2 and a cylinder group. The cylinder group includes a cylinder 3, a piston 4, a return spring 5, an air intake pipeline 6 and an air outlet pipeline 7, etc. Its specific structure is as follows: figure 1 Shown:

[0021] There is a groove on the upper surface of the speed bump 2, and the cylinder group is embedded in the speed bump 2, wherein the upper end of the piston 4 protrudes from the cylinder 3 and is exposed in the groove. The top of the piston 4 is connected with a pressure body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com