Code type identification method and device used for numerical control machine

A code type and recognition method technology, applied in the field of code type recognition methods and devices of CNC machine tools, can solve problems such as low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

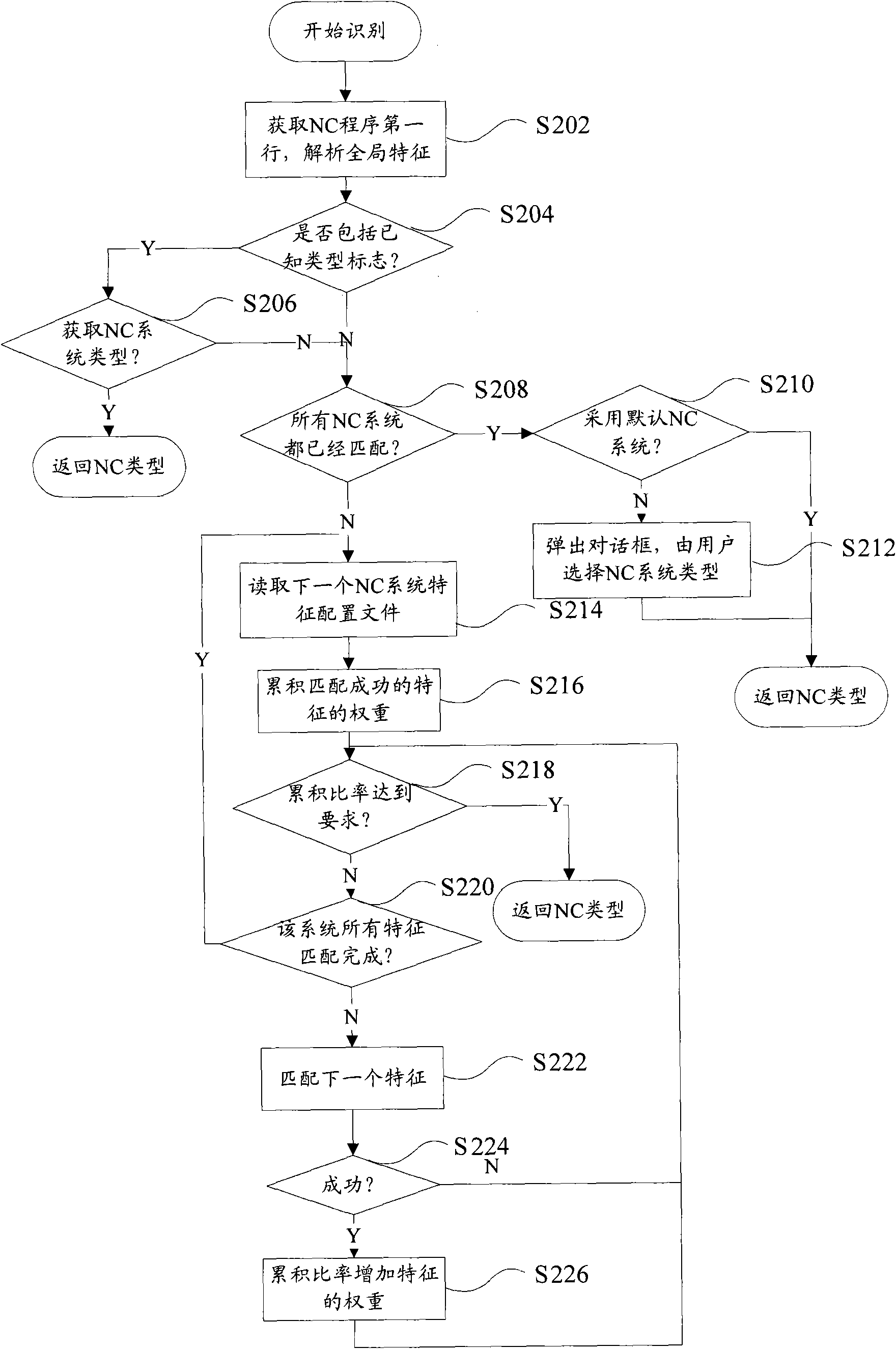

[0024] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings and the embodiments.

