Testing device for quickly detecting flow property parameters of air passage of internal combustion engine

A flow performance and test device technology, applied in the direction of internal combustion engine testing, etc., can solve the problems of reducing the test accuracy of the airway steady flow test bench, increasing the cost, noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

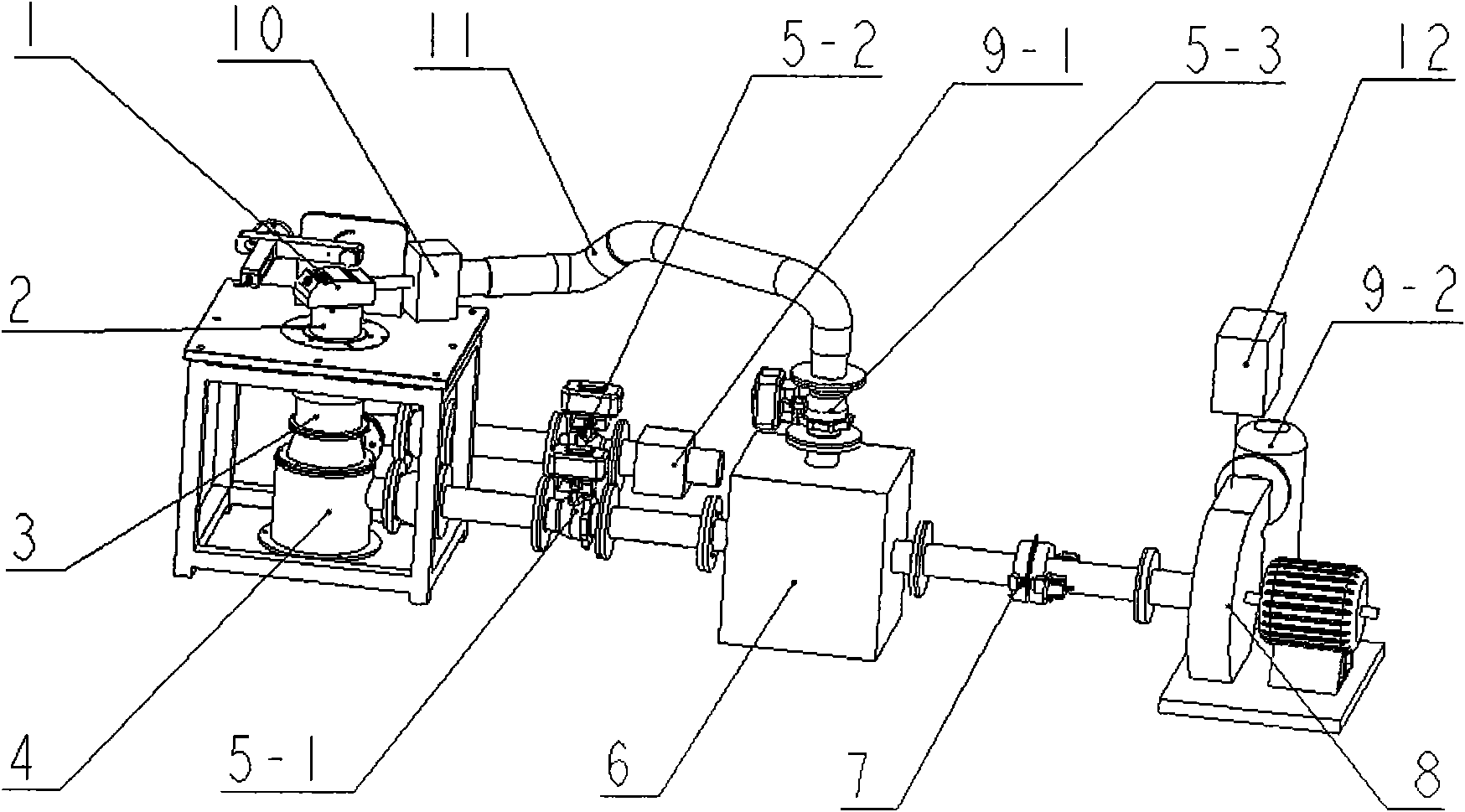

Method used

Image

Examples

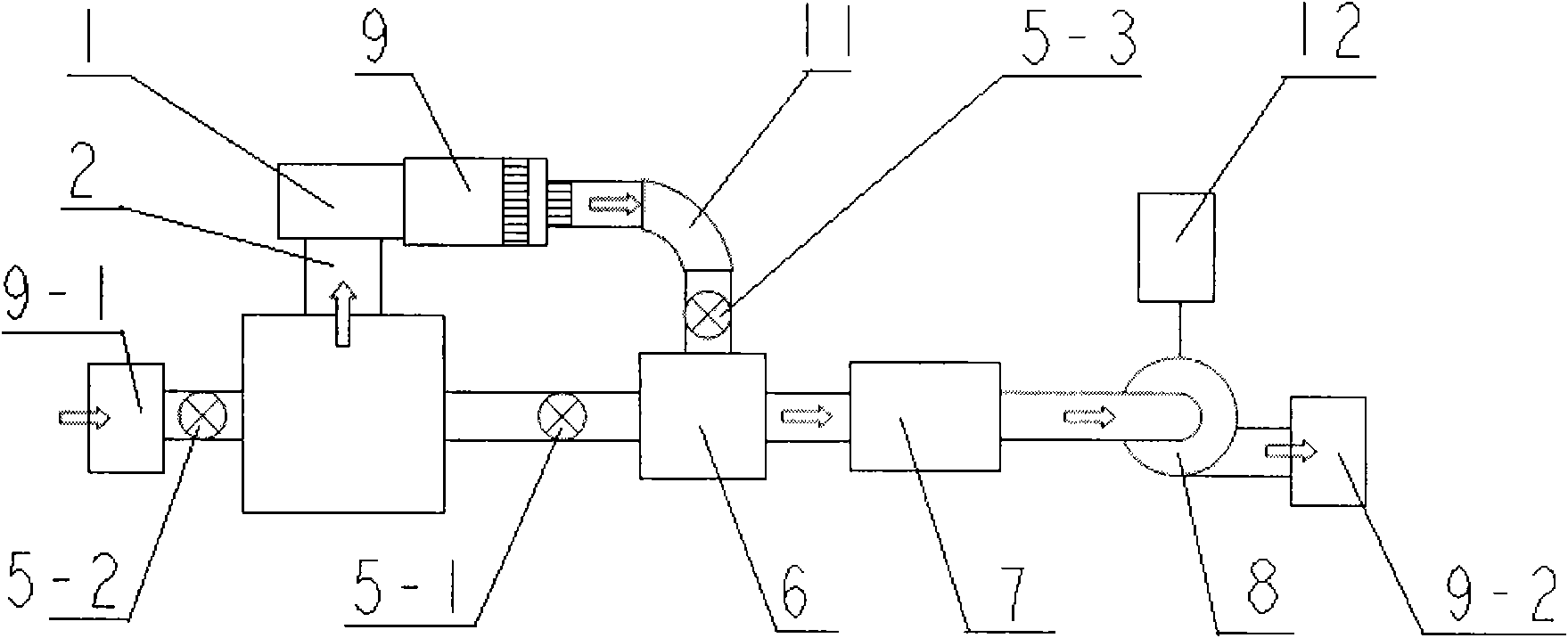

Embodiment 1

[0012] Exhaust duct steady flow test. The maximum valve lift is 10mm, and the bore is 100mm. Place the cylinder head under test on the cylinder liner. The first electric ball valve is closed, the second and third electric ball valves are opened, the valve lift is adjusted to 1mm, the intake valve lift is always 0mm, and the airway pressure difference is set to 5Kpa. Start the fan, the air flow direction is as follows figure 2 As shown by the arrow, through the first air filter→pressure regulator barrel→momentum meter→cylinder liner→air passage (exhaust passage)→airflow comber→hose→pressure regulator box→flow meter→induced fan→second air filter. There is a pressure tap at the place where the top surface of the cylinder liner is 1.75 times lower than the bore (175mm downward from the top surface). The difference between the atmospheric pressure and the pressure here is the airway pressure difference. The frequency adjusts the speed of the induced draft fan to maintain the a...

