Visible detection method of welding quality of circuit board based on support vector machine

A technology of support vector machine and welding quality, which is applied in the direction of optical testing flaws/defects, image data processing, instruments, etc., can solve the problems of high missed detection rate, low precision, slow speed, etc., and achieve high degree of automation and detection accuracy High, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

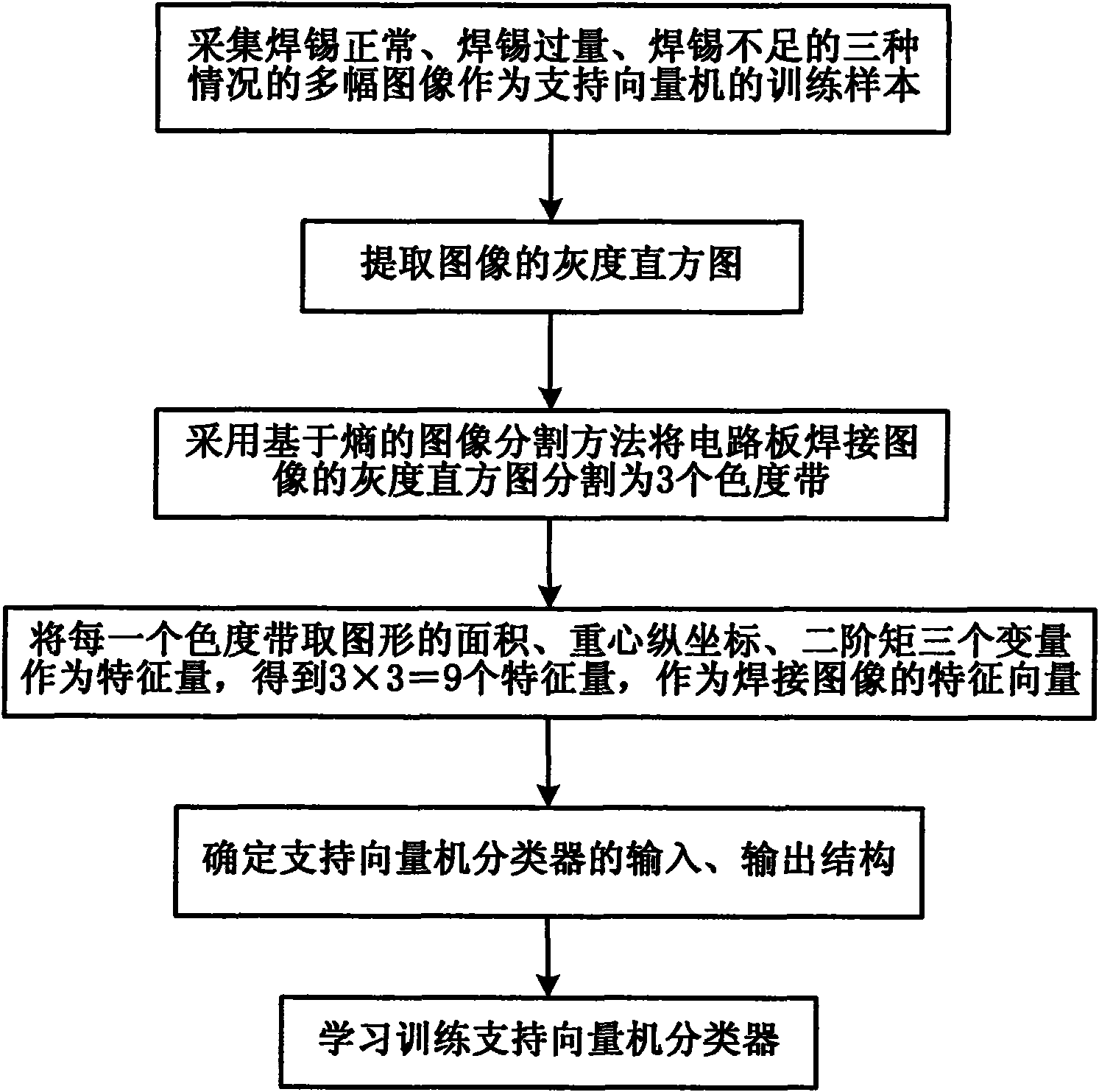

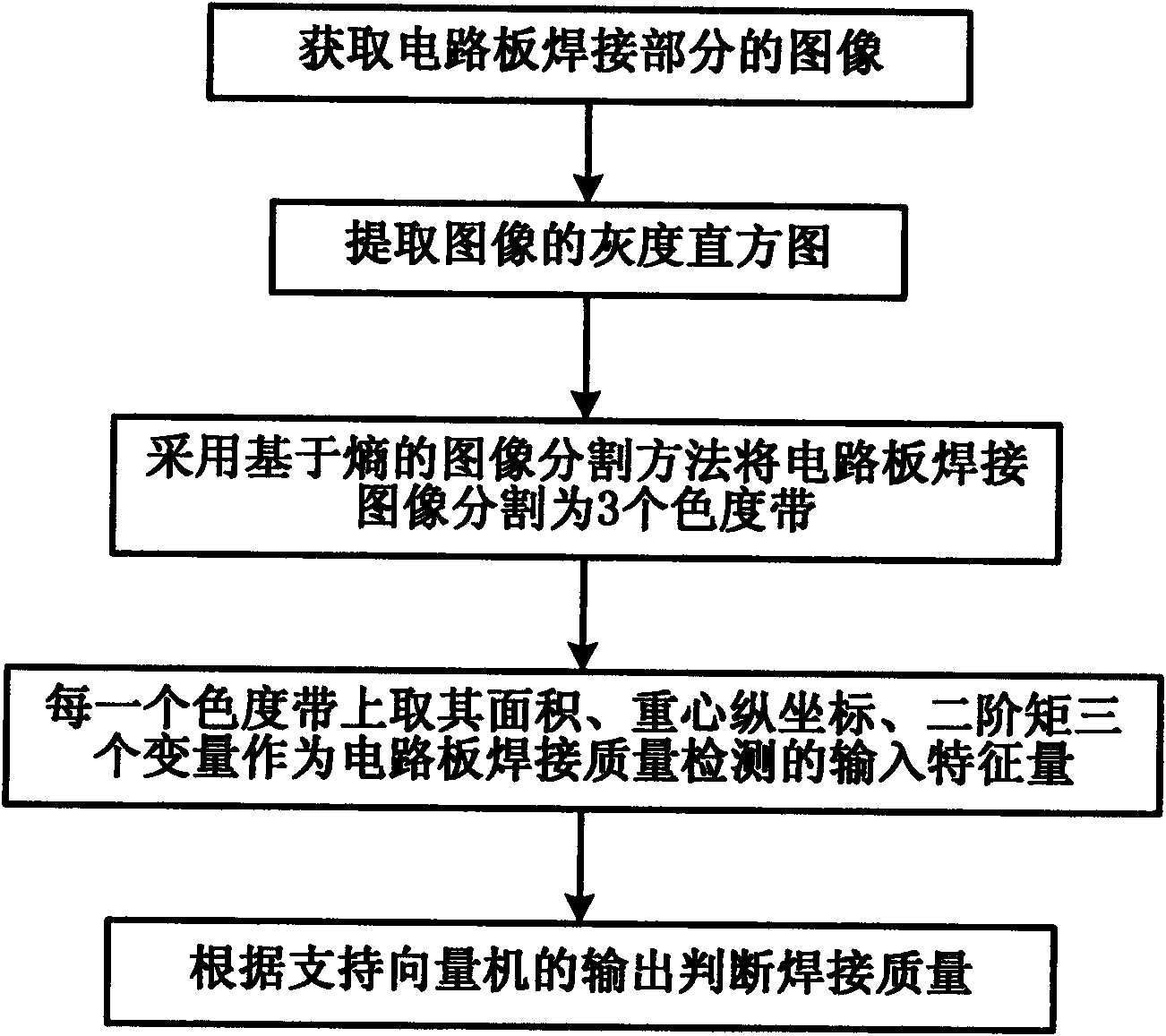

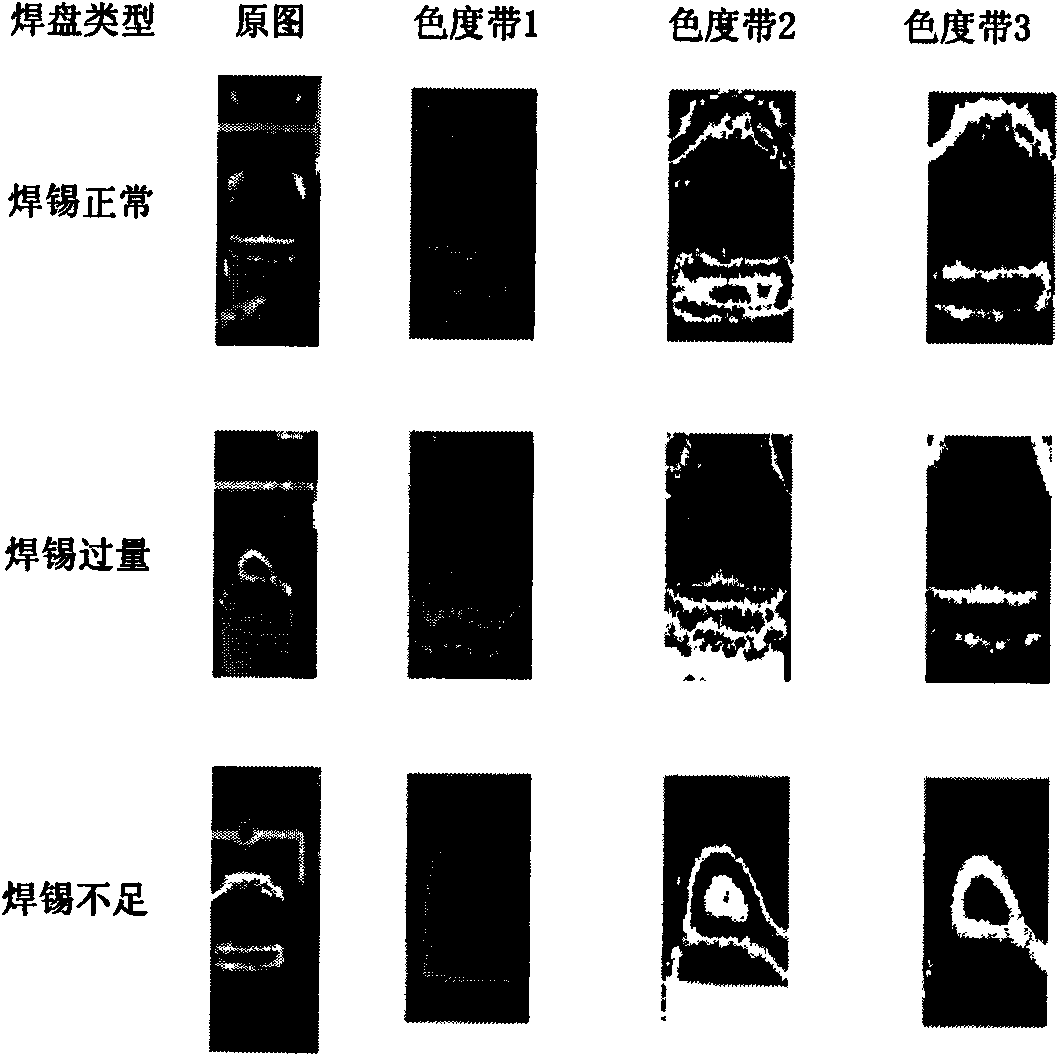

Method used

Image

Examples

Embodiment 1

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0042] 1. At first, the present invention adopts the digital camera to take the image of the soldering part of the circuit board, and extracts the grayscale histogram of the image.

[0043] The histogram of an image can be expressed as

[0044] p ( h ) = g ( h ) G - - - ( 1 )

[0045] In the formula, G represents the sum of image pixels, h represents the gray level, and g(h) represents the number of pixels whose gray level is h. The gray histogram is a function of the gray level, which indicates the number of pixels with each gray level in the image, and reflects th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com