Polysilicon purification method and crucible and purification device used for polysilicon purification

A purification method and polysilicon technology, which is applied in the growth of polycrystalline materials, chemical instruments and methods, crystal growth, etc., can solve the problems of low output of a single furnace, high production cost, and high price, so as to avoid secondary pollution and prevent secondary pollution. The effects of secondary pollution and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments. It should be pointed out that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0036] Firstly, the crucible and purification equipment of the embodiment of the present invention will be introduced.

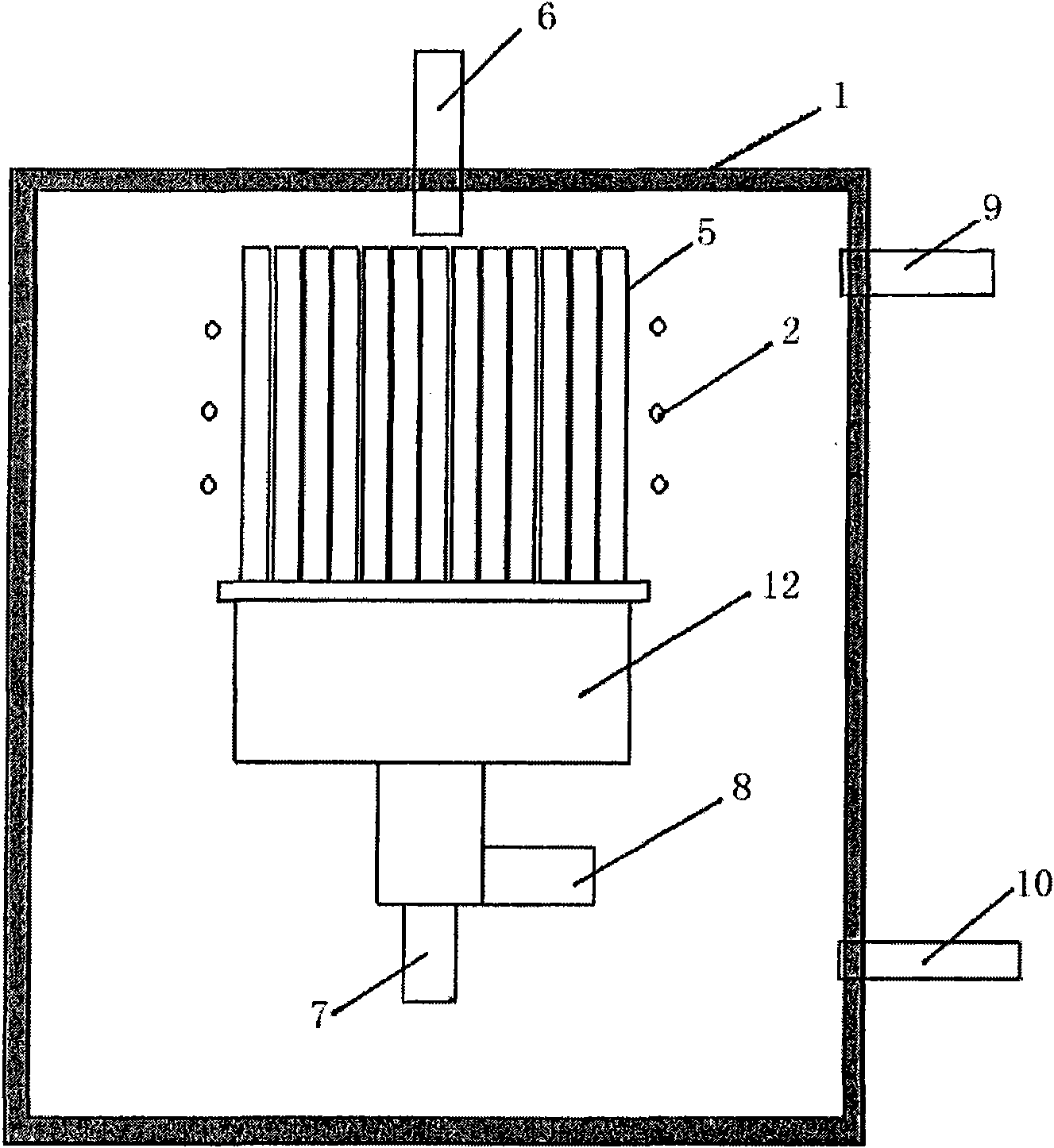

[0037] like figure 1As shown, the crucible for polysilicon purification according to the embodiment of the present invention includes a crucible base 12 at the bottom and a crucible wall 5 arranged on the crucible base, and the inner space surrounded by the crucible wall 5 is used to successively accommodate For the polysilicon raw material to be purified, the polysilicon liquid (molten liquid) or the polysilicon after cooling and solidification, the crucible wall ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap