An anti-backfire fuel flash swirl integrated nozzle

A swirl nozzle and anti-backfire technology, which can be used in combustion chambers, combustion methods, combustion equipment, etc., can solve the problems of underutilization and increased pollutant emissions, reduce production, meet low emissions, and suppress backflow. effect of fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015]The present invention will be further described in further detail below with reference to the accompanying drawings.

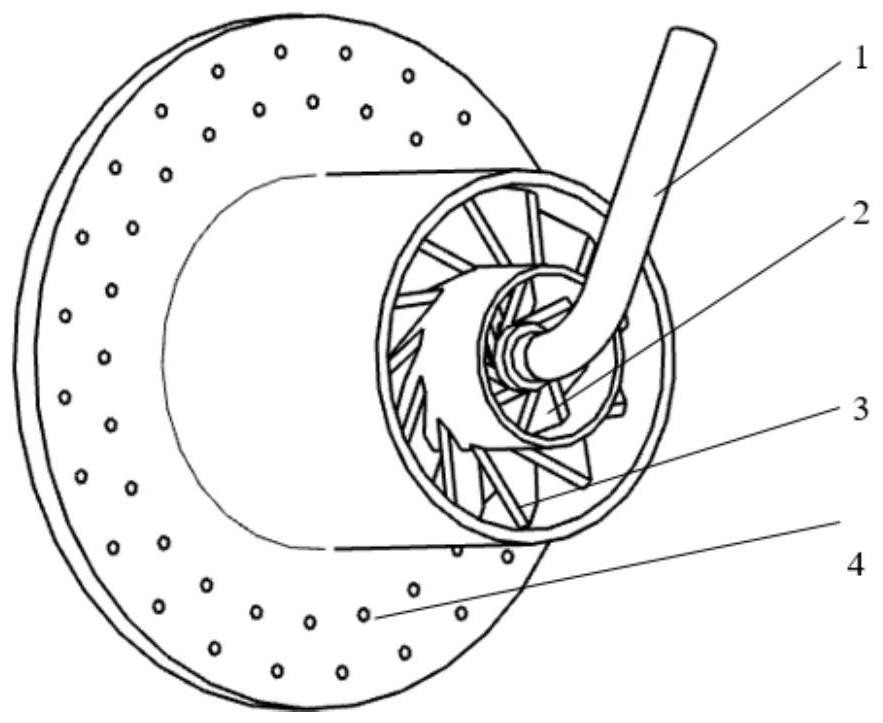

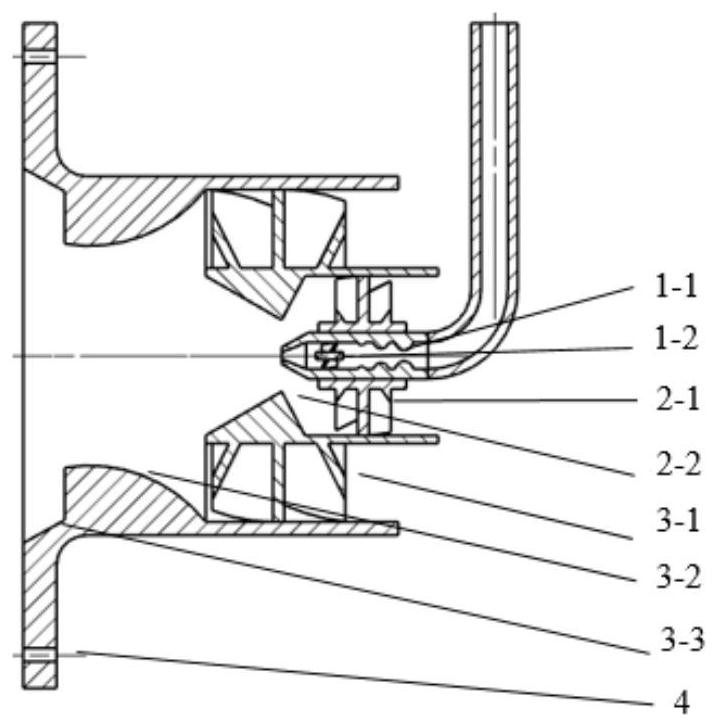

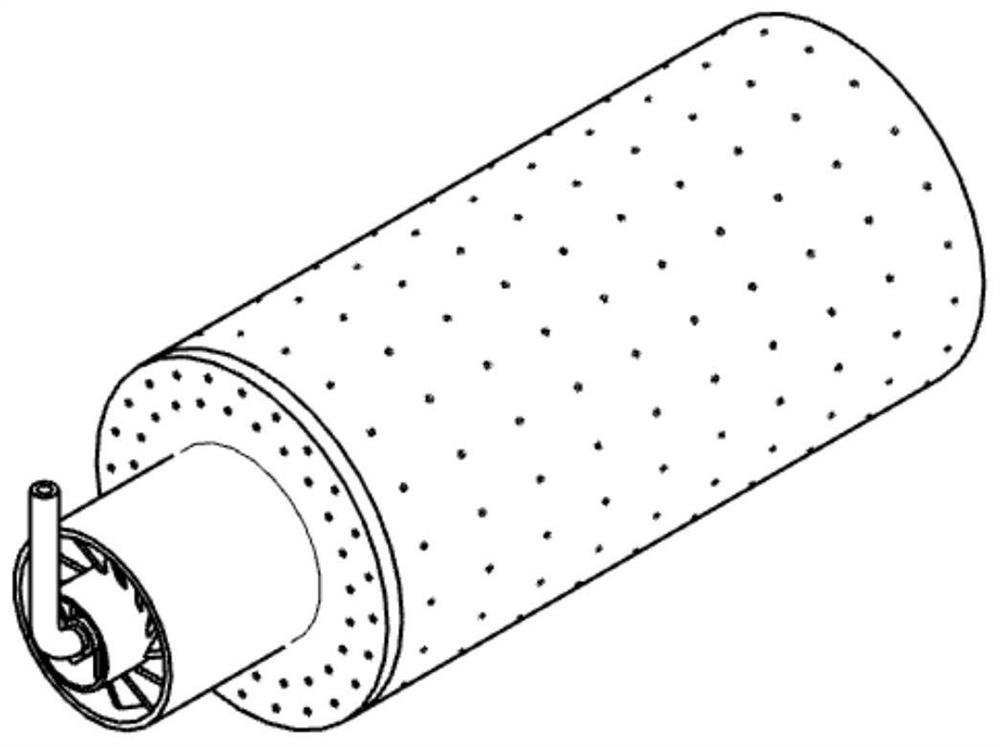

[0016]Such asFigure 1-2As shown, one anti-backflake vapor flow integrated nozzle, including: a pressure swirl nozzle 1 with a rough projection, a primary swirler 2 with contraction-expanded Wenta tube, a second stage of rear steps The swirl 3, the blow hole 4. The four components are arranged in a central annular, and the inner to the outside is sequentially azuriferous swirl nozzle 1 with a rough projection, a primary swirler 2 with contraction-expanded Withe, a secondary swirling of the rear stepped The machine 3, the blow hole 4, the center line of each component. The central fuel nozzle is a pressure swirling nozzle, a spray cone angle 90 °, a rough projection 1-1 and a swirl blades 1-2 in the fuel flow channel, and since the combustion chamber is much lower than the saturated steam corresponding to the fuel temperature. Pressure, overcritical fuel passes thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com