Crack resistance type cement stabilized macadam proportioning design method based on vibration test method

A technology of cement-stabilized crushed stone and mix ratio design, which is applied to chemical instruments and methods, preparation of test samples, specific gravity measurement, etc., can solve problems such as complicated operation, reduction of actual dosage of inorganic binder, loss of water content, etc. It achieves the effects of good crack resistance and erosion resistance, saving cement consumption and high dry density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention or invention are described in further detail below in conjunction with accompanying drawing:

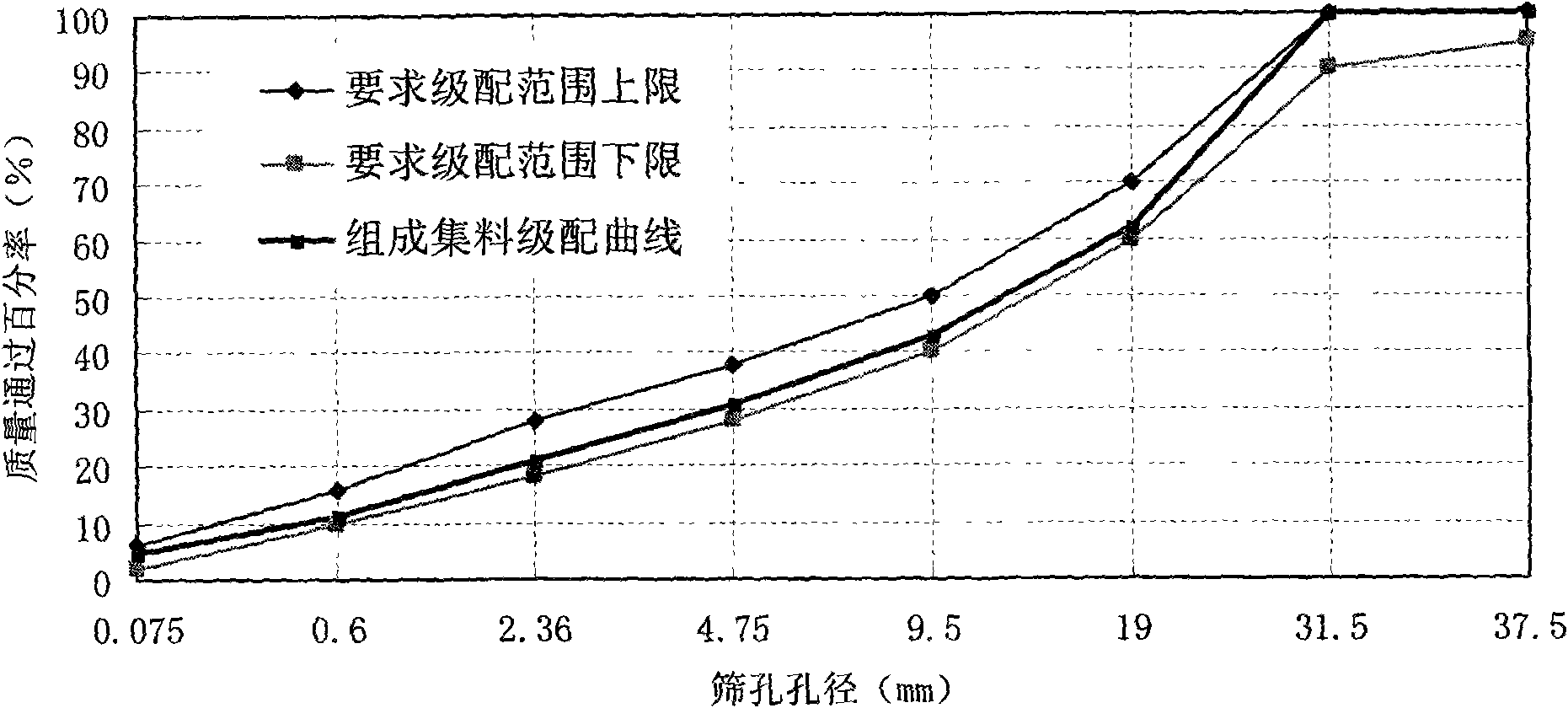

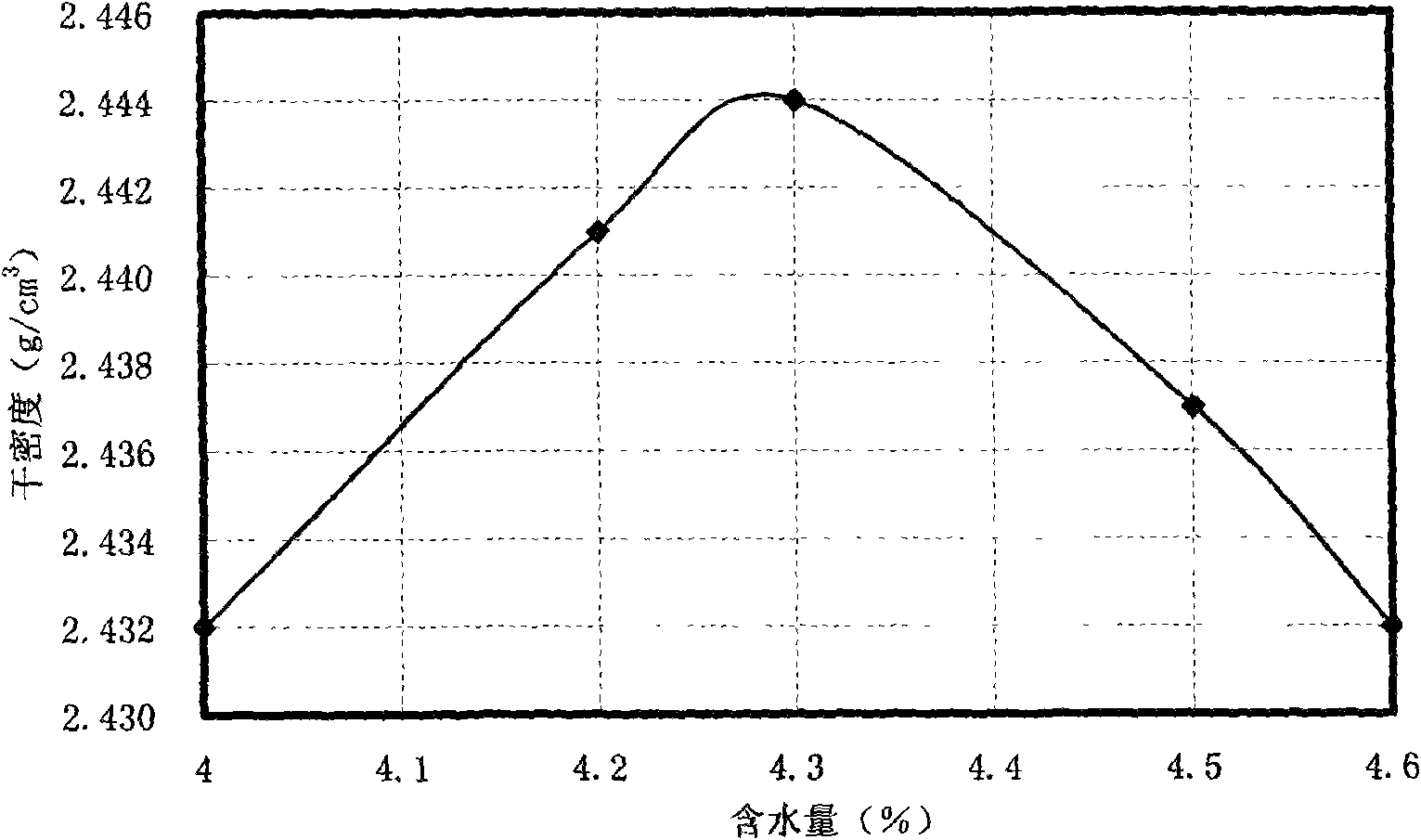

[0041] see figure 1 , 2 , the design method of anti-cracking cement stabilized macadam mixture ratio based on the vibration test method, the method follows the following steps:

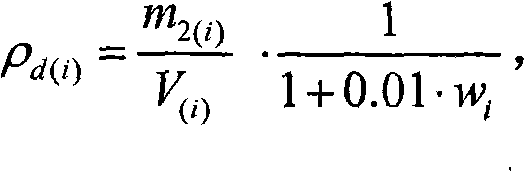

[0042] (1) Prepare skeleton-dense graded aggregates, the skeleton-dense graded aggregates are mineral mixtures composed of aggregates with different particle size specifications; the skeleton-dense graded aggregates have a particle size less than 37.5 mm aggregates account for 95-100% of the mass percentage of the graded aggregates; the aggregates with a particle size of less than 31.5 mm in the skeleton-dense graded aggregates account for 95-100% of the mass percentage of the graded aggregates; The mass percentage of aggregates with particle diameters less than 19mm in the skeleton-dense graded aggregates is 60-70%; the aggregates with particle diameters less than 9.5mm in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com