Air-storage engine, pressurizing system and method thereof, and emission reducing system and method thereof

An engine and gas storage technology, applied in engine components, engine control, combustion engines, etc., can solve problems such as increased discharge pressure, increased cost, and prolonged catalyst light-off time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

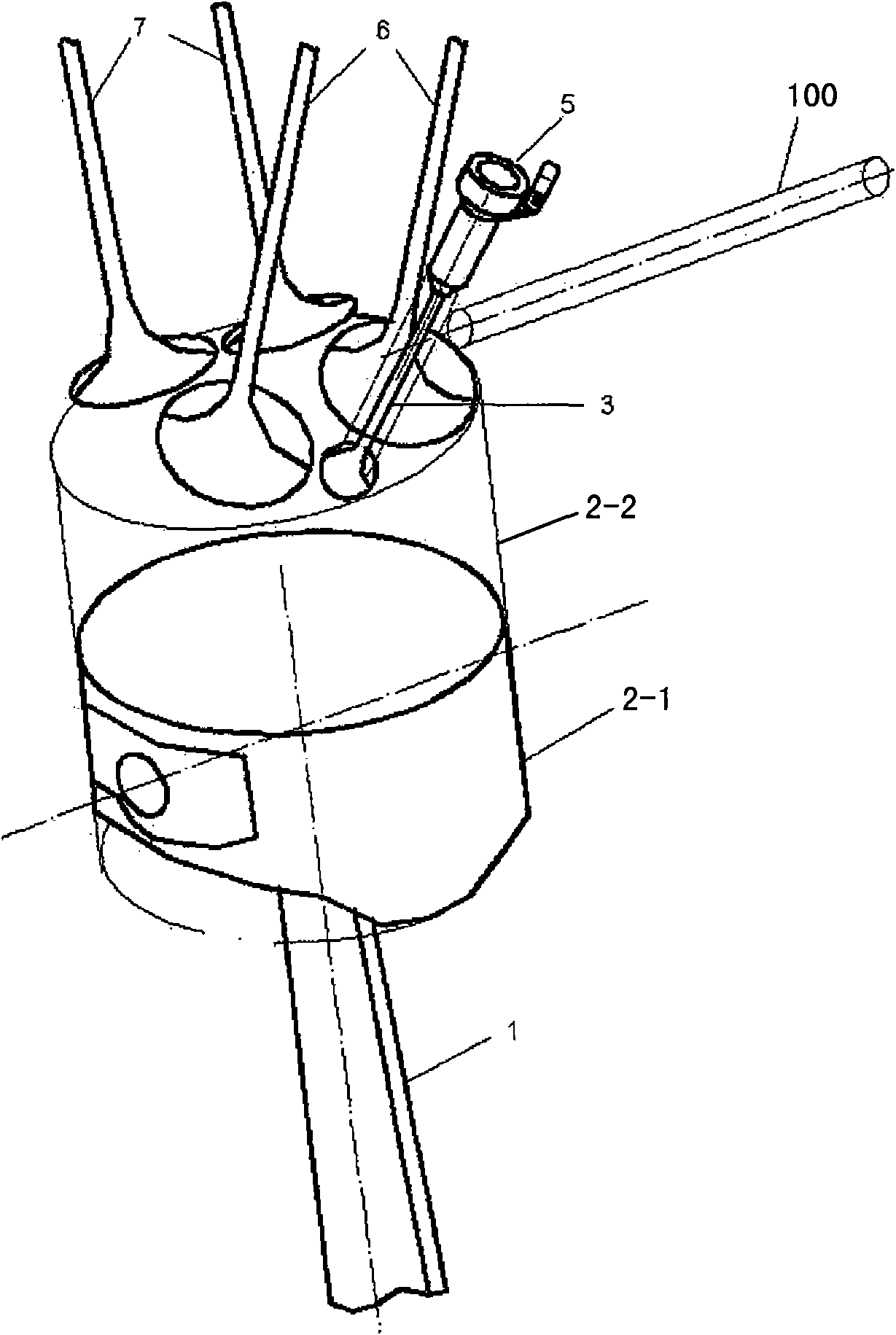

[0026] Such as figure 1 As shown, the air storage engine of the present invention has a reciprocating engine body composed of a connecting rod 1, a piston 2-1, and a cylinder 2-2, and also has an exhaust valve 7, an intake valve 6, and a pump valve 3. figure 1 Only a single-cylinder structure is shown in , but the structure of multiple cylinders can be understood from this, that is, if the reciprocating engine body has multiple cylinders, their pump valves 3 share the first pipeline 100 . The pump valve 3 is equipped with a solenoid valve 5, and the solenoid valve 5 is electrically connected with the engine management system.

