Annealing treatment method for thinned or scribed gallium nitride base field-effect tube

A gallium nitride base field and annealing treatment technology, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve problems such as device performance degradation, and achieve the effect of improving reliability and stabilizing characteristic parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Functional Overview

[0015] In an embodiment of the present invention, an annealing treatment scheme for GaN-based field effect transistors is provided. In this implementation scheme, slow annealing treatment is performed on GaN-based field effect transistors to improve thinning and scribing. The saturation leakage current of the GaN-based FET can be reduced, the leakage current when the FET is pinched off, and the DC performance and reliability of the GaN-based FET can be improved.

[0016] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

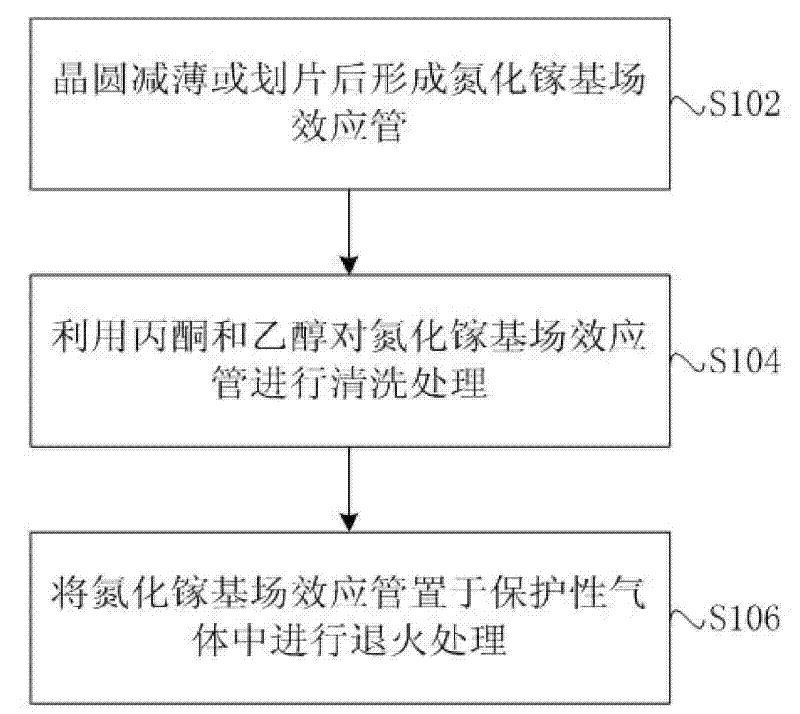

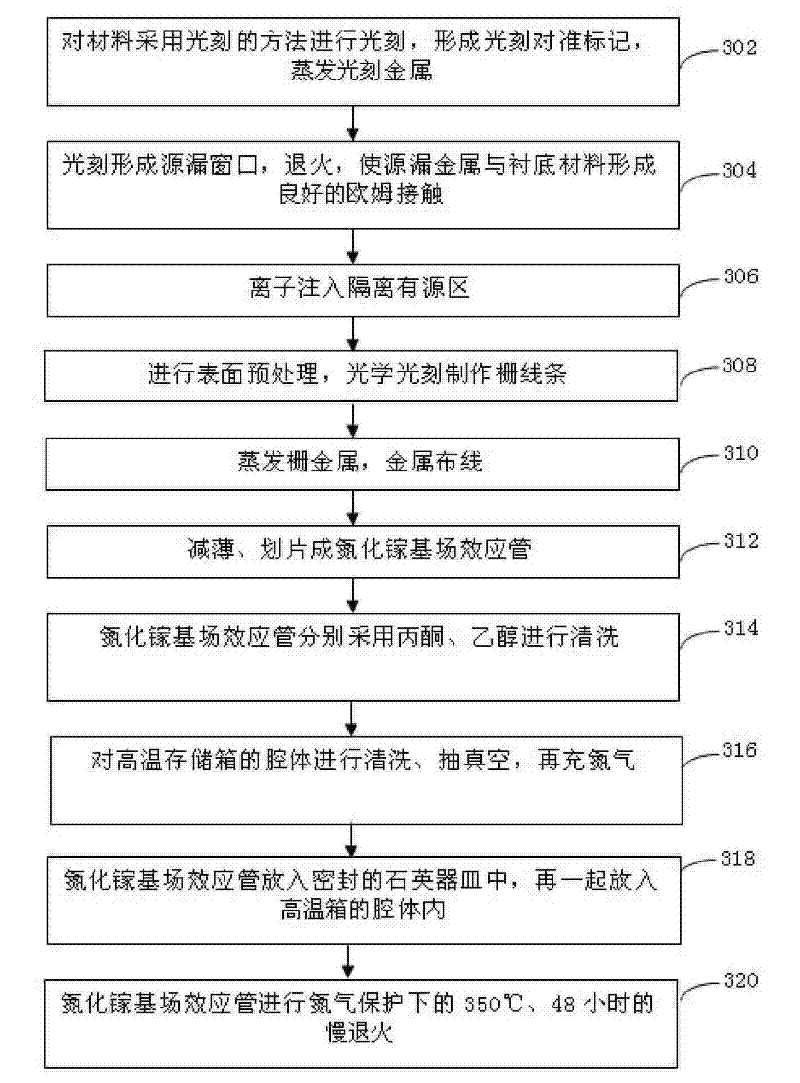

[0017] Such as figure 1 As shown, the present invention provides a method for annealing a GaN-based field effect transistor, comprising:

[0018] In step 102, the wafer is thinned and diced to form a ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com