Laser interference system used for measuring micro roll angle

一种激光干涉、光干涉的技术,应用在激光干涉系统领域,能够解决测量精度影响、不易实时测量、需要参考镜等问题,达到系统稳定、结构简单、分辨率高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The purpose of the present invention will be described in detail below with reference to the accompanying drawings.

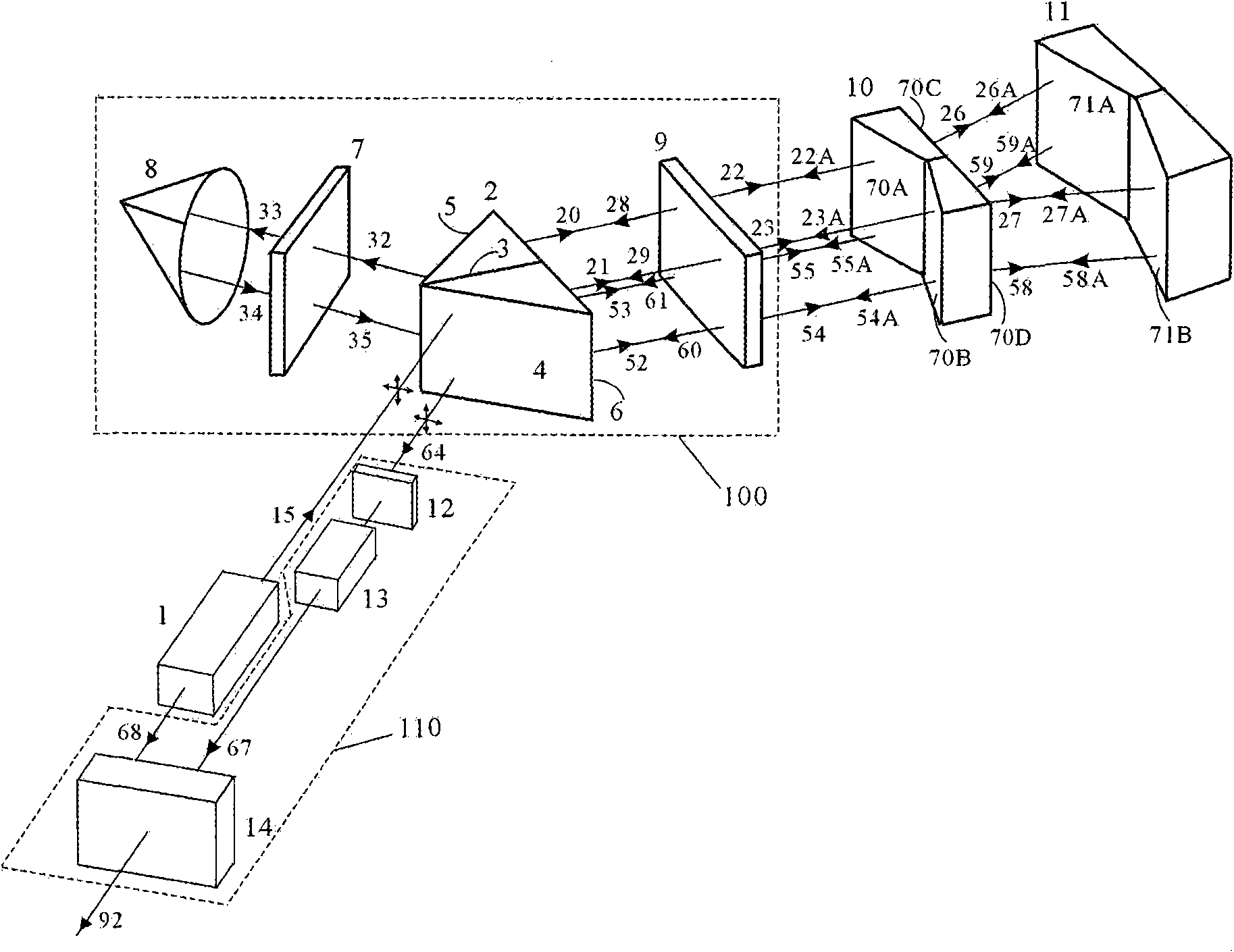

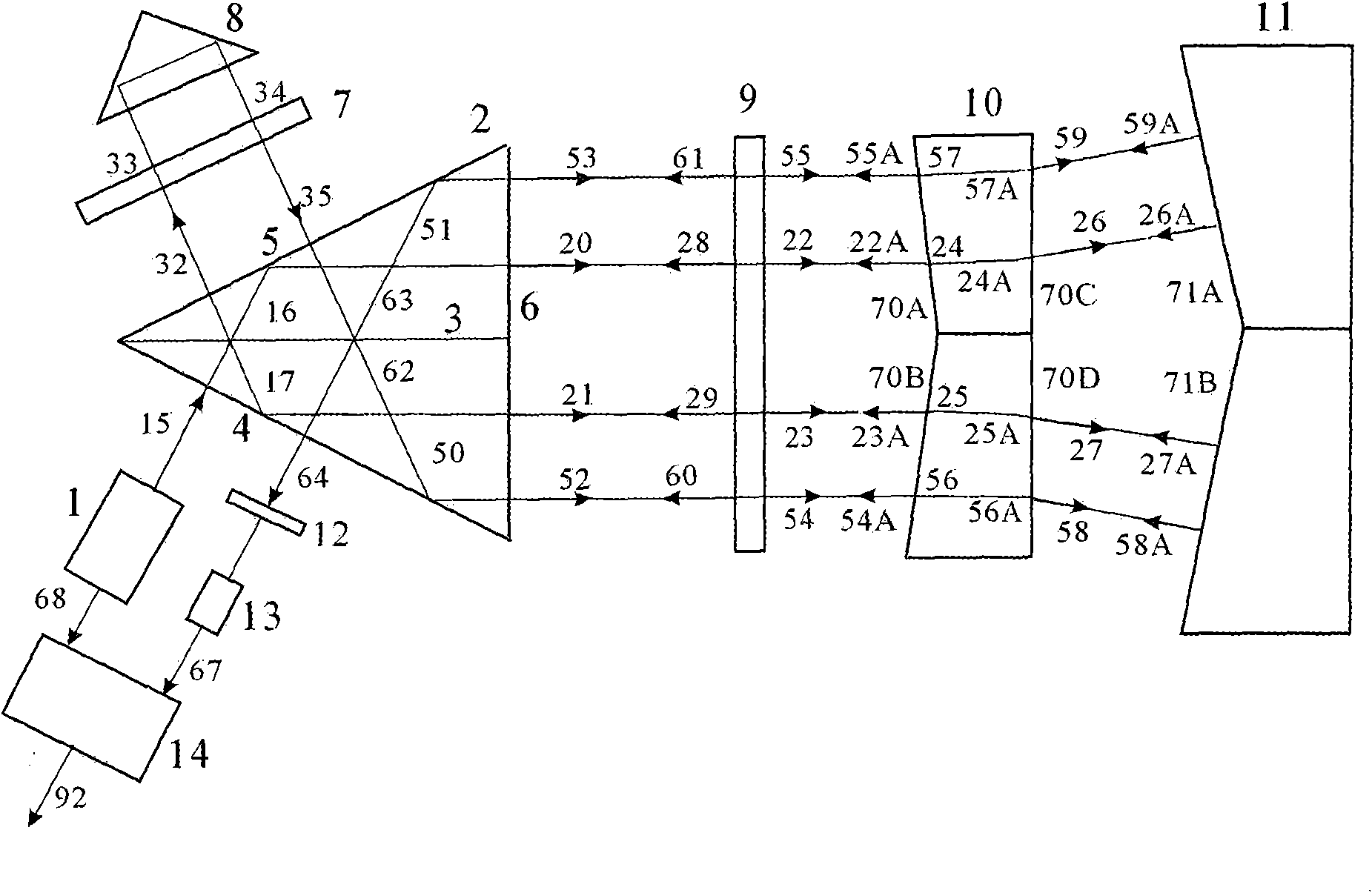

[0036] figure 1 It is a structural diagram of a laser interference system according to a preferred embodiment of the present invention, including a laser source 1 , an optical interference device 100 , a wedge prism 10 , a light reflection device 11 , and a phase detection device 110 .

[0037] The optical interference device 100 includes a dichroic prism 2 , a quarter wave plate 9 , a quarter wave plate 7 , and a corner cube 8 . The phase detection device includes a polarizer 12 , a photodetector 13 and a phase meter 14 .

[0038] The laser source 1 adopts a dual-frequency laser. On the one hand, the laser source 1 provides a frequency-stabilized incident beam to the beam splitter 2. The beam contains two components with different frequencies and linear polarization directions that are orthogonal to each other. At the same time, it also provides a phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com