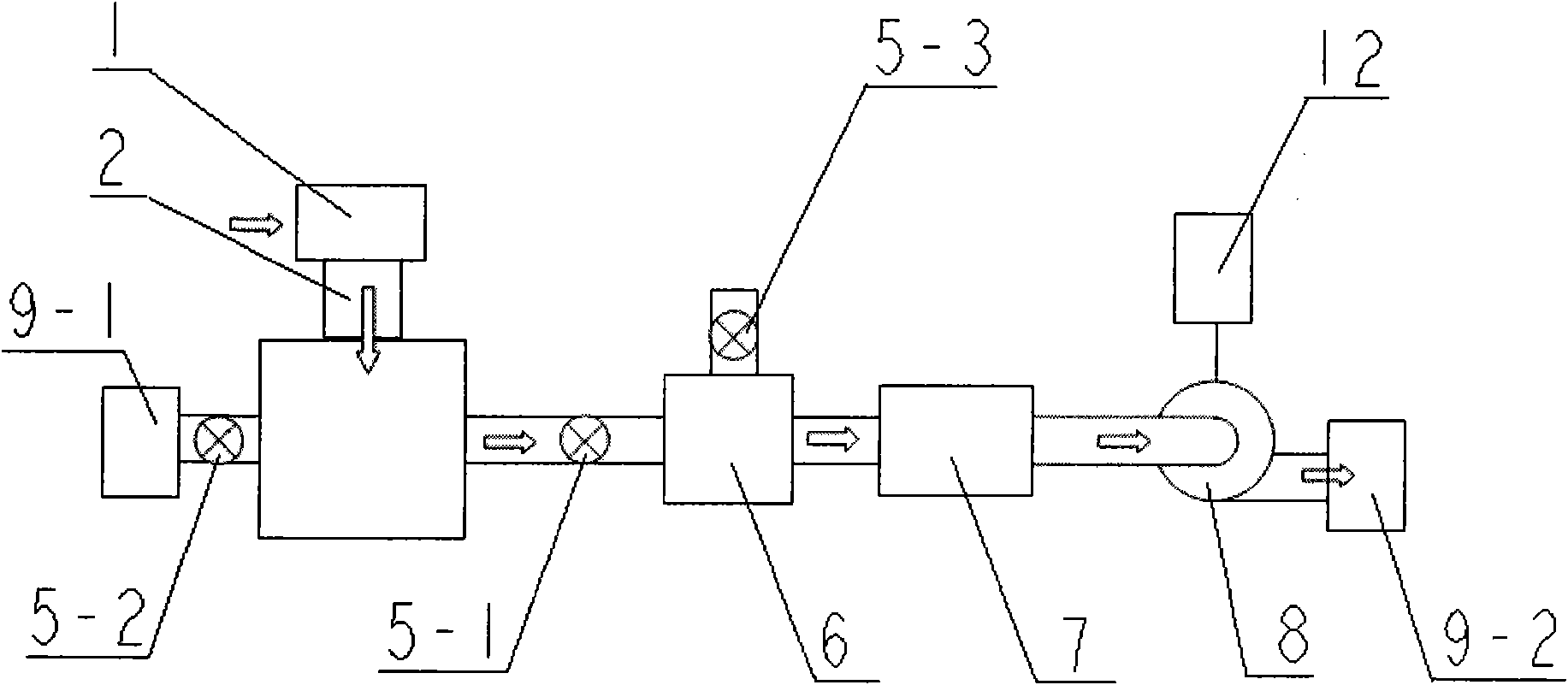

Embodiment 2

[0014] Inlet steady flow test. On the basis of Example 1, the test speed is further improved. The foregoing conditions are the same as in Embodiment 1, the intake valve lift is adjusted to 10 mm, and the exhaust valve lift is always 0 mm. Start the induced draft fan, the air flow direction is as follows image 3 As shown by the arrow, through the air duct (intake duct)→cylinder liner→momentum meter→pressure regulator tank→pressure regulator box→flow meter→induced fan→the second air filter. The airway pressure difference is set to 5Kpa under the valve lift of 10mm, and the air flow in the cylinder liner is always in a fully developed turbulent state. Then, the computer controls the frequency converter to adjust the speed of the induced draft fan so that the airway pressure difference is 5Kpa. When the pressure is stable Then measure the flow coefficient and eddy current intensity, then change the valve lift to 9mm, keep the frequency converter unchanged, the flow section of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com