Thin film transistor array substrate and LCD

A technology of thin-film transistors and array substrates, which is applied in the field of liquid crystal display devices and thin-film transistor array substrates, and can solve problems such as greatly affecting display quality and product performance, and reducing display brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0020] Please refer to image 3, which shows a side view of a liquid crystal display device according to the first embodiment of the present invention. The liquid crystal display device 100 of this embodiment includes a thin film transistor array substrate 40 , an opposite substrate 20 , spacers 10 and a liquid crystal layer 30 . The spacer 10 is arranged on the surface of the opposite substrate 20 facing the thin film transistor array substrate 40, and contacts the thin film transistor array substrate 40, so that there is a fixed distance between the thin film transistor array substrate 40 and the opposite substrate 20, and the liquid crystal layer 30 Filled and distributed between the opposite substrate 20 and the thin film transistor array substrate 40 , the spacers 10 are preferably photosensitive resin and formed by photolithography.

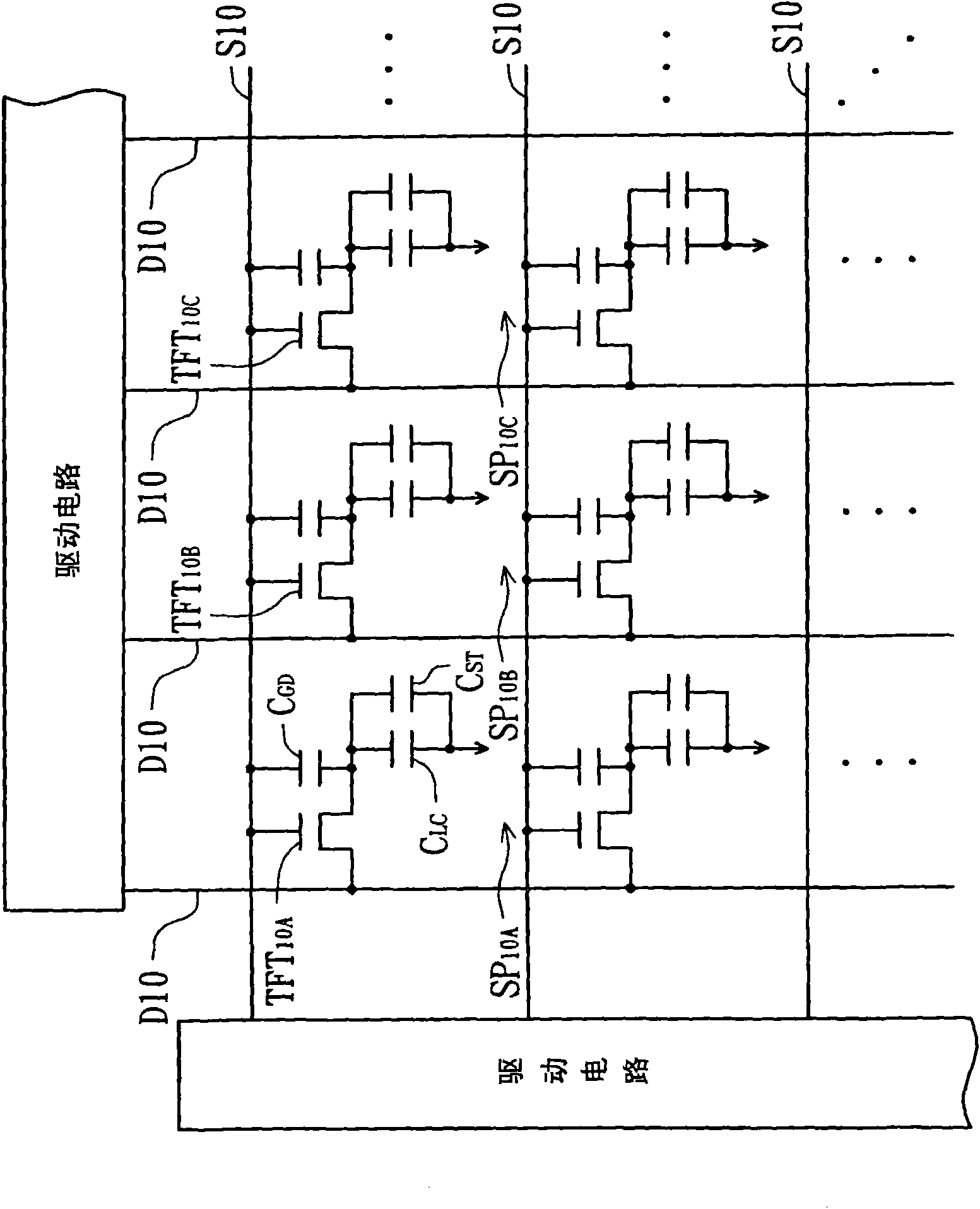

[0021] Figure 4 A top view of the thin film transistor array substrate 40 according to the first embodiment of the present invention is...

no. 2 example

[0036] The difference between this embodiment and the above-mentioned embodiments lies in the technical means adopted for uniform feed-through voltage, especially in the case of not changing the storage capacitive coupling area, only by changing the shape of the capacitor electrode to achieve uniform feed-through voltage and At the same time, the purpose of providing a space for the spacer is provided. Figure 6 A top view of a thin film transistor array substrate according to a second embodiment of the present invention is shown.

[0037] Please refer to Figure 6 The plurality of capacitor electrodes at least include a first capacitor electrode 44a, a second capacitor electrode 44b, and a third capacitor electrode 144c respectively located on the first conductive portion 42a, the second conductive portion 42b, and the third conductive portion 42c. The capacitor electrode 44a , 44b, 44c are coupled with conductive parts 42a, 42b, 42c to form a plurality of pixel storage capa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com