Pressurized multi-stage absorption, condensation and adsorption module combined organic waste gas recovery method

A technology of organic waste gas and recovery method, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of low condensation temperature, high energy consumption, poor absorption effect at atmospheric pressure, etc., and achieve the effect of high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

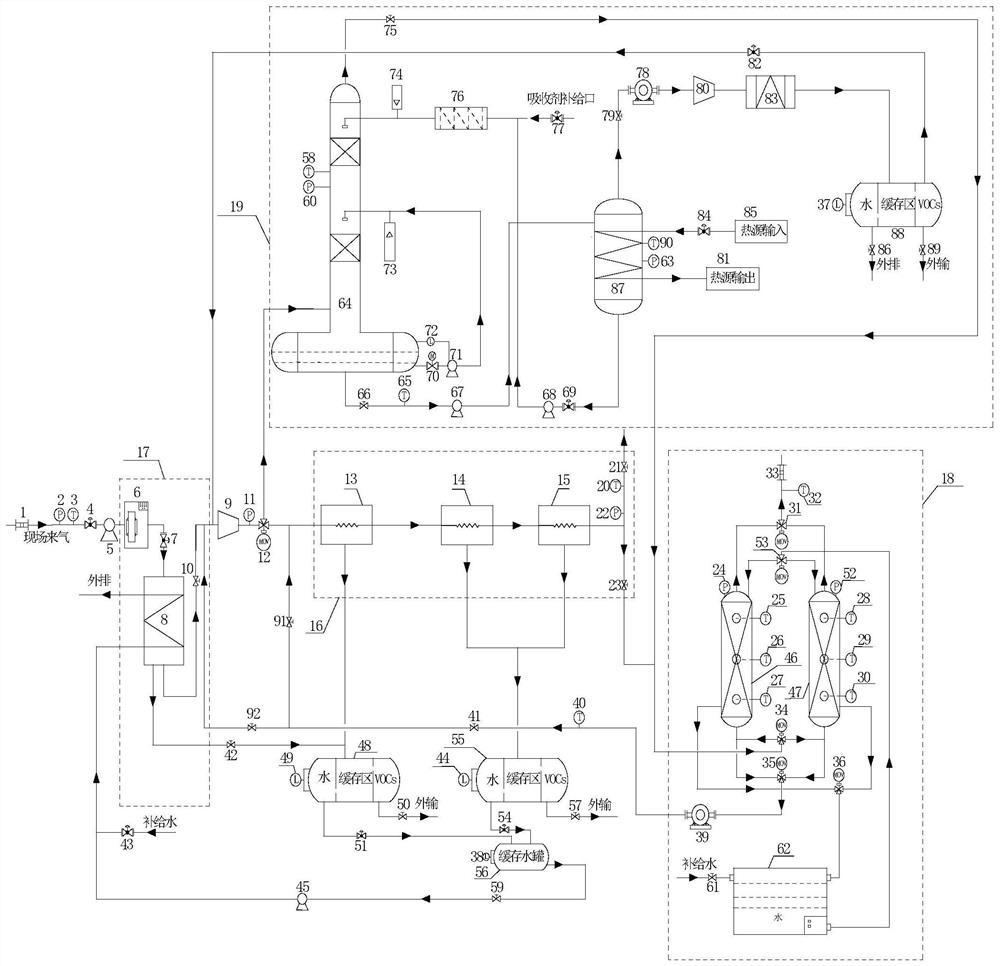

[0028] A large amount of crude oil gas is produced during the loading and unloading of crude oil by a railway tank car, which is easily soluble in diesel oil, and the emission is 1000 m 3 / h, the concentration is 502.62 g / m 3 , the oil and gas emission concentration after treatment is required to be less than 80 mg / m 3 . Aiming at the requirements of low discharge of VOCs with large flow rate and high concentration, which are easily soluble in absorbent, the pressurized multi-stage "absorption + adsorption" recovery method of the present invention is used to efficiently recover them. figure 1 Be explained.

[0029] (1) The technical scheme of the present invention is as follows:

[0030] Pressurized multi-stage "absorption + adsorption" recovery method: the main equipment required by this method includes flame arrester 1, pressure sensor 2, 11, temperature sensor 3, 40, ball valve 4, 43, 51, 54, air pump 5, three Through valve 12, compressor 9, gate valve 41, 42, 50, 57, 5...

Embodiment example 2

[0051] A large amount of organic waste gas was emitted during the production process of a chemical plant, mainly C 3 and above heavy components, the content of light hydrocarbons is less, and the discharge volume is 500 m3 / h, the concentration is 363.25 g / m 3 , the oil and gas emission concentration after treatment is required to be lower than 60 mg / m 3 , Aiming at the low emission requirements of VOCs with medium flow rate, high concentration and low light hydrocarbon content, the recovery method of pressurized multi-stage "condensation + adsorption" in the present invention is used to recover them efficiently. figure 1 Be explained.

[0052] (1) The technical scheme of the present invention is as follows:

[0053] Pressurized multi-stage "condensation + adsorption" recovery method: the main equipment required by this method includes flame arrester 1, pressure sensor 2, 11, temperature sensor 3, 40, ball valve 4, 43, 51, 54, air pump 5, three Through valve 12, compressor ...

Embodiment example 3

[0074] During the process of loading and unloading oil in an oil depot, a large amount of oil and gas are produced, the oil and gas components are complex, and the discharge volume is 1000 m 3 / h, the concentration is 623.49 g / m 3 , the oil and gas emission concentration after treatment is required to be less than 20 mg / m 3 . In view of the ultra-low emission requirements of VOCs with large flow, high concentration and complex components, the recovery method of pressurized multi-stage "absorption + adsorption + condensation" in the present invention is used to efficiently recover them. figure 1 Be explained.

[0075] (1) The technical scheme of the present invention is as follows:

[0076] Pressurized multi-stage "absorption + adsorption + condensation" recovery method: the main equipment required for this method includes flame arrester 1, pressure sensors 2, 11, temperature sensors 3, 40, ball valves 4, 43, 51, 54, and air pump 5 , three-way valve 12, compressor 9, gate v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com