Automatic vesicle gashing device

A capsulation, automatic technology, applied in ophthalmic surgery and other directions, can solve problems such as failure of surgery, lack of excellence, and inability to obtain a circle, and achieve the effect of reducing the technical level of surgery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

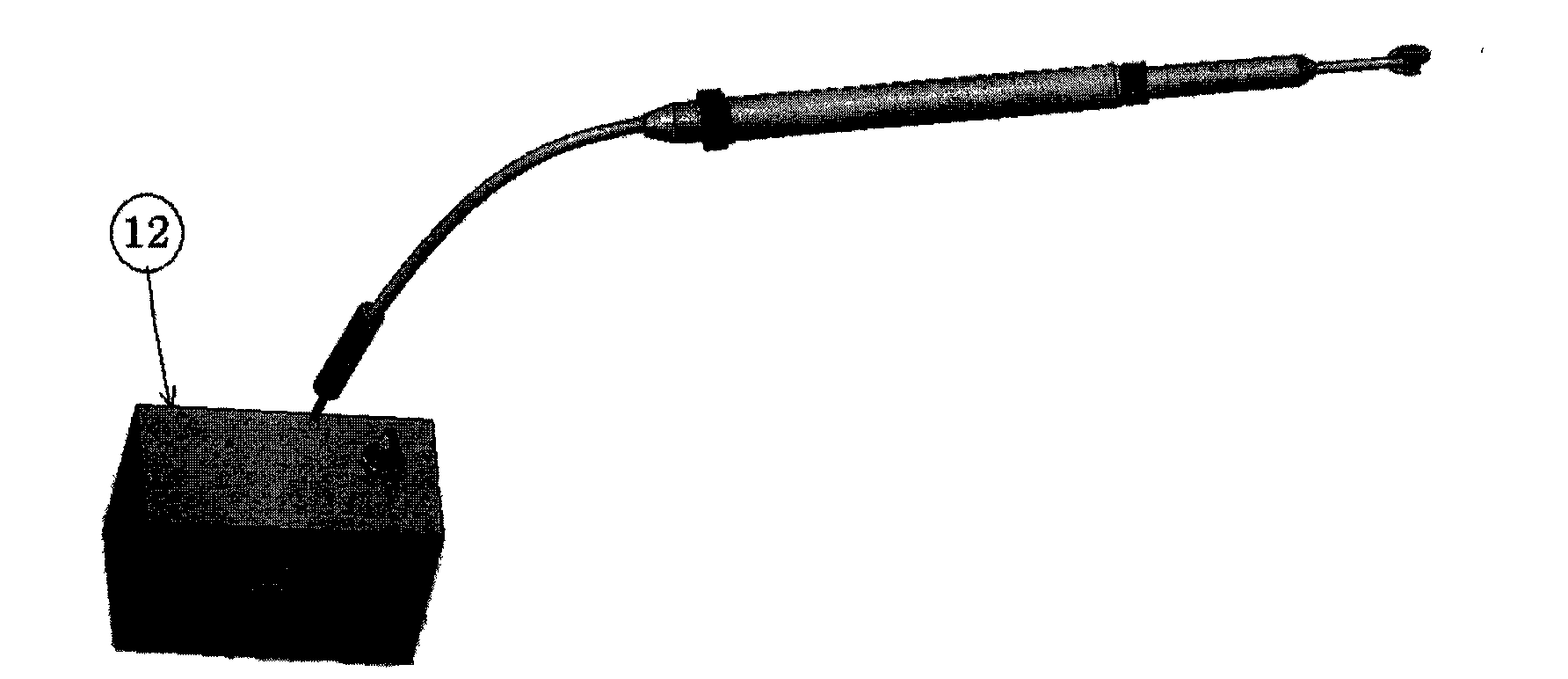

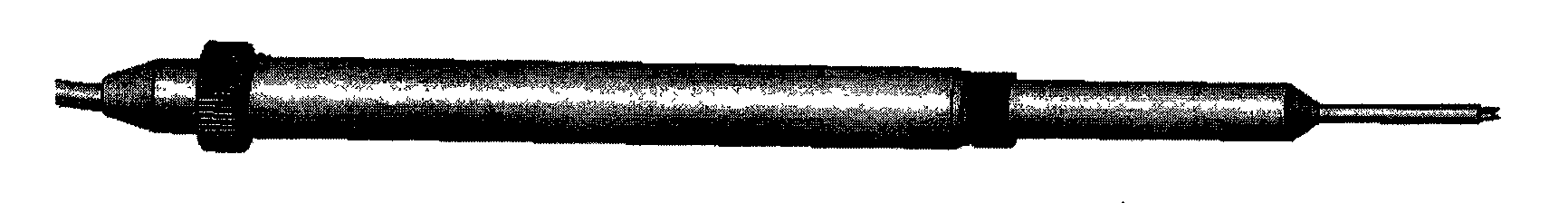

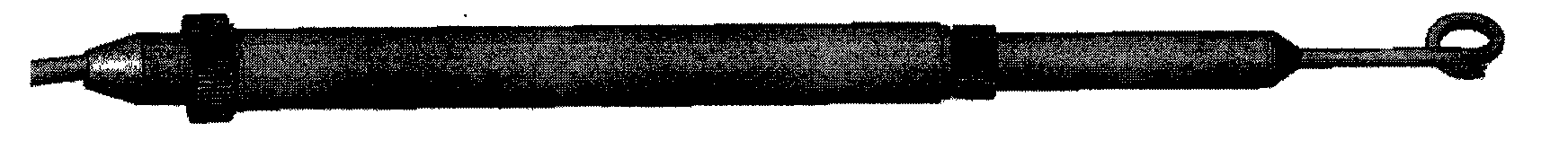

[0017] Fix the bag cutter, install the handle, and retreat the bag cutter to the innermost side, leaving only the knife head outside the tube, such as ( figure 2 Exterior, Figure 4 section). Make a corneal incision, enter the selected position from the incision, the knife head penetrates the capsule, the control box or the hand rotates the inner core of the transmission flexible shaft, and drives it into the handle, the push rod pushes the capsule knife out of the tube, and the capsule knife returns to its original shape ( image 3 Exterior, Figure 5 Cross-section), the knife head draws or cuts the capsule membrane according to a circular arc, forming a smooth circle. Reverse rotation, the push rod pulls back the pouch cutter, and the head of the pouch cutter is transformed into a straight rod and returned to the pipe. Withdraw from the corneal incision and proceed to the next step of the surgery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com