Manufacturing method for multilayer stacking printed wiring board

A technology for printed circuit boards and production methods, which is applied in the direction of multi-layer circuit manufacturing, etc., can solve the problems of layer deviation scrapping, increase product production costs, complex process flow, etc., and achieve the effect of reducing production costs and improving product qualification rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

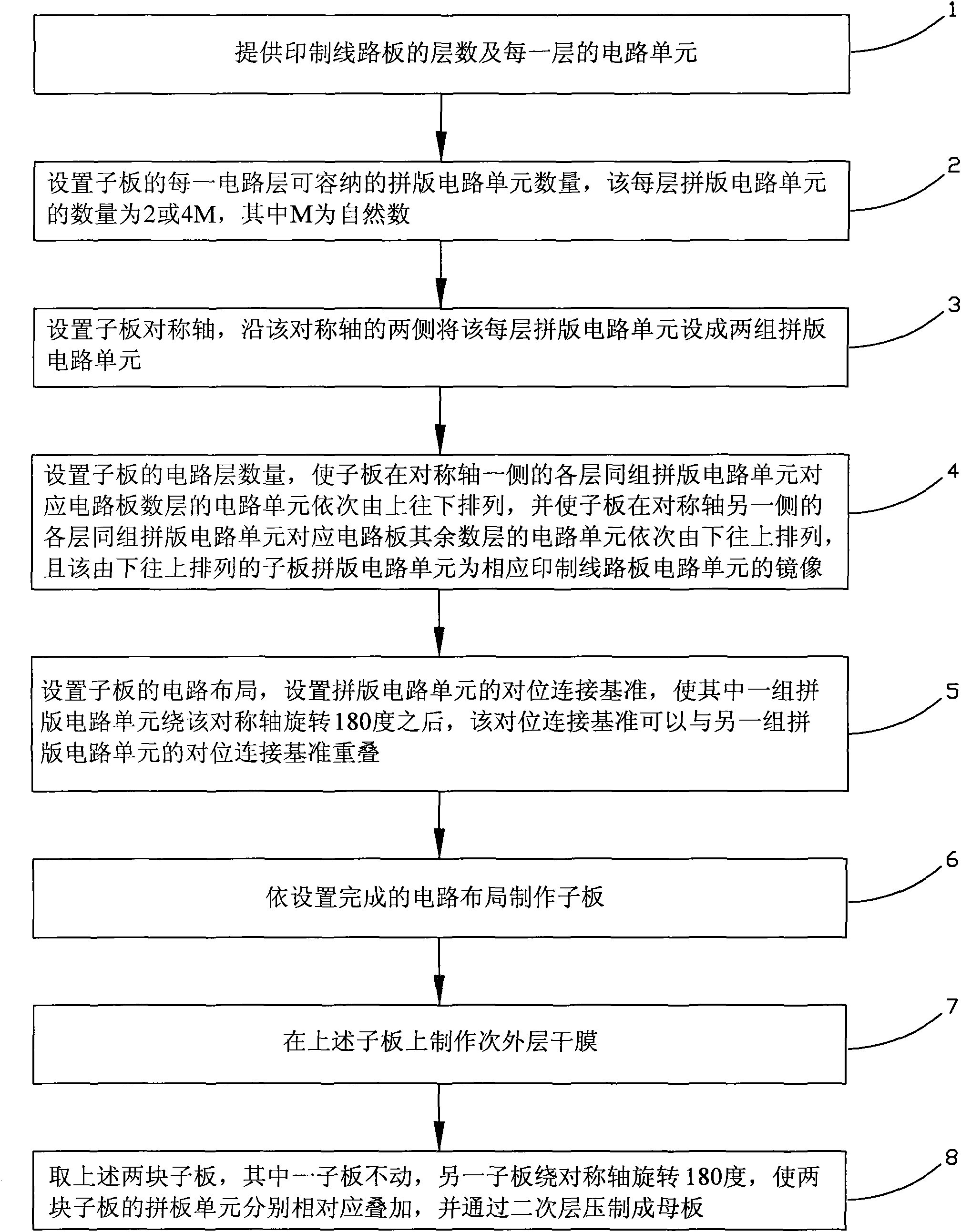

[0027] Such as figure 1 As shown, the manufacturing method of the multilayer superimposed printed circuit board of the present invention comprises the following steps:

[0028] Step 1, provide the number of layers of the printed circuit board and the circuit units of each layer.

[0029] Step 2, setting the number of imposition circuit units that can be accommodated in each circuit layer of the sub-board, the number of imposition circuit units in each layer is 2 or 4M, where M is a natural number.

[0030] Step 3, setting the symmetry axis of the sub-board, and setting the imposition circuit units of each layer into two groups of imposition circuit units along both sides of the symmetry axis.

[0031] Step 4: Set the number of circuit layers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com