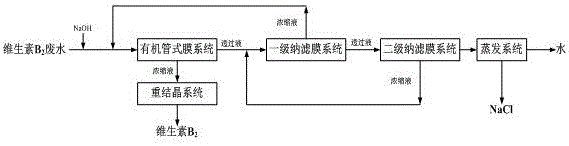

Zero discharging method and device for vitamin B2 production waste water

A vitamin, zero-emission technology, applied in chemical instruments and methods, water pollutants, multi-stage water treatment, etc., can solve problems such as high salt content, waste of resources, recycling, etc., achieve environmental protection and economic benefits, and solve difficult problems. Processing, technologically advanced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

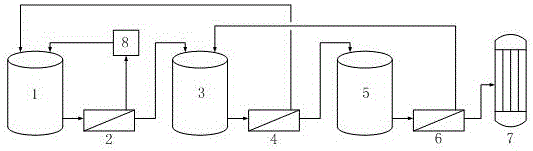

Method used

Image

Examples

Embodiment 1

[0032] S1: Vitamin B in acidic wastewater (pH about 1 to 3) from the production section 2 The concentration is 1.20g / L, adjust the pH to 6 with liquid caustic soda first, mix with the first-stage nanofiltration membrane retentate returned in the later stage, and then vitamin B 2 The concentration is 1.25g / L, and then sent to the organic tubular membrane system, the pore size of the organic tubular membrane is 30nm, the control operating pressure is 0.3MPa, and the average flux of the membrane is 102L / m 2 h, vitamin B 2 The crystals are retained, and vitamin B in the retained concentrate 2 The concentration is 32.5g / L, the concentrated solution meets the requirements of recrystallization, and vitamin B is obtained through recrystallization 2 Product, product purity is 99.76%, vitamin B in permeate 2 Concentration 560mg / L;

[0033] S2: The permeate of the organic tubular membrane system is sent to the first-stage nanofiltration system for separation. The molecular weight cut...

Embodiment 2

[0036] S1: Vitamin B in acidic wastewater (pH about 1 to 3) from the production section 2 The concentration is 3.21g / L, adjust the pH to 7 with liquid caustic soda first, mix with the first-stage nanofiltration membrane retentate returned in the later stage, and then vitamin B 2 The concentration is 3.23g / L, and then sent to the organic tubular membrane system, the organic tubular membrane pore size is 50nm, the control operating pressure is 0.55MPa, and the average flux of the membrane is 86L / m 2 h, vitamin B 2 The crystals are retained, and vitamin B in the retained concentrate 2 The concentration is 41.6g / L, the concentrated solution meets the requirements of recrystallization, and vitamin B is obtained through recrystallization 2 Product, product purity is 99.85%, vitamin B in permeate 2 Concentration 756mg / L;

[0037] S2: The permeate of the organic tubular membrane system is sent to the first-stage nanofiltration system for separation. The molecular weight cut-off of...

Embodiment 3

[0040] S1: Vitamin B in acidic wastewater (pH about 1 to 3) from the production section 2 The concentration is 1.89g / L, adjust the pH to 5 with liquid caustic soda first, mix with the first-stage nanofiltration membrane retentate returned in the later stage, and then vitamin B 2 The concentration is 1.93g / L, and then sent to the organic tubular membrane system, the pore size of the organic tubular membrane is 30nm, the control operating pressure is 0.4MPa, and the average flux of the membrane is 98L / m 2 h, vitamin B 2 The crystals are retained, and vitamin B in the retained concentrate 2 The concentration is 35.4g / L, the concentrated solution meets the requirements of recrystallization, and vitamin B is obtained through recrystallization 2 Product, product purity is 99.85%, vitamin B in permeate 2 Concentration 632mg / L;

[0041] S2: The permeate of the organic tubular membrane system is sent to the first-stage nanofiltration system for separation. The molecular weight cut-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com