LED lamp with heat dissipation device and manufacturing method thereof

A technology of LED lamps and cooling devices, which is applied in the parts of lighting devices, damage prevention measures of lighting devices, cooling/heating devices of lighting devices, etc., which can solve the problems of harsh outdoor environments, limited use occasions, and different technical solutions problems, to achieve the effect of increased heat dissipation area, flexible installation and use, and efficient heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] specific implementation plan

[0050] The detailed technical contents and embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

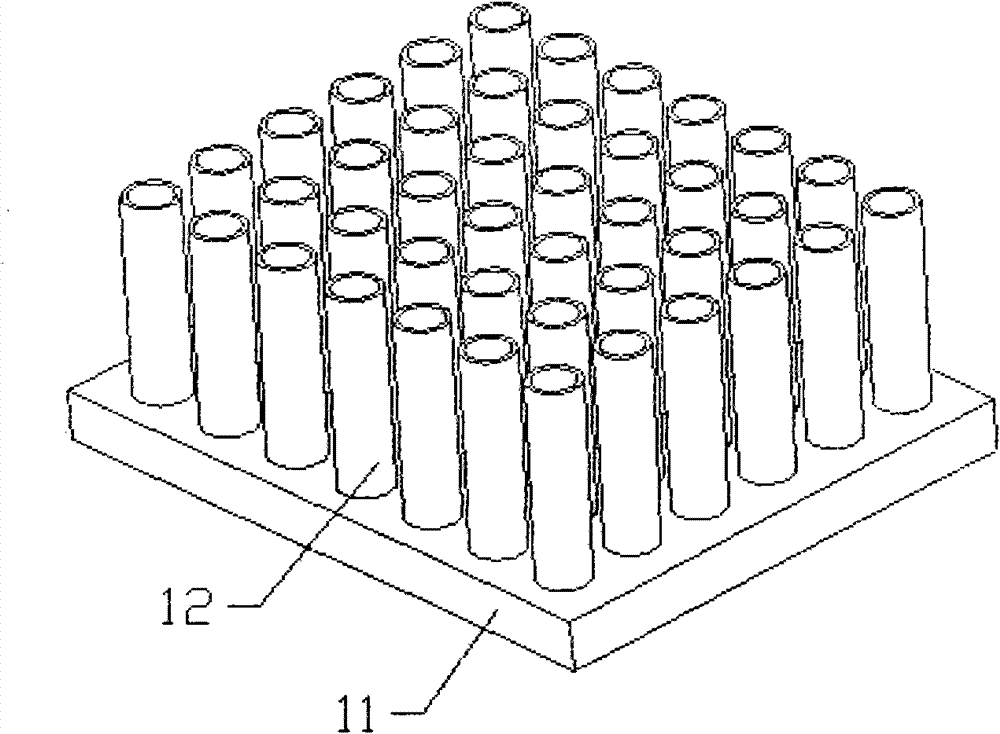

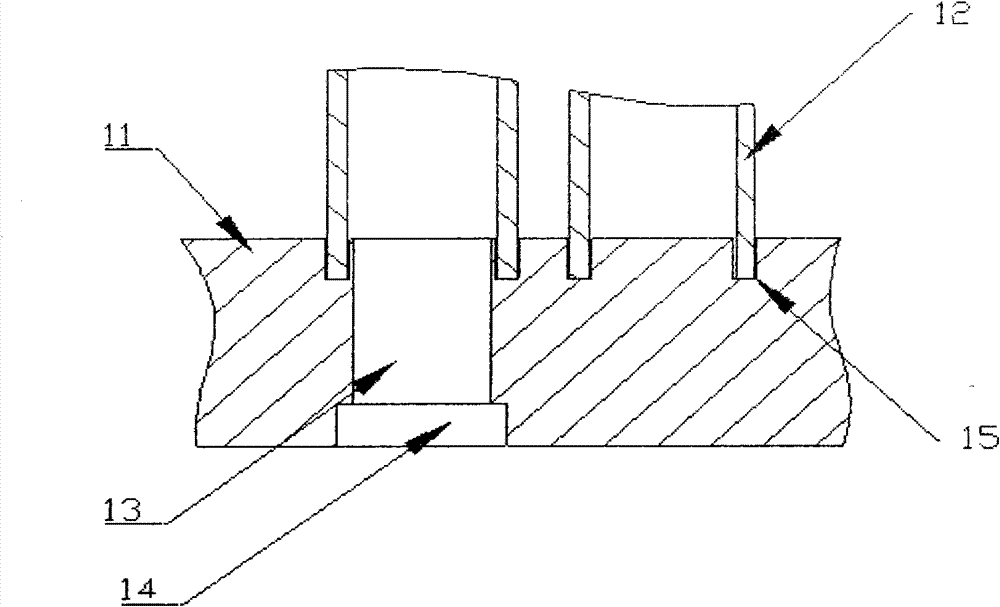

[0051] attached figure 1 It shows a three-dimensional schematic view of Embodiment 1 of the middle piece 1 chimney radiator of the present invention, wherein the cooling handles 12 are all hollow cylinders on the base 11 .

[0052] It should be noted that the heat dissipation rod 12 under the present invention can also be in the shape of a cone or other polygonal geometry, but usually the small end of the cone-shaped heat dissipation rod is arranged upwards and the large end is downwards.

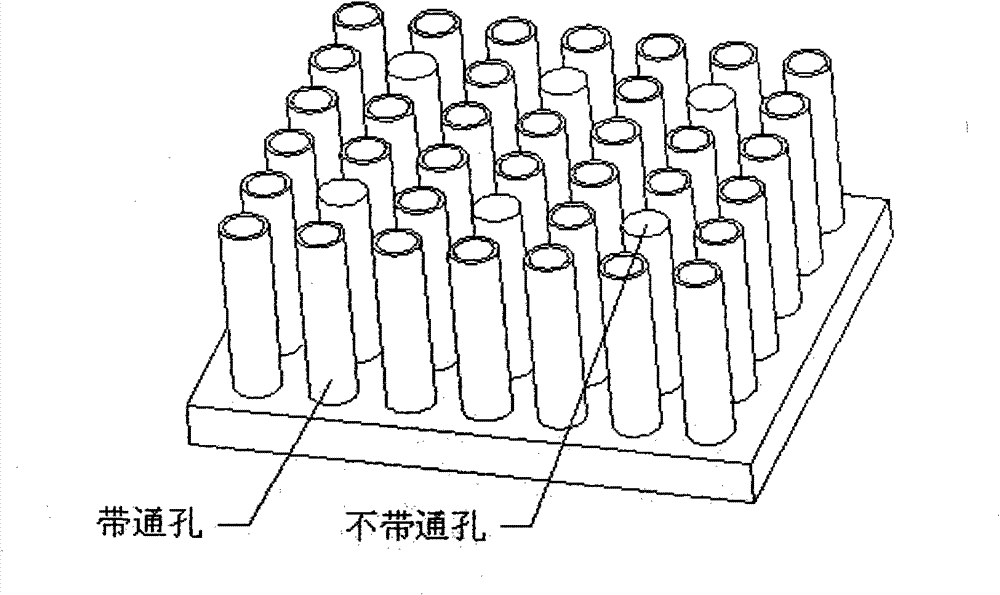

[0053] attached figure 2 It is a three-dimensional schematic diagram of the second embodiment of the middle part 1 of the present invention, wherein a part of the cooling rod 12 is a hollow cylinder, and the other part is solid, and they are also arranged on the base 11. The hollow cooling ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com