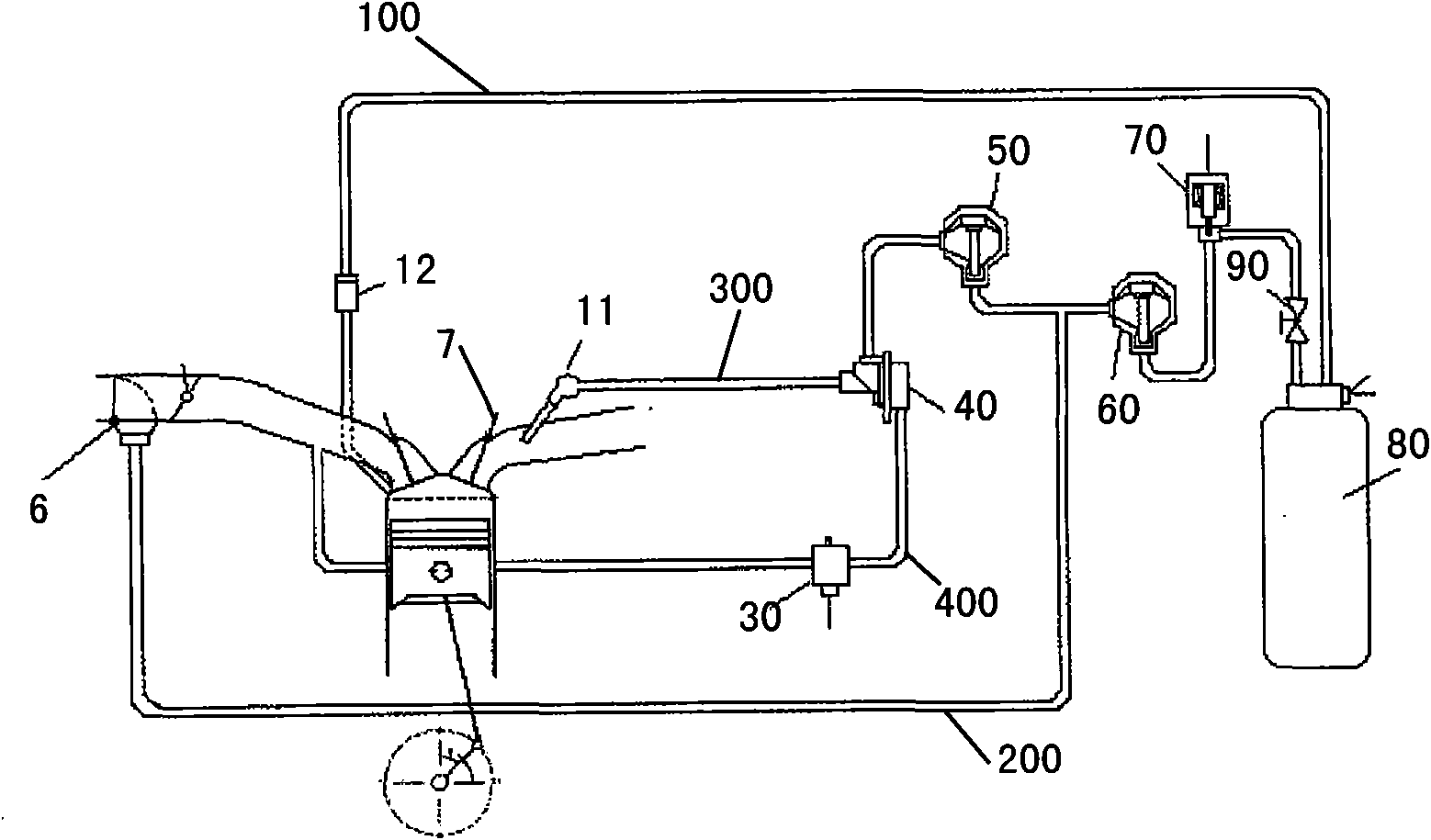

[0027] Such as figure 2 As shown, the first pipeline 100 connects the pump valve 3 and the gas storage device 80 together. The second pipeline 200 connects the intake valve 6 and the gas storage device 80 together. The third pipeline 300 connects the exhaust valve 7 and the gas storage device 80 together.

[0028] A one-way valve 12 is provided in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com