Hickory nut slicing machine

A pecan and slicing machine technology, applied in sawing equipment, wood processing appliances, circular saws, etc., can solve the problems of uneven thickness, low work efficiency, high labor intensity, etc., and achieve simple and convenient operation, uniform thickness and labor. low intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

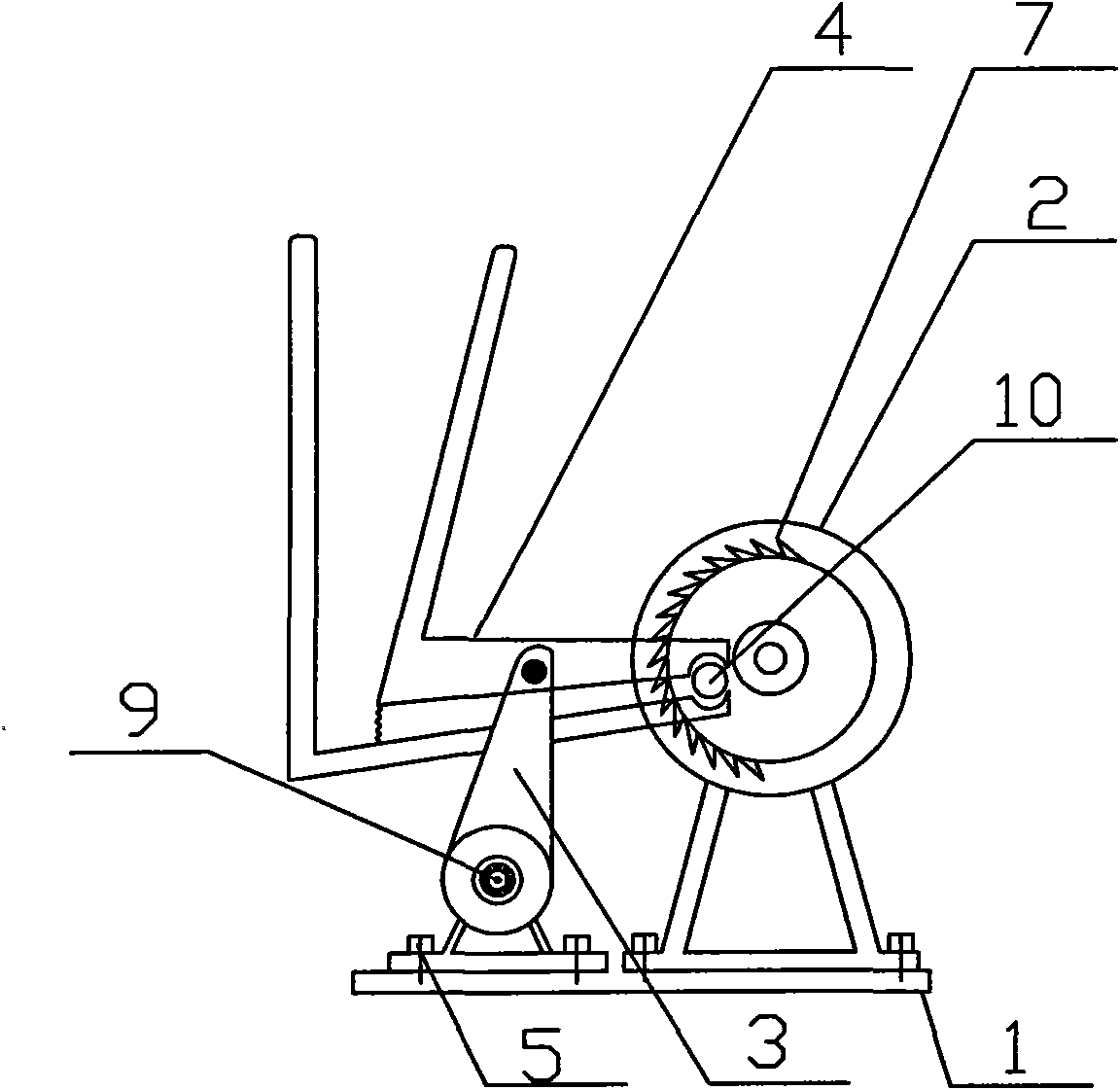

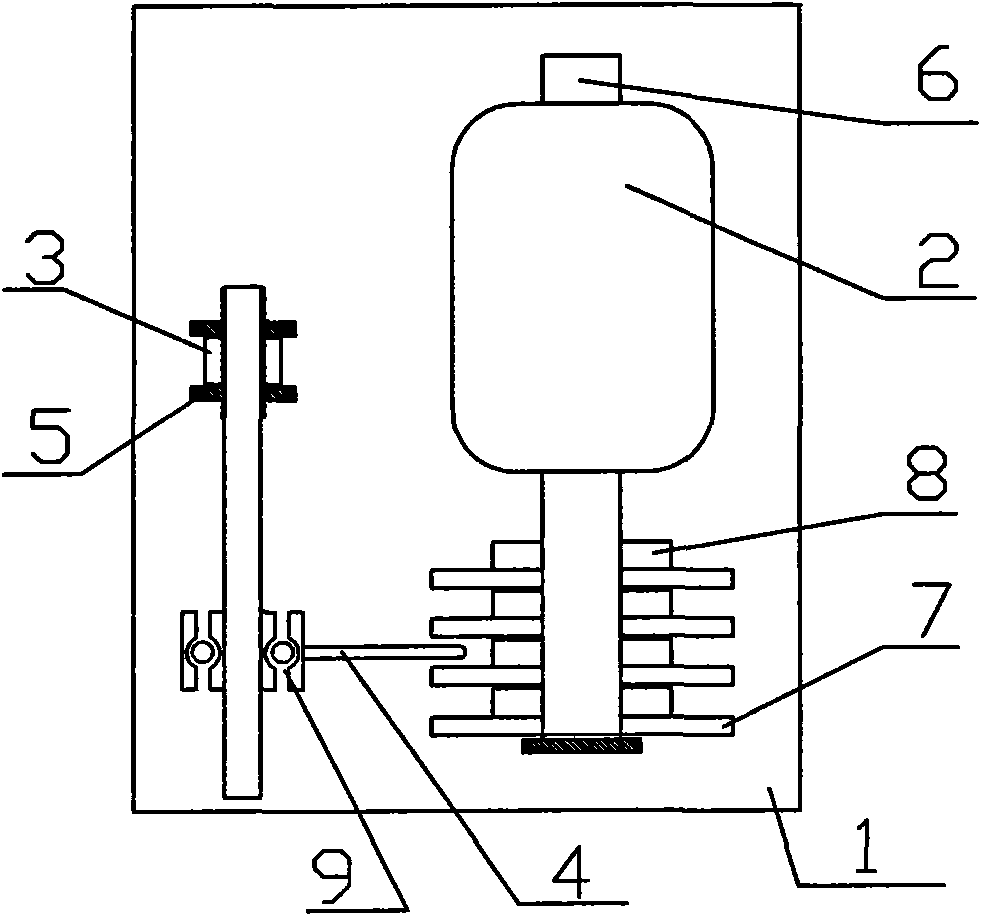

[0012] Such as figure 1 , figure 2 As shown, a hickory slicer includes a base 1, a motor 2, a clamp bracket 3, and a clamp 4 for clamping hickory 10; one side of the base is equipped with a motor, and the other side of the base is equipped with an adjusting nut 5 is fixedly connected with the clamp bracket, the upper part of the clamp bracket is fixedly connected with the lower clamping rod of the clamp, and is hinged with the upper clamping rod of the clamp. It is characterized in that the motor shaft 6 is also equipped with a saw blade 7 With the spacer 8, the spacer is located between adjacent saw blades; the clamp bracket is also equipped with a bearing 9 that makes the clamp bracket move back and forth, and is used for adjusting the nut through the bearing when adjusting the lower position of the clamp bracket. The rotation of the blade moves the clamp attached to the upper part of the clamp bracket down between adjacent saw blades.

[0013] The handle of the clamp is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap