Method for manufacturing electronic crosslinking foaming material and compositions thereof

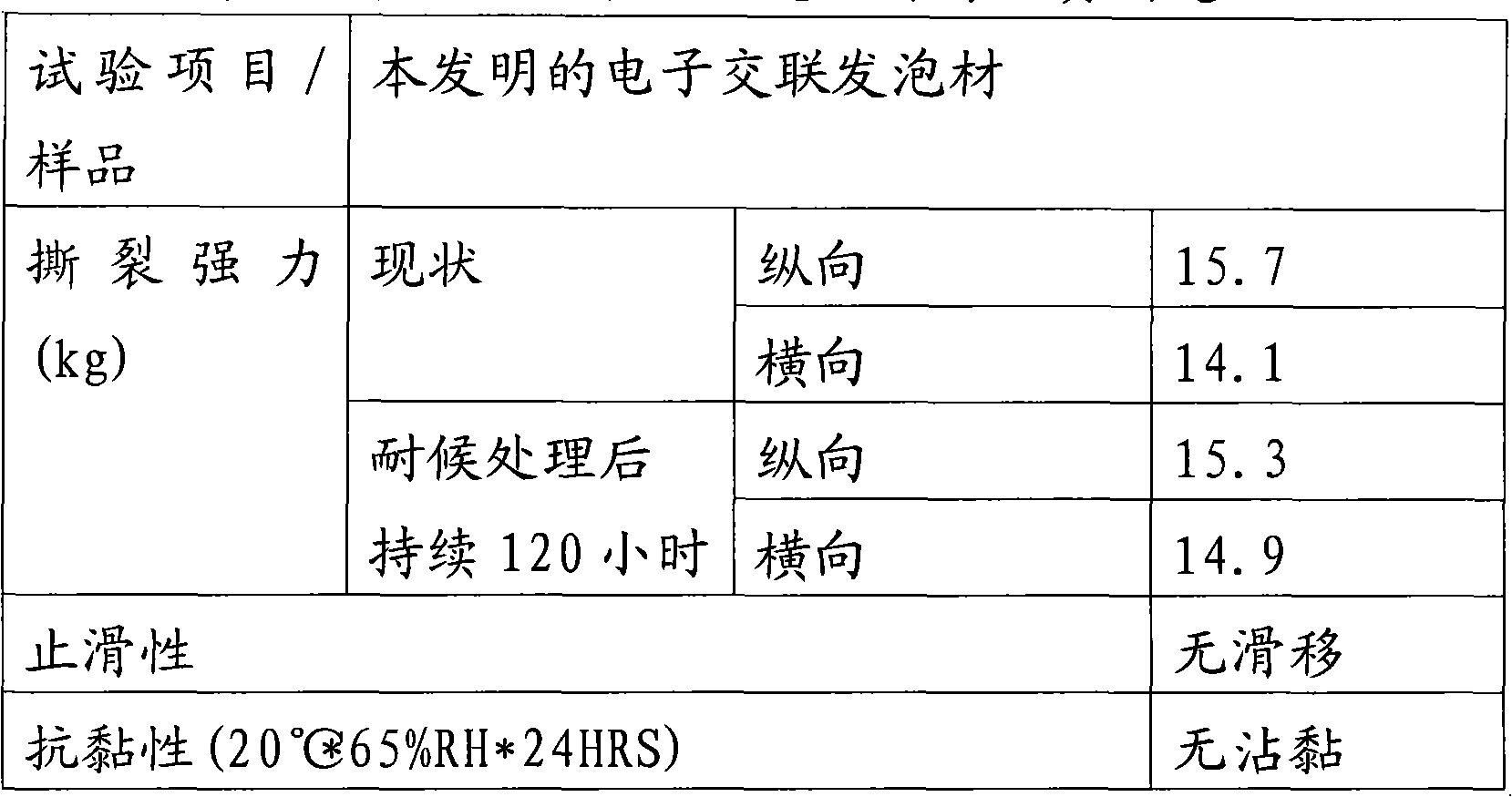

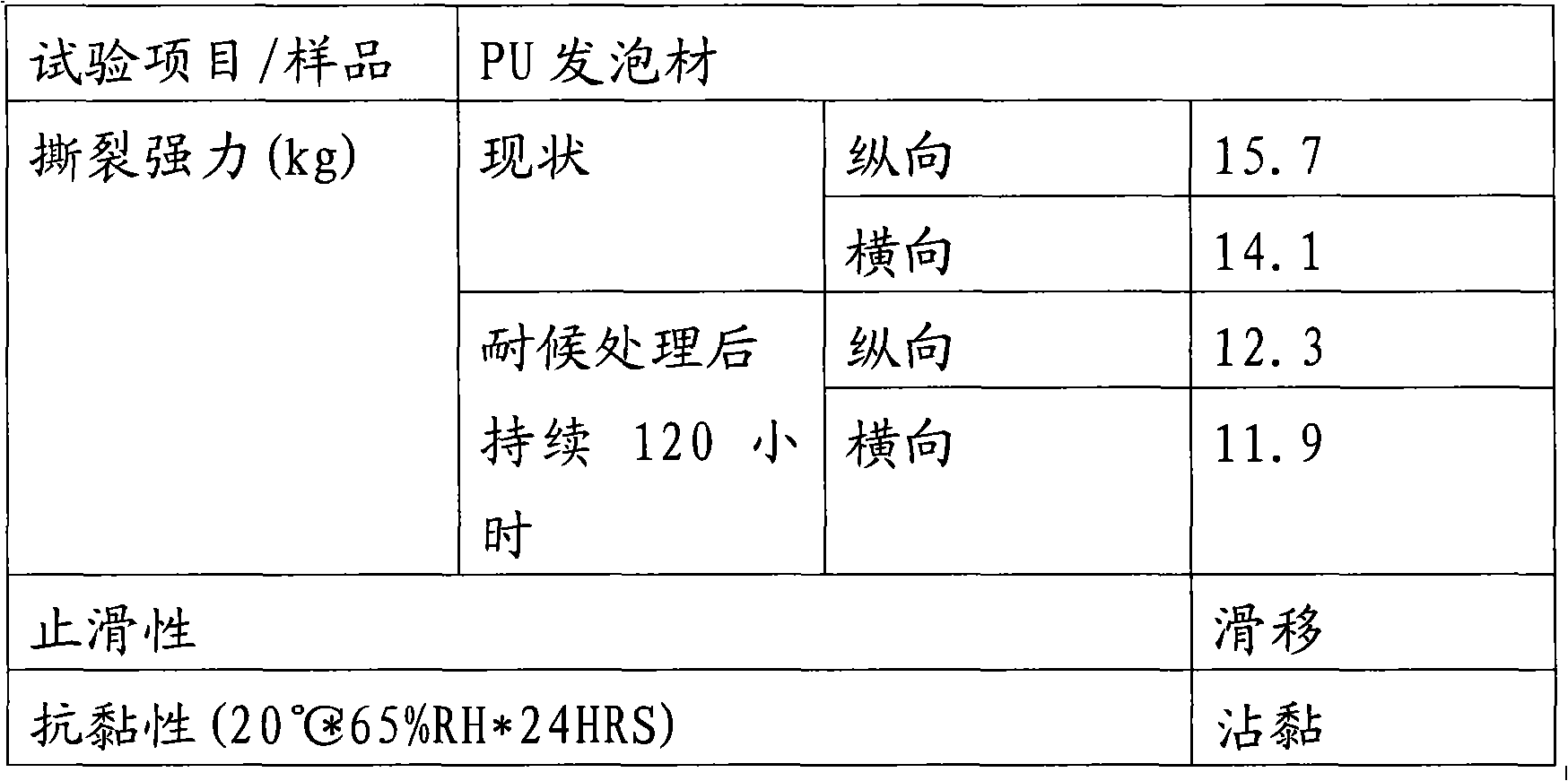

A technology of electronic crosslinking and manufacturing method, which is applied in the fields of aircraft seat cushions and car seat cushions, can solve the problems of crosslinking agent toxicity, spillage, and human respiratory system hazards, and achieve good tear strength, cost reduction, and good safety. The effect of slippery and anti-adhesive properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to enable the examiner to have a further understanding and understanding of the structural features and achieved effects of the present invention, the preferred embodiments and detailed descriptions are as follows:

[0034] The composition of the electronic cross-linked foam material of the present invention comprises: EPDM rubber containing 30 to 80 weight percent; polyolefin plastic containing 0.5 to 12 weight percent; ethylene vinyl acetate containing 1 to 20 weight percent The copolymer; the blowing agent containing 0.5 to 15 weight percent; and the additive containing 0.1 to 11 weight percent.

[0035] Wherein the foaming agent is ethylene-vinyl acetate copolymer (Ethylene / vinylacetate), and the additive is chlorinated polyethylene.

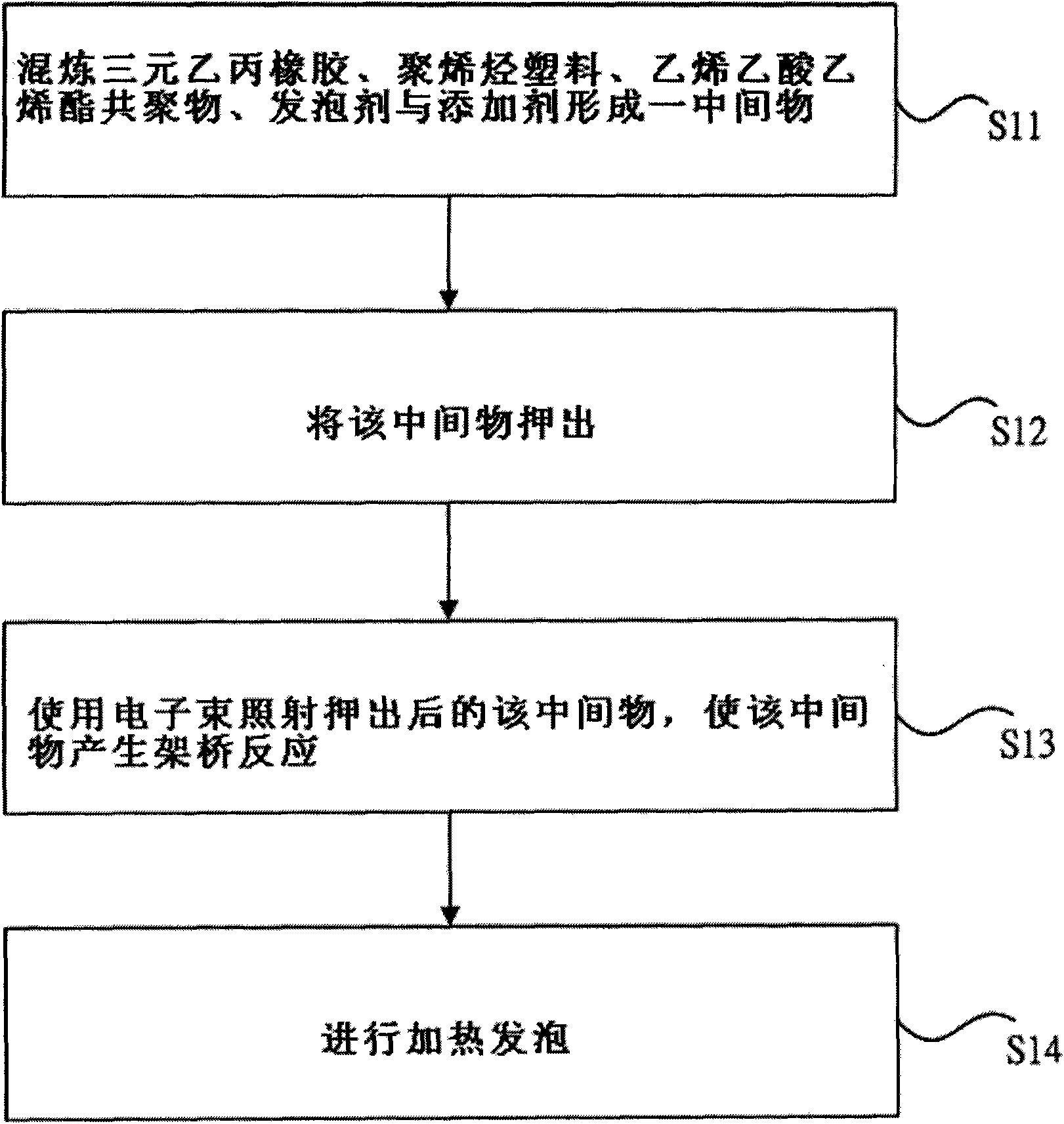

[0036] The manufacture method of electronic cross-linked foam material of the present invention, its step comprises (such as figure 1 shown):

[0037] S11 Mixing EPDM rubber, polyolefin plastic, ethylene vinyl acetate copol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weather resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com