Exhaust recovery device of deaerator

An exhaust gas recovery and deaerator technology, applied in liquid degassing, chemical instruments and methods, separation methods, etc., can solve the problems of unutilized steam heat, increased atmospheric emissions, environmental thermal pollution, etc., and achieve energy-saving effects The effect of obvious, protecting the environment and eliminating air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

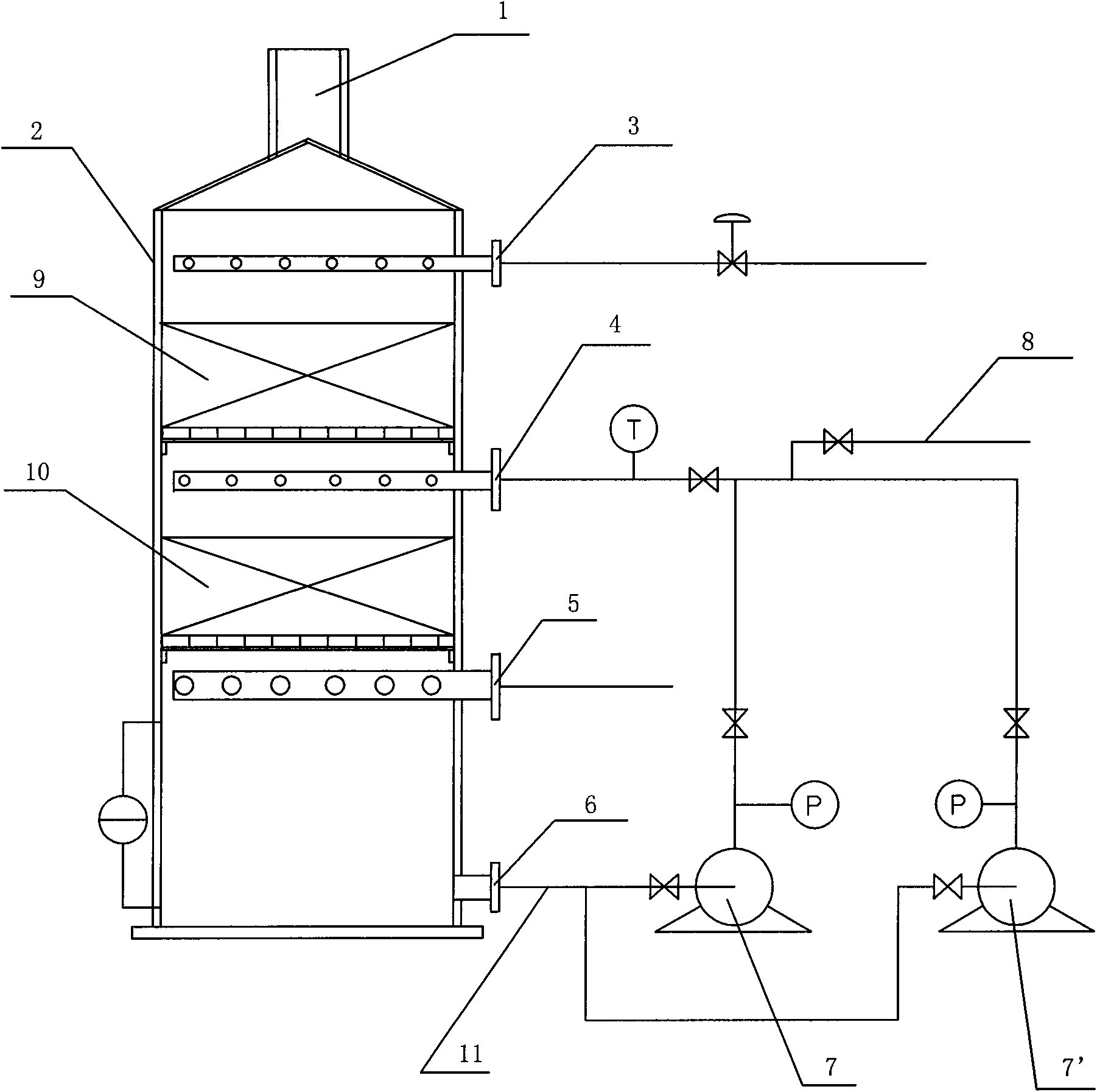

[0010] Such as figure 1 As shown, the present invention includes a packed tower shell 2, the filler in the packed tower shell 2 is divided into an upper packing layer 9 and a lower packing layer 10, the top of the packed tower shell 2 is provided with an exhaust port 1, and the packed tower shell 2 The upper part is provided with a cold water inlet 3, the lower part of the packed tower shell 2 is provided with a steam inlet 5 and a hot water outlet 6 in sequence, and the circulating hot water inlet 4 is arranged on the packed tower shell 2 between the upper packing layer 9 and the lower packing layer 10 , one end of the water outlet pipe 11 communicates with the hot water outlet 6, the other end of the water outlet pipe 11 communicates with the inlets of the two water pumps 7, 7' respectively, the outlets of the two water pumps 7, 7' communicate with the circulating hot water inlet 4, and the two water pumps The pipeline between 7 and 7' communicates with the water inlet pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com