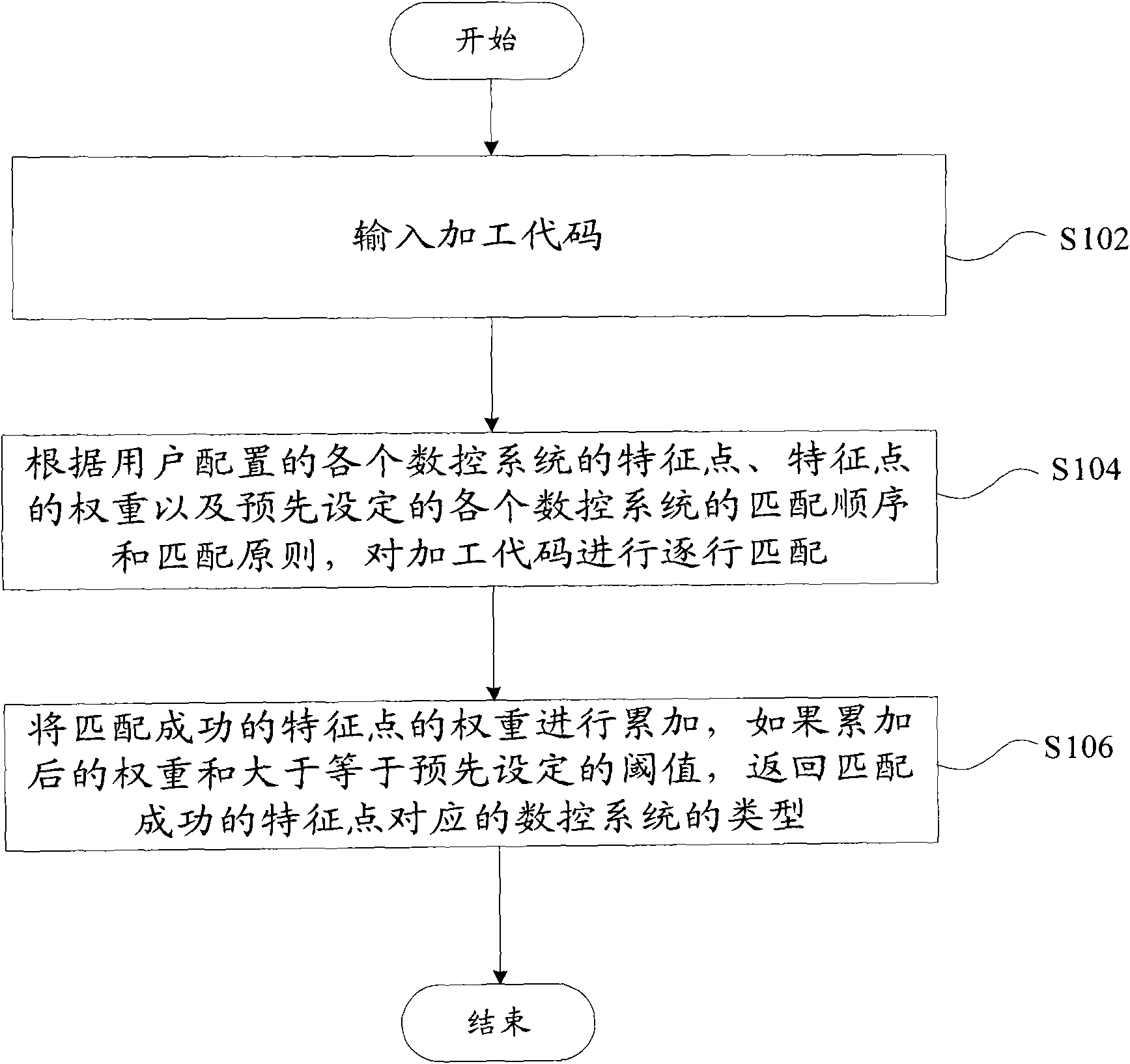

[0025] figure 1 Shows a flow chart of a code type recognition method for a numerically controlled machine tool according to an embodiment of the present invention, including the following steps:

[0026] S102, input the processing code;

[0027] S104: Match the processing code line by line according to the feature points of each CNC system configured by the user, the weight of the feature points, and the preset matching order and matching principle of each CNC system;

[0028] S106: Accumulate the weights of the successfully matched feature points, and if the accumulated weight sum is greater than or equal to a preset threshold, return the type of the numerical control system corresponding to the successfully matched feature points.

[0029] In this embodiment, the processing code is matched line by line according to the preset feature points of each C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com