Method for installing temperature probe of conduction cooling superconducting magnet

A technology of superconducting magnets and temperature probes, applied to thermometers, parts of thermometers, measuring devices, etc., to achieve the effect of ensuring tightness and easy installation

Inactive Publication Date: 2011-01-05

INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to overcome the problem of temperature probe installation in key parts of the conduction cooling superconducting magnet system, and propose a new temperature probe installation method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

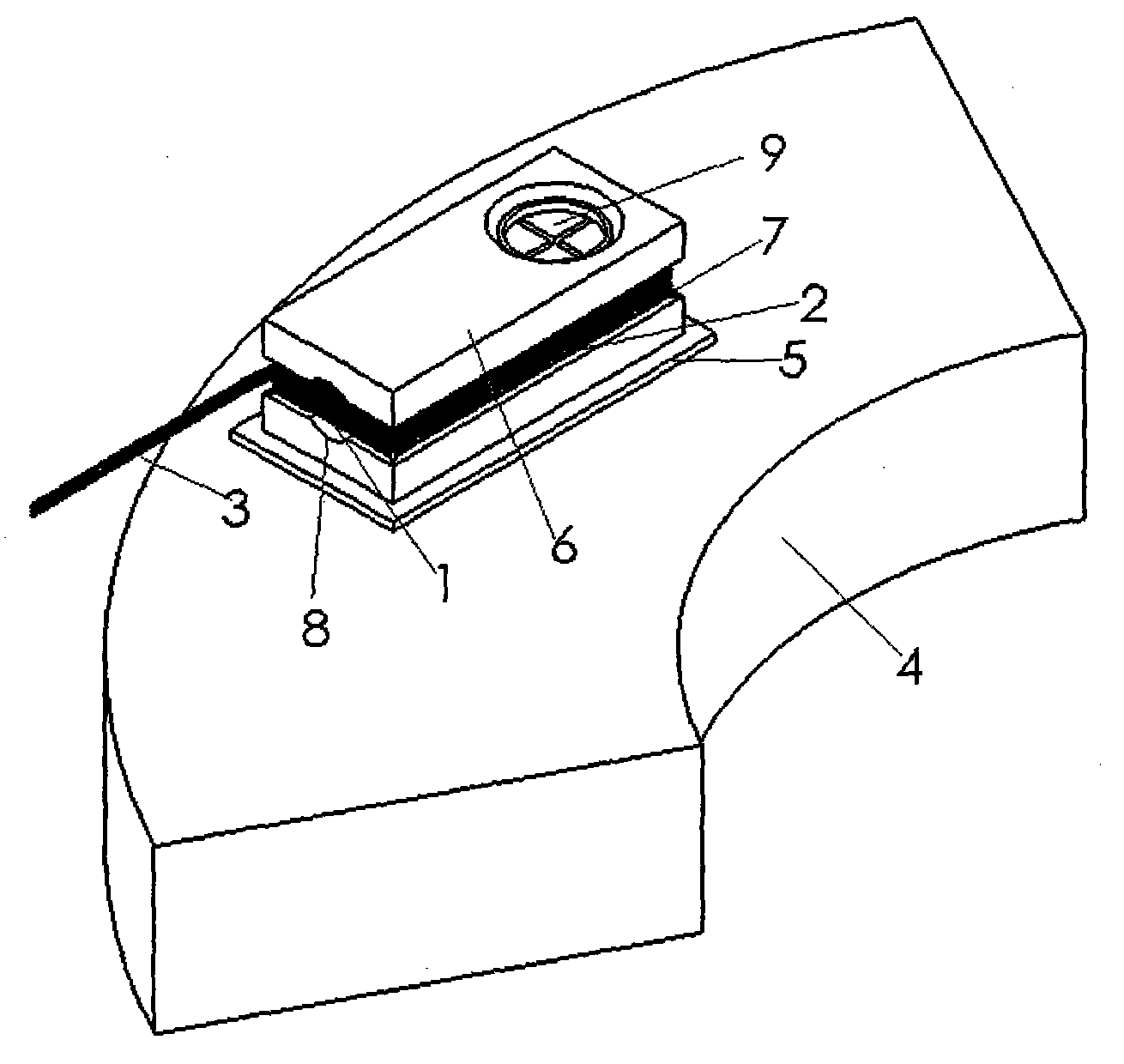

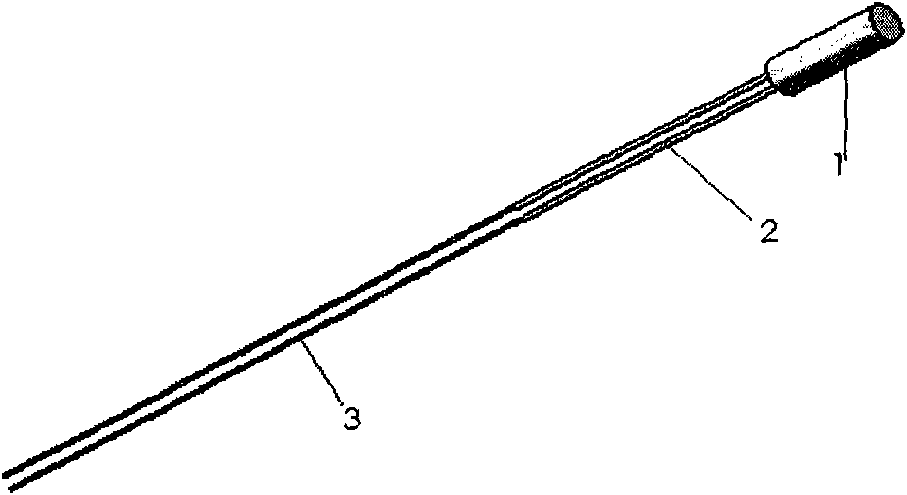

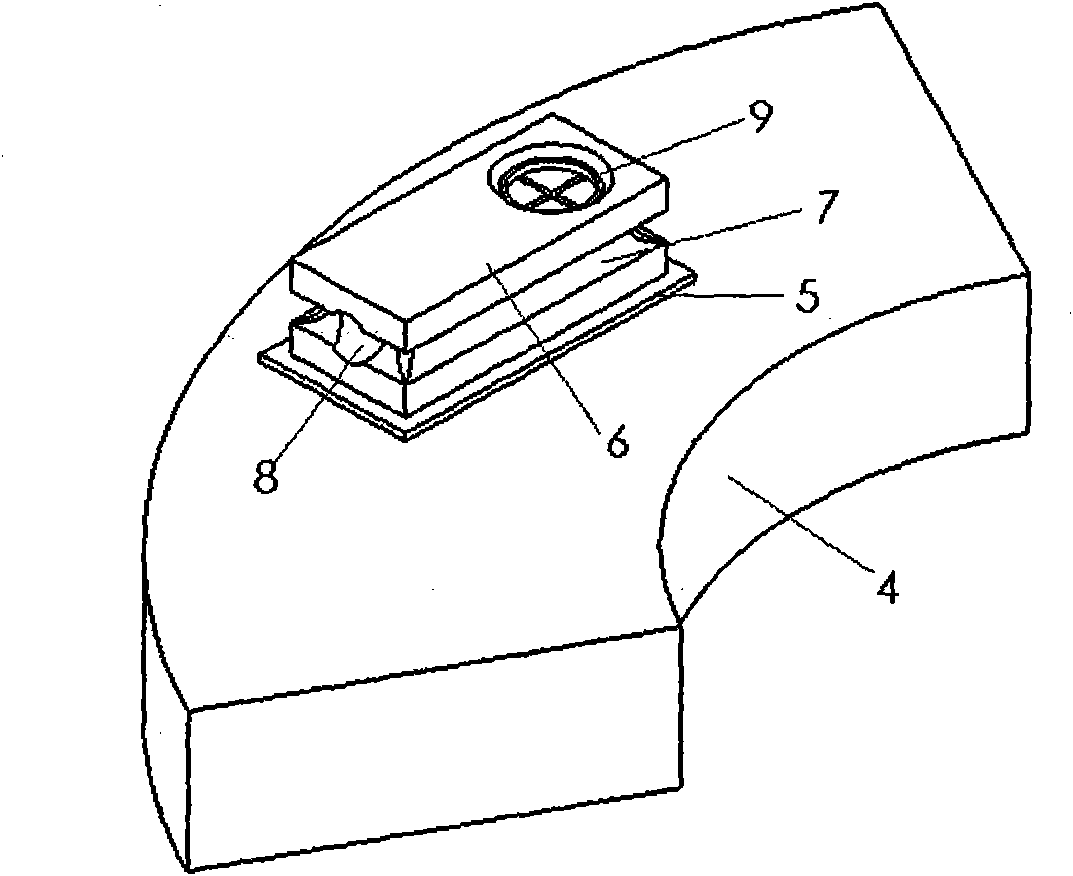

The invention relates to a method for installing a temperature probe of a conduction cooling superconducting magnet, which is characterized in that firstly, a length of thin copper wire (2) with an insulation layer is welded on a lead-out wire of a temperature probe (1), and then a length of thin manganin wire (3) with an insulation layer is welded and is connected with the thin copper wire; the thin manganin wire (3) is connected to the outside of a superconducting magnet; the temperature probe (1) is arranged in a round hole (8) of the front of a heat sink (6) of a cuboid made of a high-purity copper material; gaps between the temperature probe (1) and the wall of the round hole (8) are filled with high-thermal conductivity silicone grease; the heat sink (6) is arranged at a detected position of the superconducting magnet; an indium foil sheet is adhered between the bottom surface of the heat sink (6) and the surface of the detected position of the superconducting magnet, and a boltis utilized to tightly press the heat sink (6) on the surface of the detected position (4) of the superconducting magnet; the thin copper wire (2) is wrapped in semicircle grooves (7) around the heatsink (6), and gaps between the thin copper wires (2) are filled with the silicone grease.

Description

A method for installing a conduction cooling superconducting magnet temperature probe technical field The invention relates to an installation method of a temperature probe used for temperature measurement of key parts of a conduction cooling superconducting magnet. Background technique In the late 1990s, the technology of conduction-cooled superconducting magnets developed rapidly, gradually replacing liquid helium-immersed superconducting magnets. Compared with the traditional liquid helium soaked superconducting magnet system, the conduction cooling superconducting magnet does not use liquid helium to cool, but uses a two-stage G-M refrigerator as a cold source to cool the superconducting magnet. Since the entire superconducting magnet is cooled by a single cold source by heat conduction, the connection between the various parts of the superconducting magnet must be tight, and the heat conduction must be very good, and the secondary cold head of the refrigerator has onl...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01K1/14

Inventor 陈顺中王秋良雷沅忠

Owner INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com