Electric furnace continuous casting short process production method of oil well pipe billets

A short process, oil well pipe technology, applied in the field of iron and steel smelting, can solve the problems of oil well pipe billet steel technology integration, incomplete application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

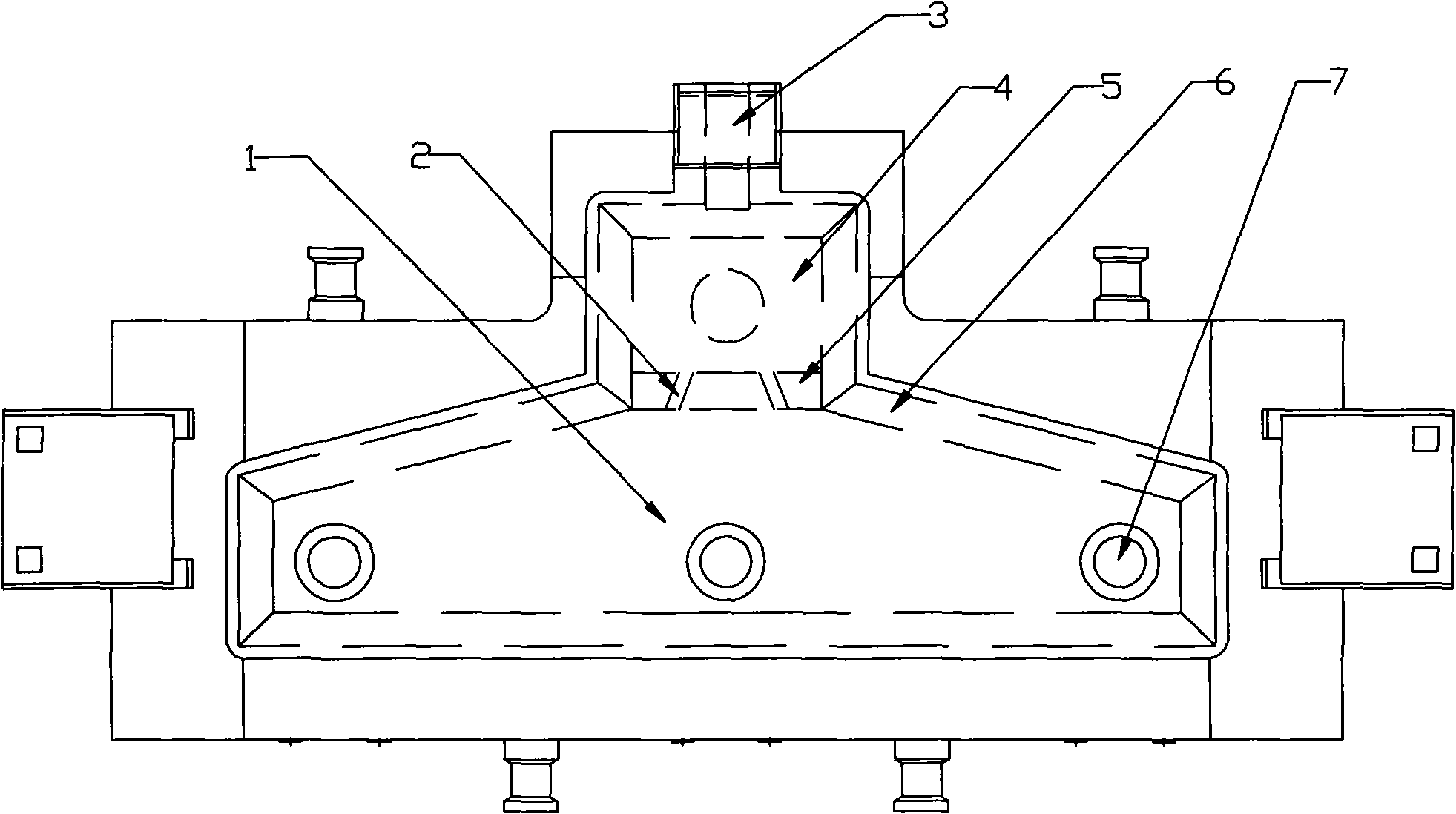

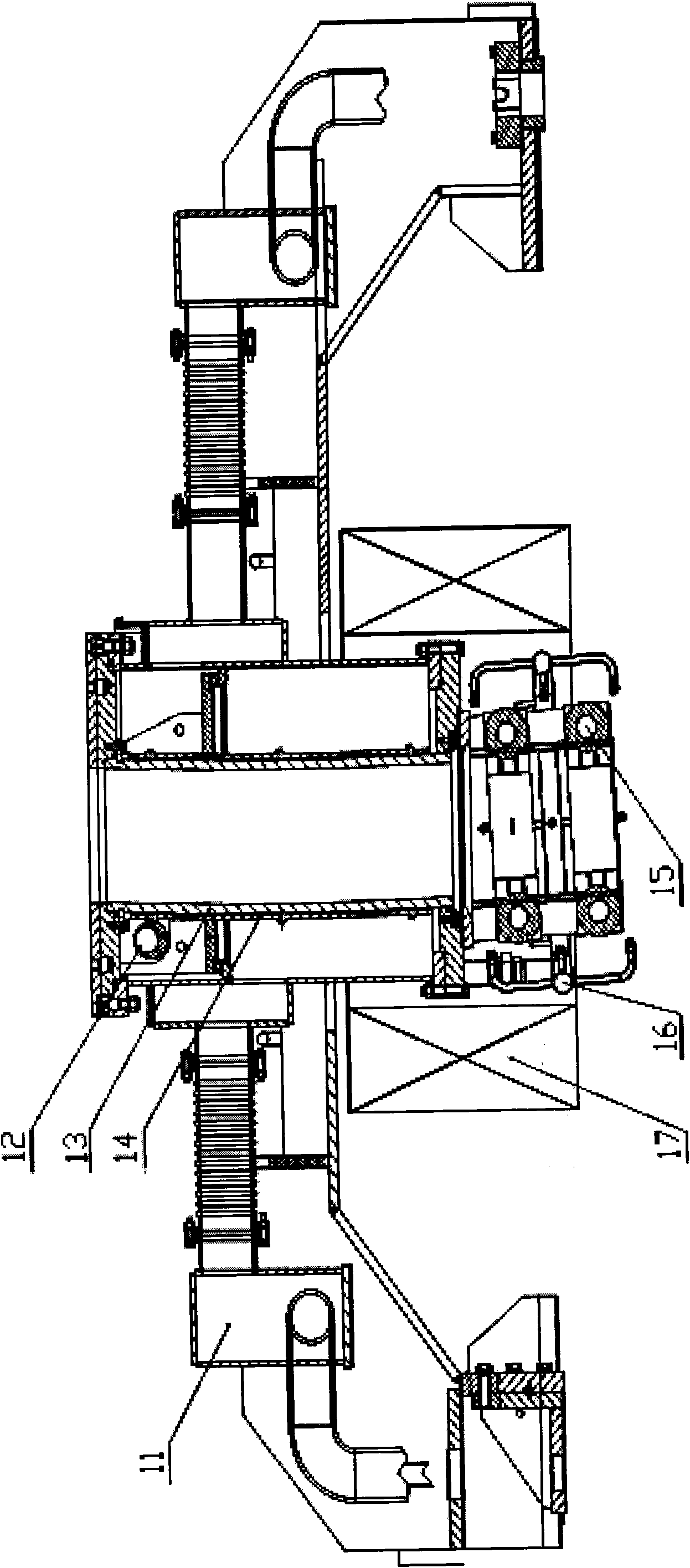

[0035] The invention discloses a short-flow electric furnace continuous casting method for producing oil well pipe billet steel, which includes electric arc furnace smelting, LF refining outside the furnace, VD vacuum treatment, and full-protection pouring continuous casting round pipe billet. It is characterized in that the entire pouring process from the ladle to the tundish and from the tundish to the mold is sealed and protected without oxidation; the secondary cooling adopts a dynamic gas-mist cooling method; When the billet and round billet are produced alternately, only the crystallizer assembly and the nozzles of the first stage of secondary cooling, the second stage of secondary cooling and the third stage of secondary cooling are replaced. The main body of the dummy rod does not move, and only the head rod is replaced. The taper of the copper tube of the mold in the mold assembly is parabolic, which ensures good contact between the billet shell and the copper tube, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com