Heat storage type combustor powered by liquid fuel

A liquid fuel and burner technology, applied in the directions of burners, combustion methods, combustion types, etc., can solve the problems of uneven distribution, reduced combustion efficiency, and high exhaust gas temperature, eliminate local high temperature areas, reduce heat loss, and improve The effect of combustion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

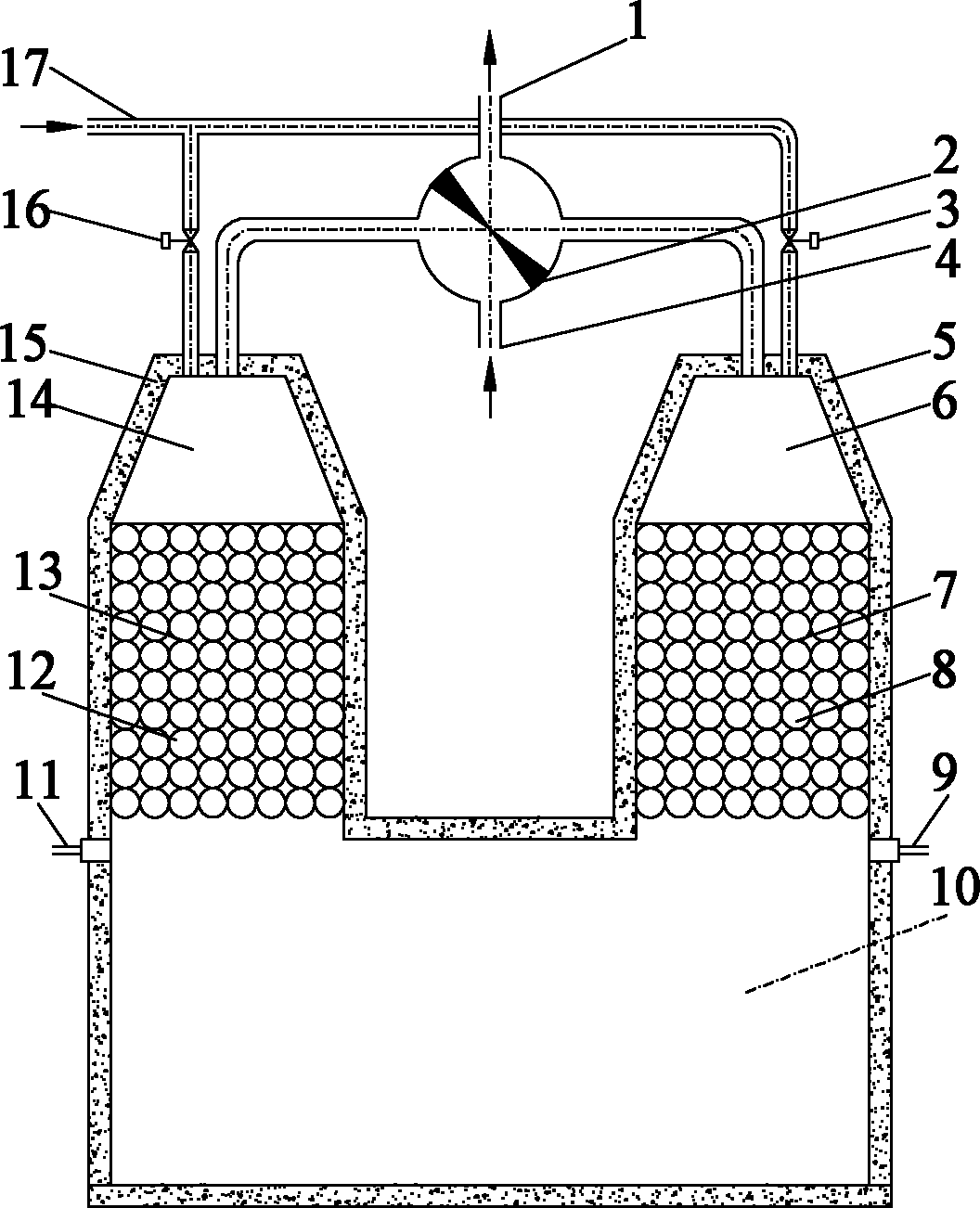

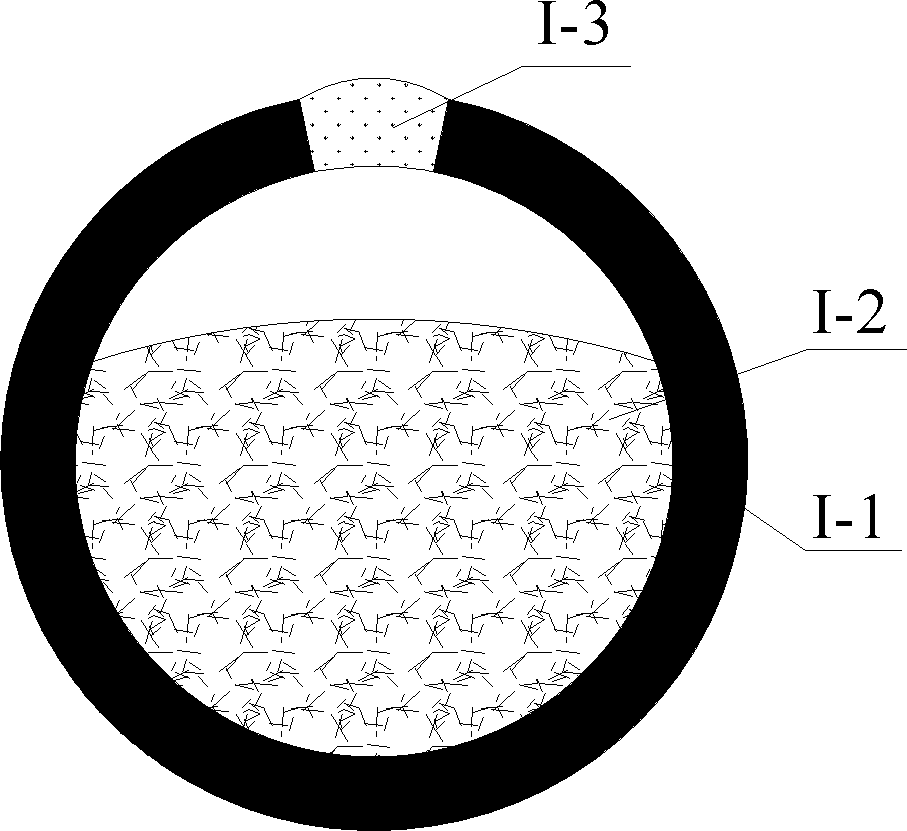

[0016] see figure 1 , the present invention includes two sets of regenerative combustors with the same structure, the regenerative combustors include top-down air-fuel premix chambers 6, 14 and pellet regenerators stacked with phase change regenerative pellets 8, 12 7, 13, the two regenerators are respectively connected with the combustion chamber 10 at the lower end, and the outer sides of the regenerator and the combustion chamber 10 are provided with insulation layers 5, 15, and are arranged in the combustion chamber 10 at the lower end of the two regenerators. There are igniters 9 and 11, and the upper ends of the two same regenerative combustion chambers are respectively connected with the liquid fuel supply pipe 17, the air-smoke two-position four-way valve 2 with the air inlet 4 and the smoke outlet, and the liquid fuel supply pipe 17 are provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com