Method for realizing PLC port control by C language in digital control machine tool system

A CNC machine tool and port control technology, applied in digital control, electrical program control, etc., can solve the problems of difficult writing of PLC programs and difficult understanding of PLC language, and achieve the effects of wide application range, simple and convenient processing process, stable and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

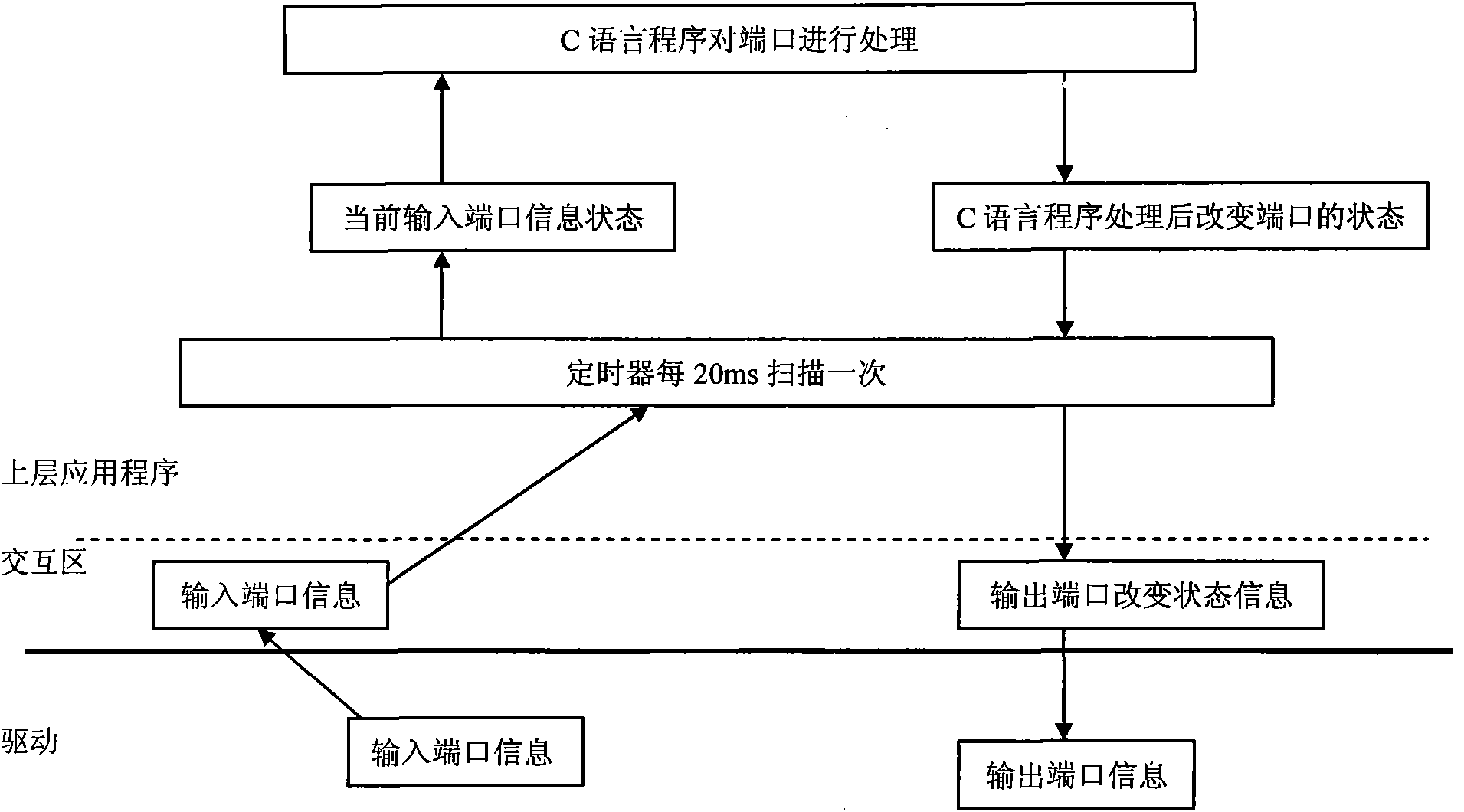

[0019] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings.

[0020] See figure 1

[0021] 1. Obtain port information and port address information in the timer

[0022] To use the C language to control the port, we must first obtain the information of the port. Our timer has a high accuracy, scanning every 20 milliseconds to obtain the current port status.

[0023] How to get the port address:

[0024] 11. Addressing method of physical port:

[0025] The physical ports are divided into input ports and output ports. They are addressed in channel mode, each channel has 32 numbers, that is, each channel can accommodate 32 ports. Among them, 100 channels are divided into input ports and output ports, which means that the system can accommodate 3200 physical input ports and 3200 physical output ports. The port addre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com