IGBT heat dissipation device of frequency-variable controller and method thereof

A frequency conversion controller and heat dissipation device technology, applied in the field of frequency conversion home appliances, can solve the problems of reducing and optimizing PCB board structure design, disadvantages, etc., to improve circuit reduction and optimization design, reduce overall design and use cost, reduce The effect of installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

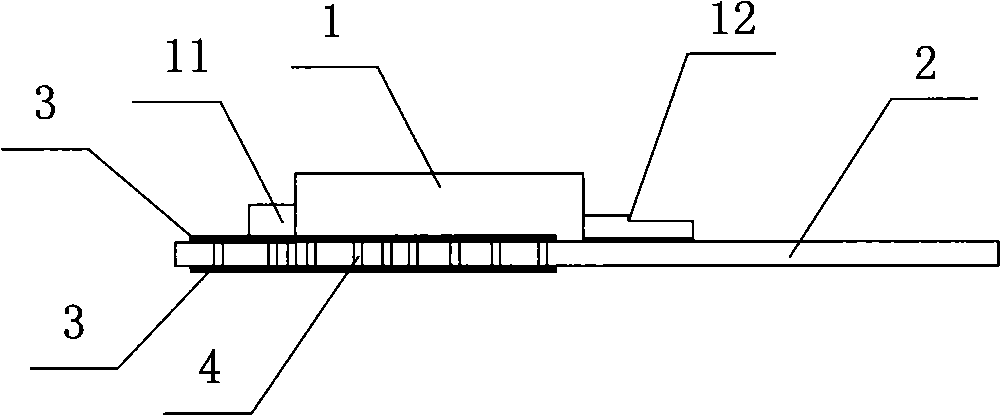

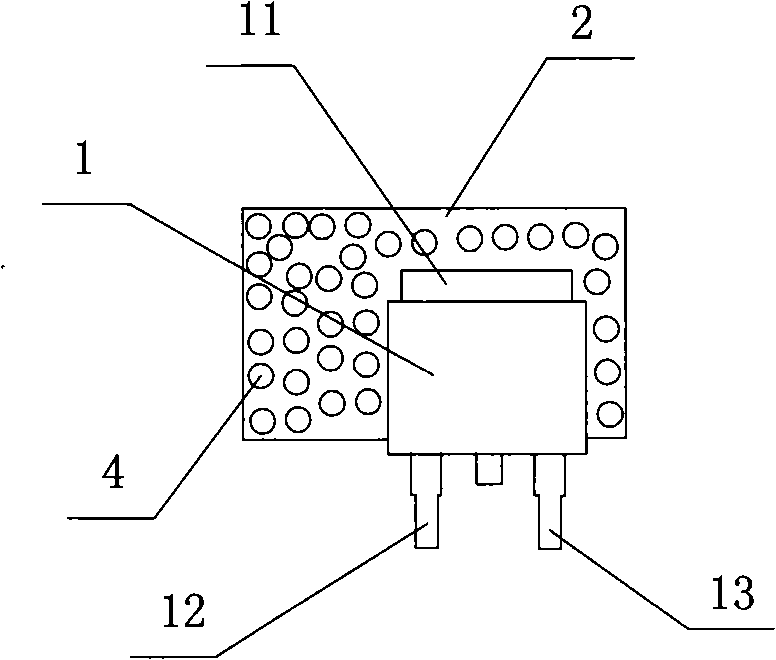

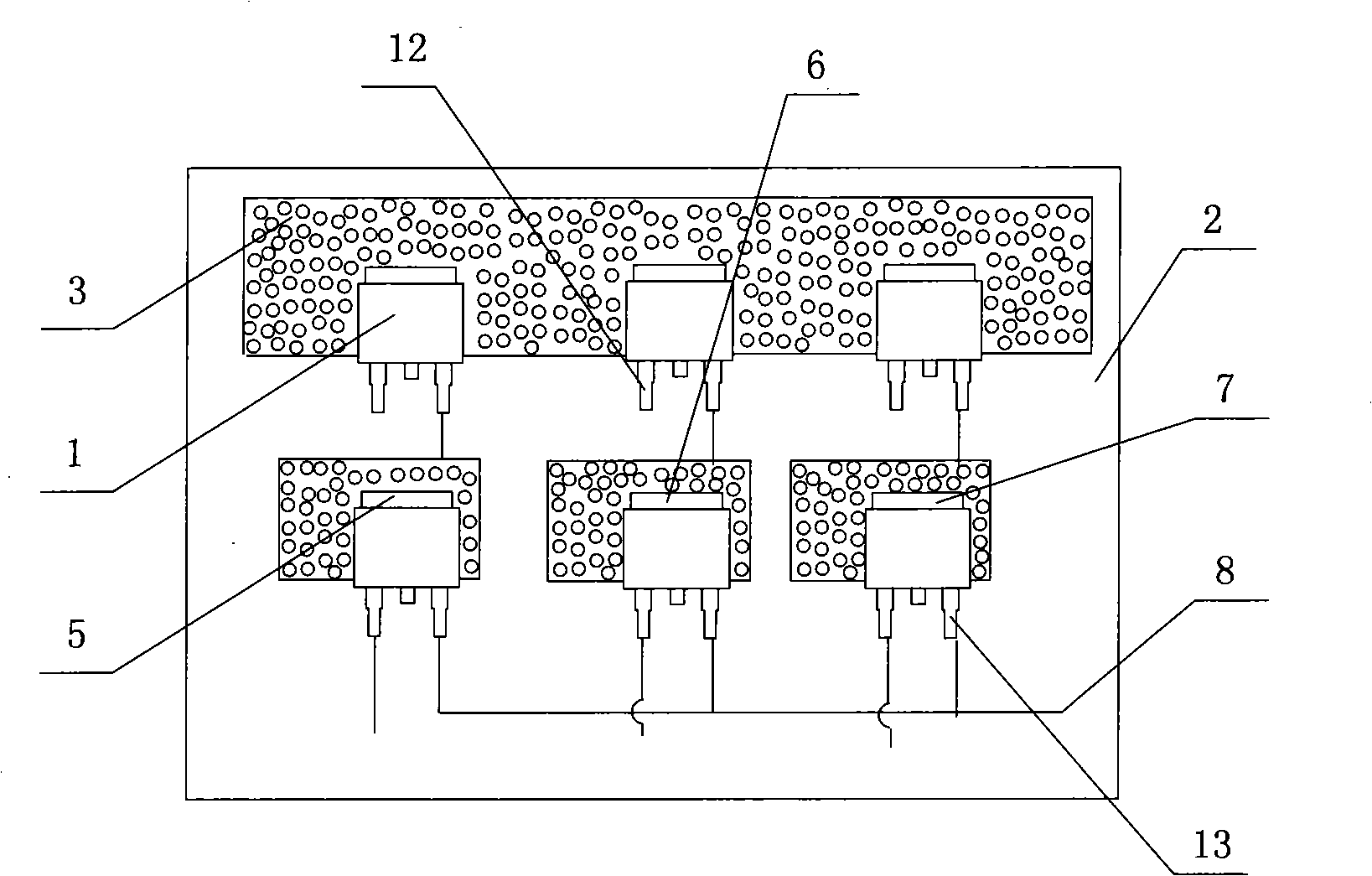

[0028] Example 1, such as Figure 1 to Figure 3 As shown, the IGBT cooling device of the variable frequency controller includes a PCB board 2 on which six IGBT1 are installed. in,

[0029] The six IGBT1s are bridge-connected and directly soldered on the PCB 2, a layer of tin layer 3 is coated on both sides of the PCB 2, and several transparent holes penetrating through the PCB 2 are arranged on the PCB 2. Tin via 4.

[0030] The through-tin through hole 4 can play the role of circuit connection and heat conduction.

[0031] The source electrodes 11 of the six IGBTs 1 are all soldered to the tin layer on one side surface of the PCB 2 .

[0032] The source level 11 is directly welded to the PCB board 2 , which can play the role of fixing the IGBT, and at the same time, the larger contact area of the source level 11 is used to improve heat dissipation efficiency.

[0033] Such as image 3 As shown, the solder layer of IGBT1 is the 310V voltage input end of the power circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com