Self-vibration composite smoke tube with internally-inserted bent fins

A self-vibration, fin technology, applied in the directions of heat sinks, tubular elements, combustion methods, etc., can solve the problems of limited strengthening ability, damage to the laminar boundary layer of the inner wall, etc., to improve the finning ratio, comprehensive heat transfer performance, The effect of improving boiler efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

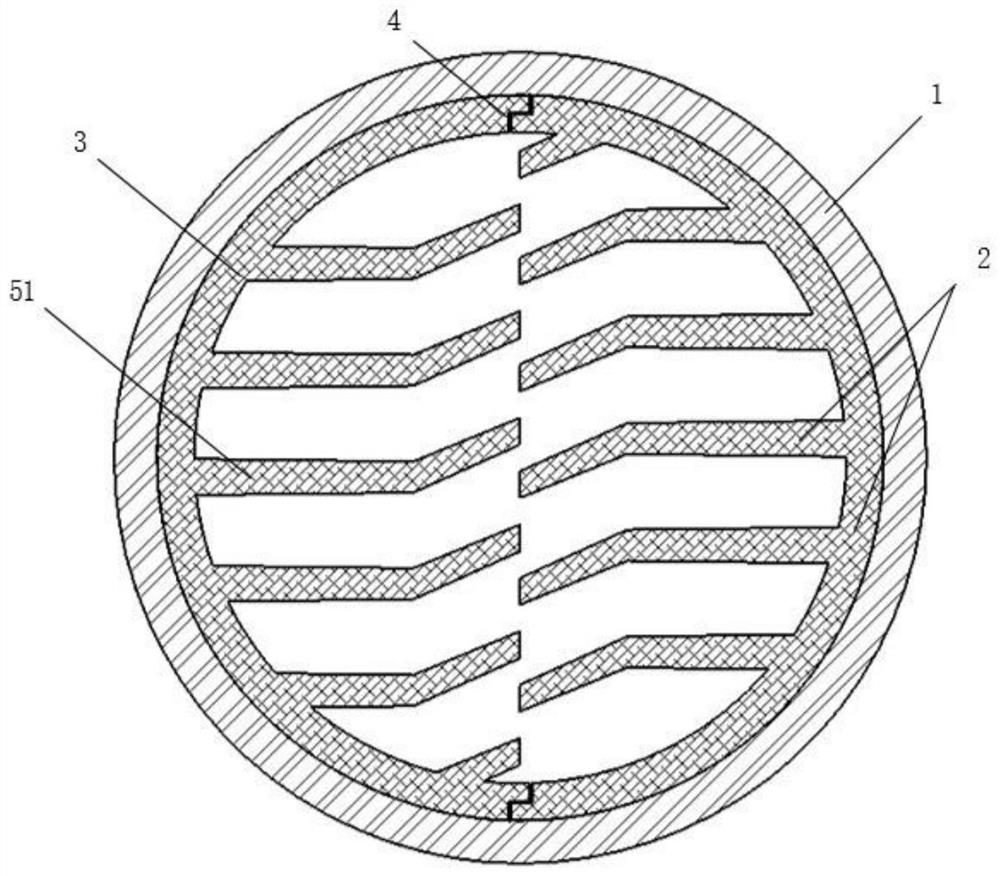

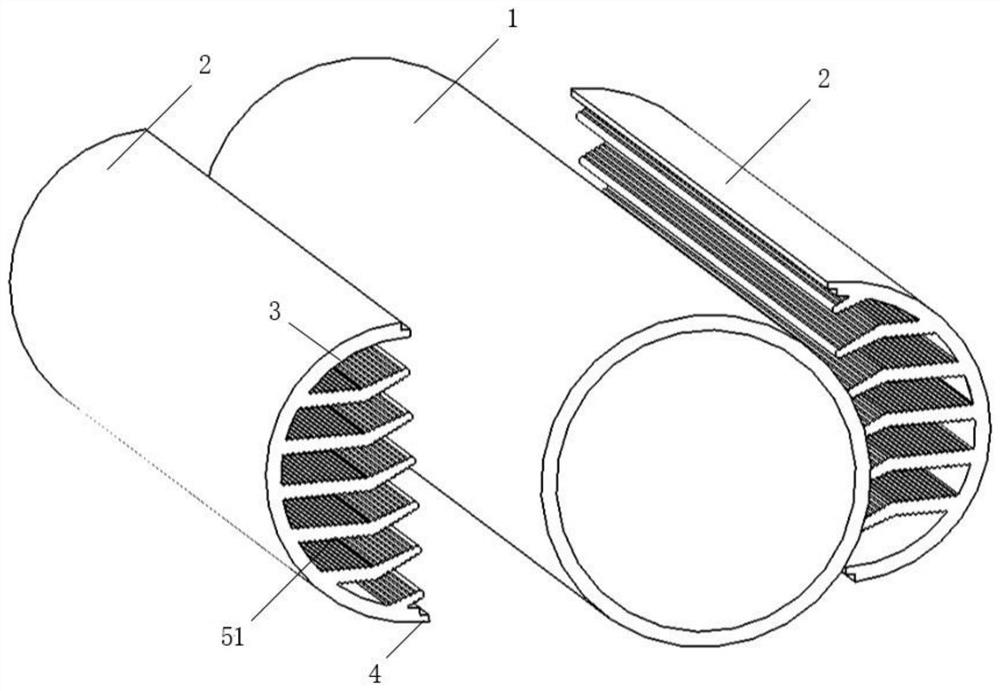

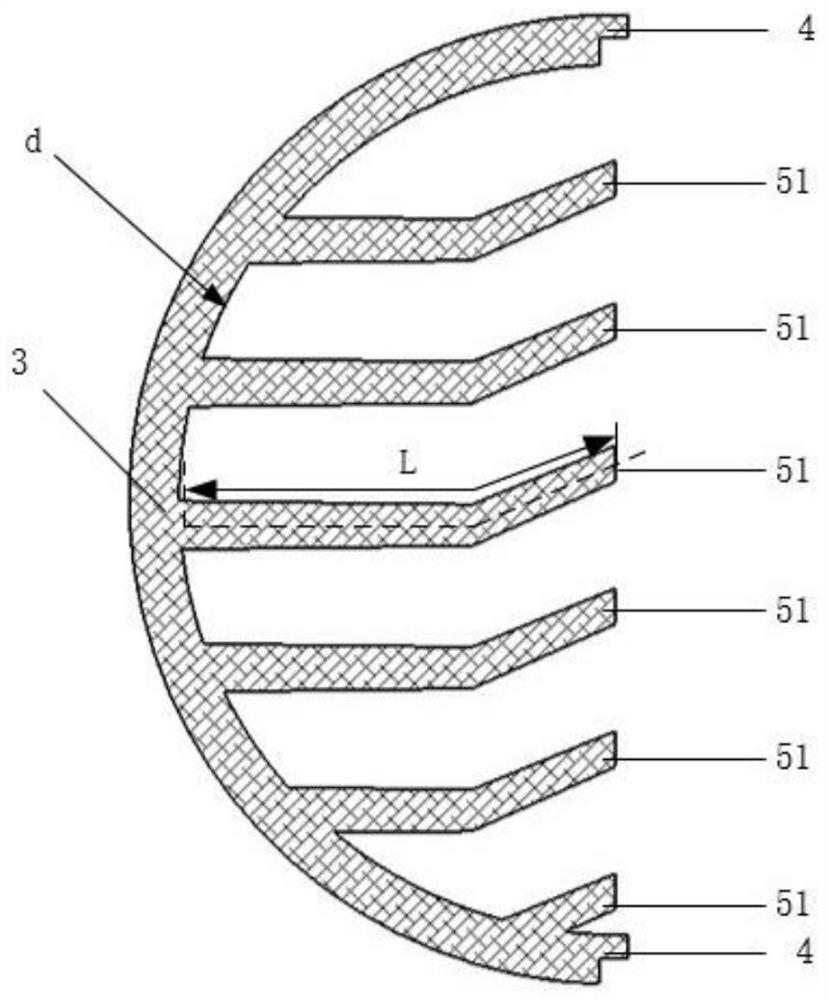

[0037] refer to Figure 1a , Figure 1b and Figure 1c , a self-vibrating interpolation bending fin composite smoke pipe, which consists of a light pipe 1 and a half-width fin 2; the symmetrical center of the cross-section of the two half-width fins 2 is the center of the light pipe 1, and a piece of half-width fin 2 is wound around After the center of the light pipe 1 is rotated by 180°, it can completely overlap with another half-width fin 2; the outer surface of the half-width fin 2 is closely attached to the inner surface of the light pipe 1; the half-width fin 2 includes a base pipe 3 and multiple A fin 5 is obtained by stretching a two-dimensional figure, and all sections perpendicular to the stretching direction are the same; the two ends of the base tube 3 are provided with a matching interface 4, and two half-width fins 2 form a full circle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com