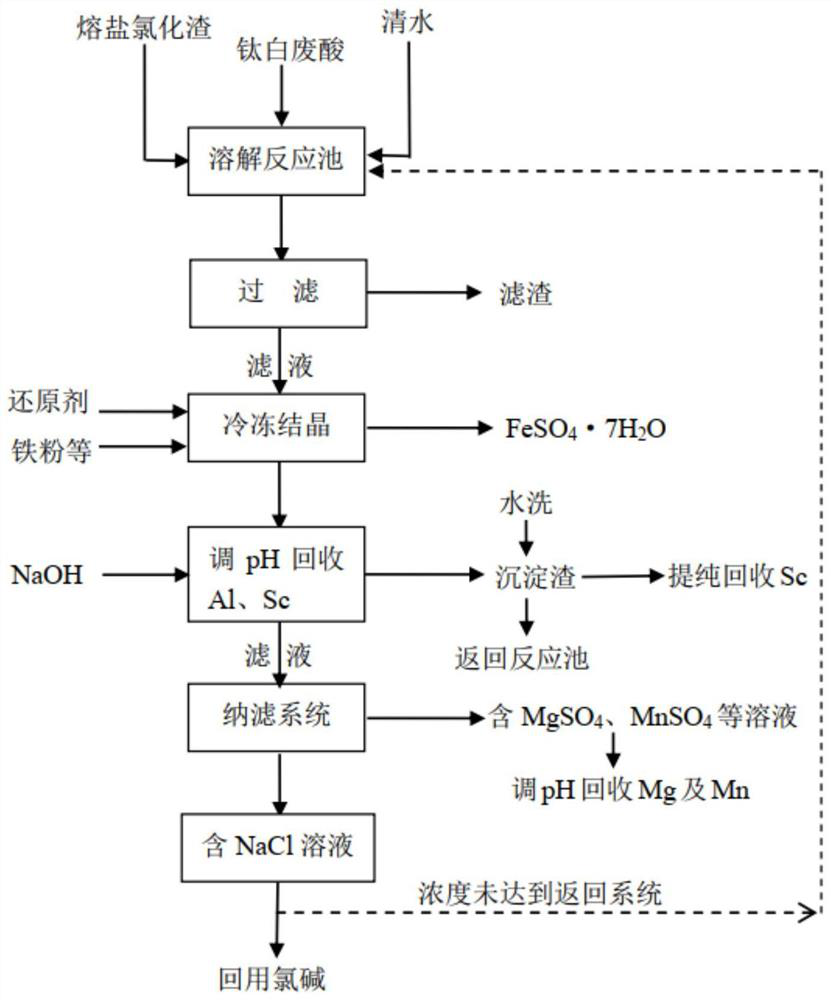

Resource utilization method of titanium dioxide waste acid leaching fused salt chlorination slag

A technology of molten salt chlorination slag and titanium white waste acid, which is applied in the fields of alkali metal halide purification, titanium oxide/hydroxide, aluminum oxide/aluminum hydroxide, etc., to achieve difficult-to-handle, simple process, and easy implementation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Take 1000g of molten salt chlorination slag, use water: molten salt chlorination slag (composition as shown in Table 1) mass ratio of 3:1 to carry out water quenching, continue to use titanium dioxide waste acid (composition as in Table 2): molten salt chlorination The residue mass ratio is 1:1, fully dissolved under stirring, filtered and separated to obtain about 710.8g of filter residue 1, and its composition is shown in Table 3, TiO 2 Into the slag phase up to 93%, SiO 2 91.8% of Ca enters into the slag phase, and about 80% of Ca enters into the slag phase. After washing with water, it is used as raw material for titanium extraction by chloride.

[0038] Add appropriate amount of Fe powder (3.2g) to 2905mL of the supernatant obtained through the above filtration, and add an appropriate amount of Fe powder (3.2g) under stirring. After dissolving, quickly put it into a high-low temperature box to cool down to 10°C, and crystallize a relatively transparent FeSO 4 Crys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com