Cam type centering clamping chuck

A clamping chuck and cam type technology, applied in the field of mechanical processing, can solve the problems of low centering accuracy, high manufacturing cost, limited clamping force, etc., and achieve the effect of simple structure of parts, low cost and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

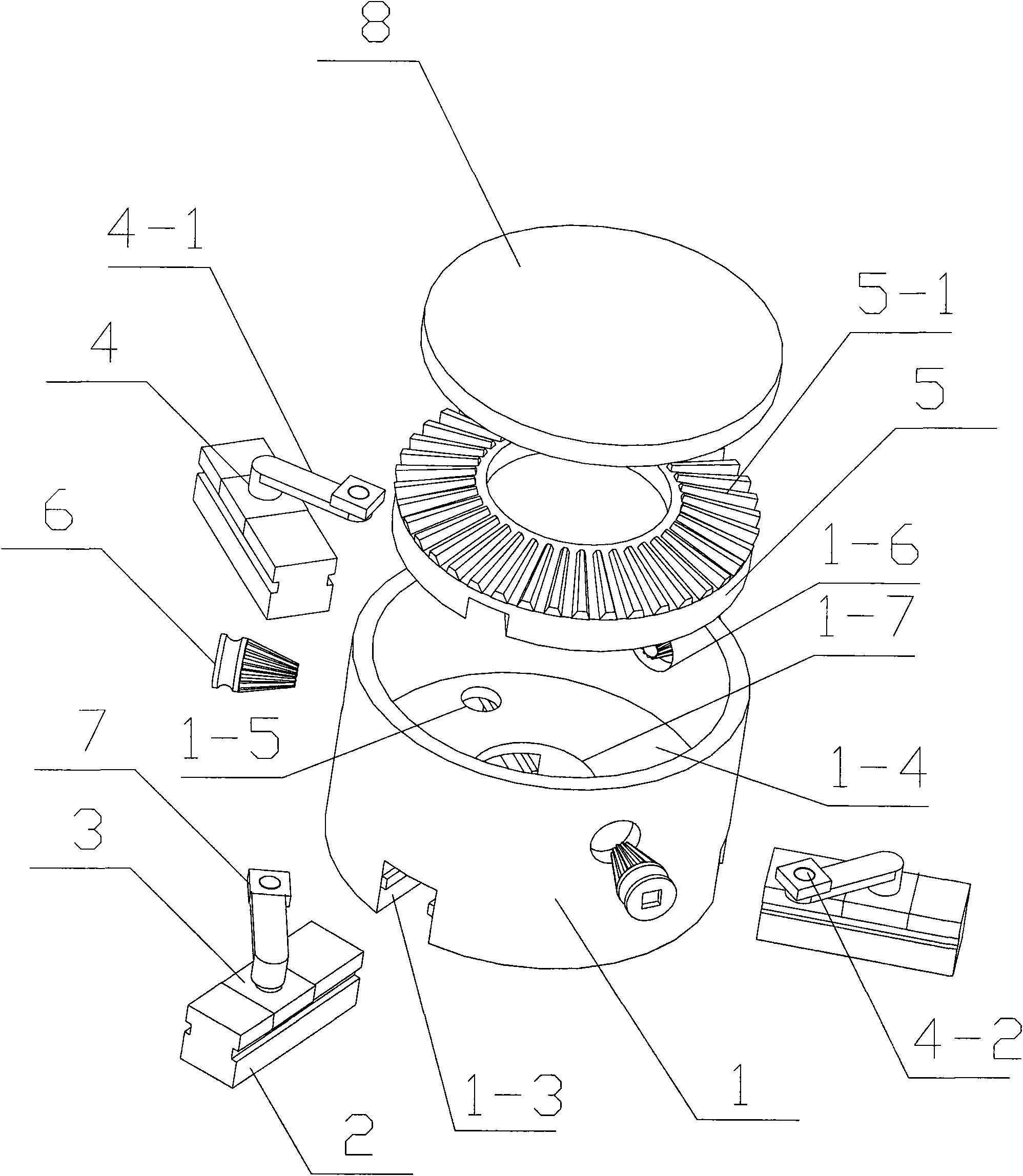

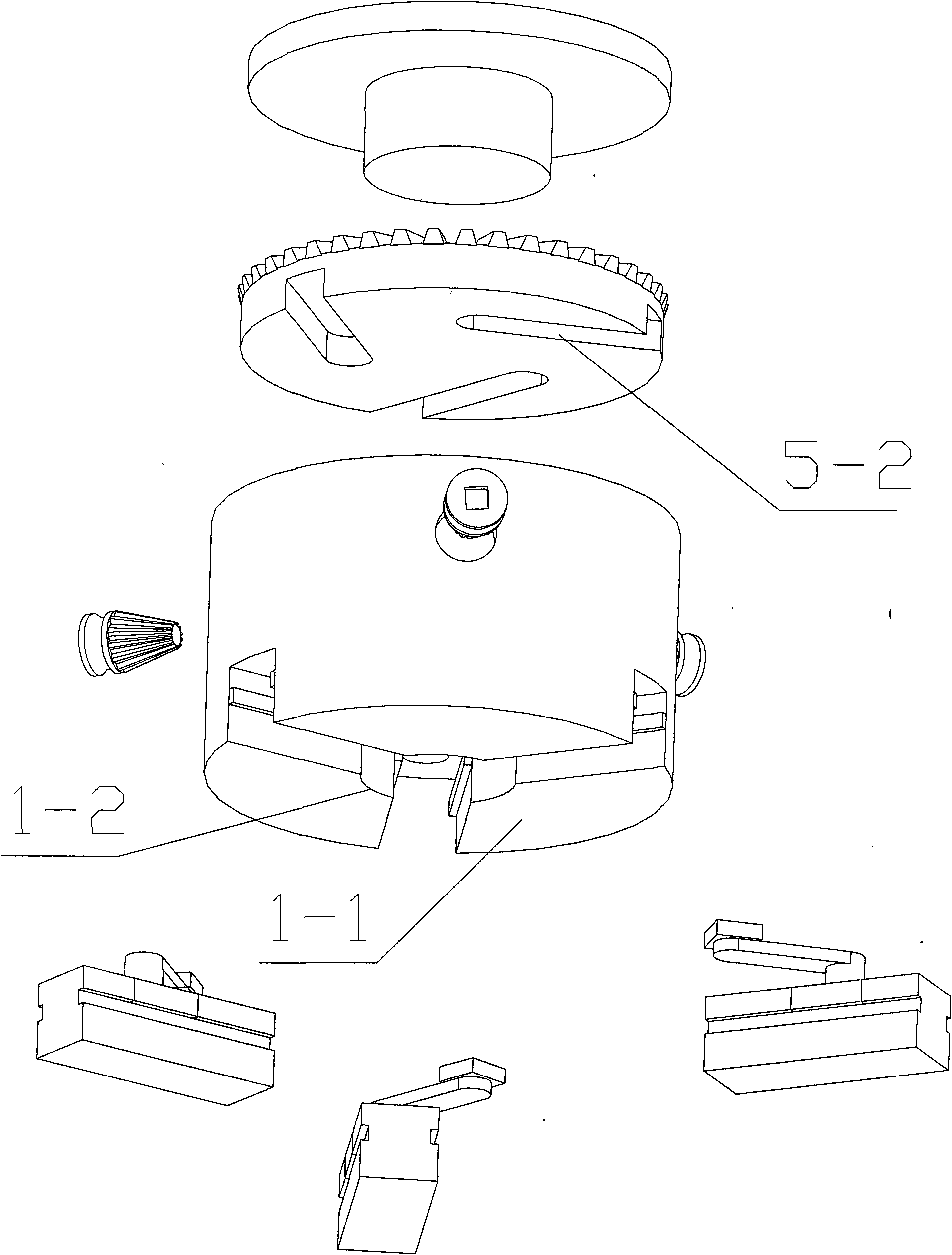

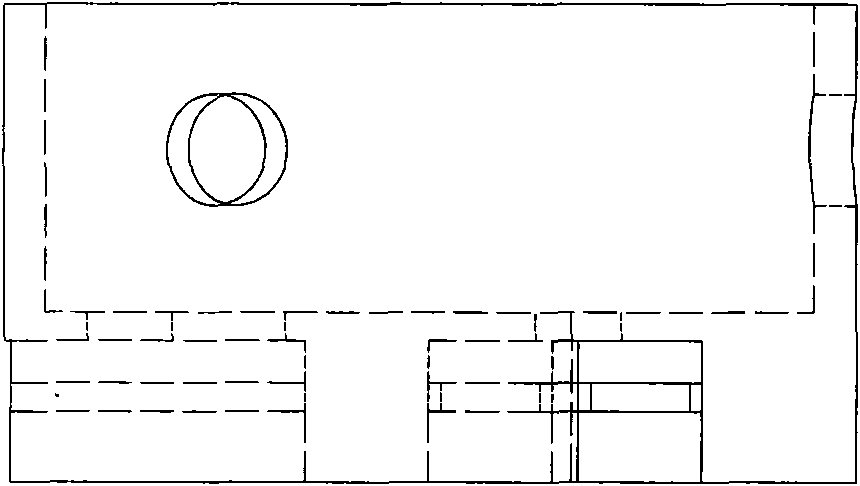

[0029] Cam-type centering clamping chuck, including the chuck body 1, and also includes three jaws 2, three square sliders 3, three eccentric cams 4, three clamping blocks 7, toothed disc 5 and three small cones Gear 6; disc body 1 is a cylindrical groove body, and its base plate 1-1 is provided with a central hole 1-2, and base plate 1-1 is provided with three equally divided radial chute 1-3; chuck body 1 is provided with A partition 1-4 is provided with three equally divided partition through holes 1-5 and a partition center hole 1-7, and the upper wall of the chuck body 1 is provided with three wall holes 1-6 equally divided along the circumference The claw 2 cooperates with the chute 1-3, the inner end surface of the claw 2 is provided with a square slot, the square slider 3 is embedded in it, and the square slider 3 is provided with a slider hole;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com