Gas-oil-water separation system

A separation system, gas-oil-water technology, applied in separation methods, liquid separation, dispersed particle separation, etc., can solve the problem that oil and water cannot be separated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

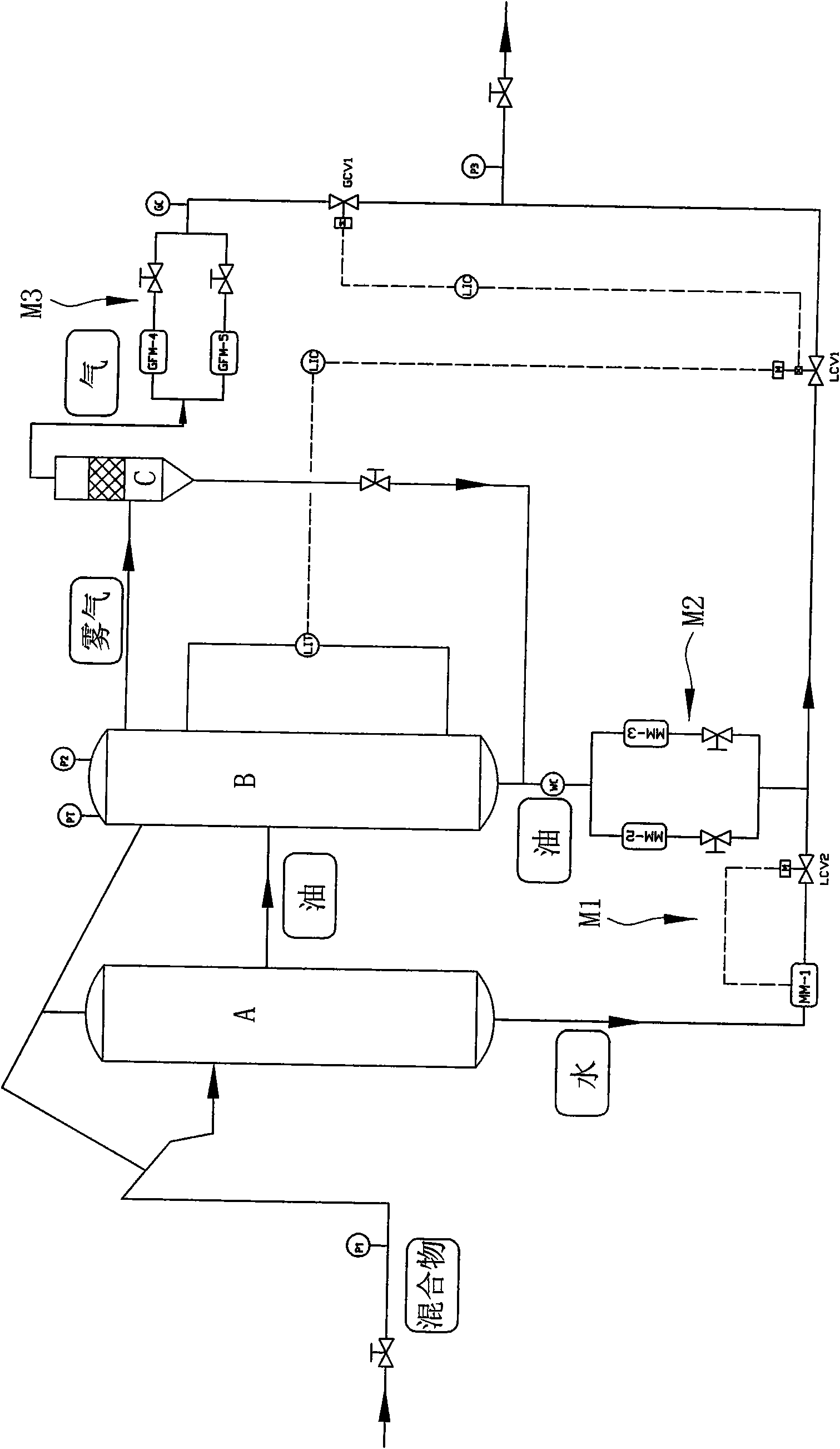

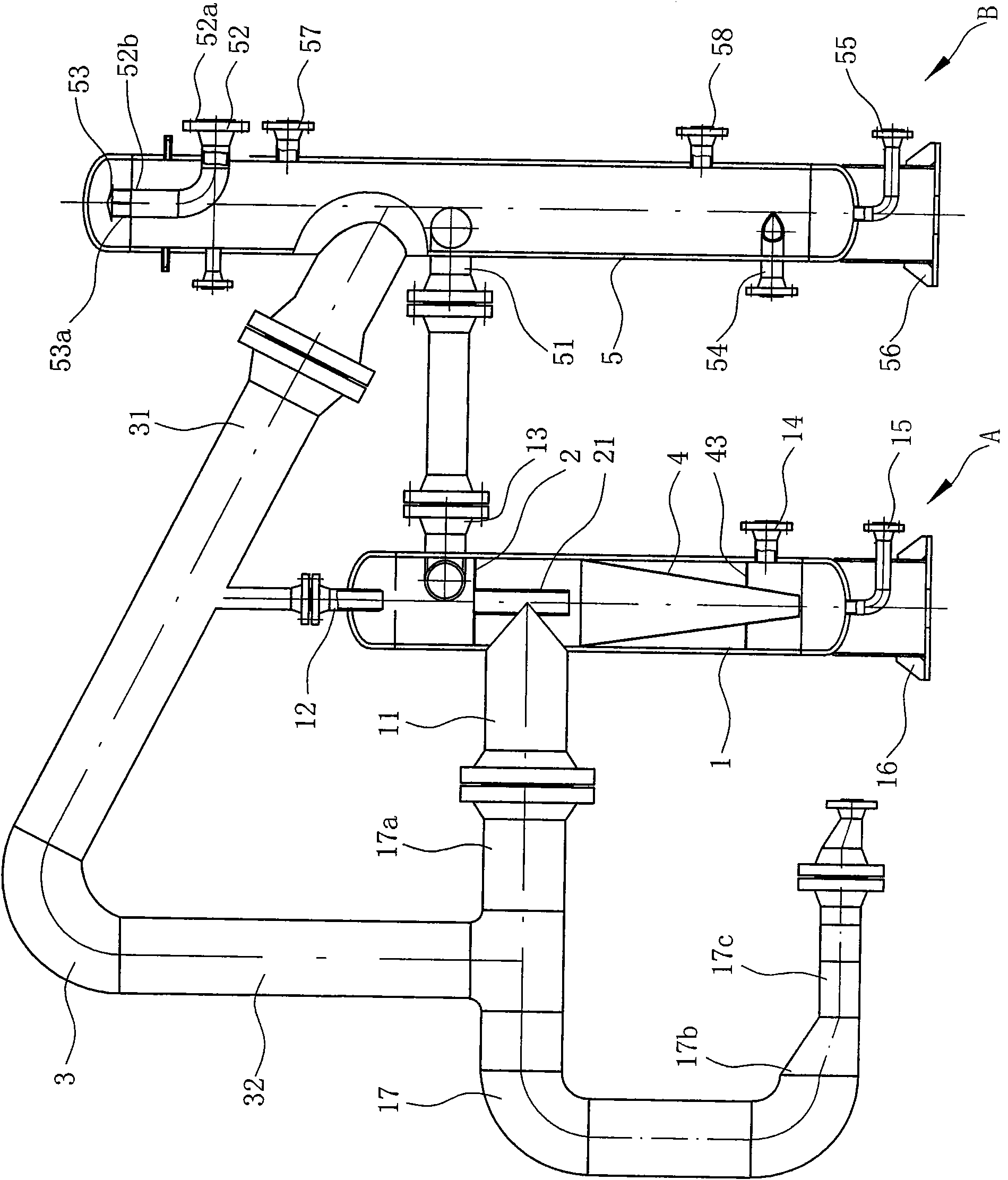

[0042] Such as Figure 1 to Figure 6 As shown, the gas-oil-water separation system includes a cyclone-type gas-oil-water separator A, a cyclone-type gas-oil separator B and a mist catcher C.

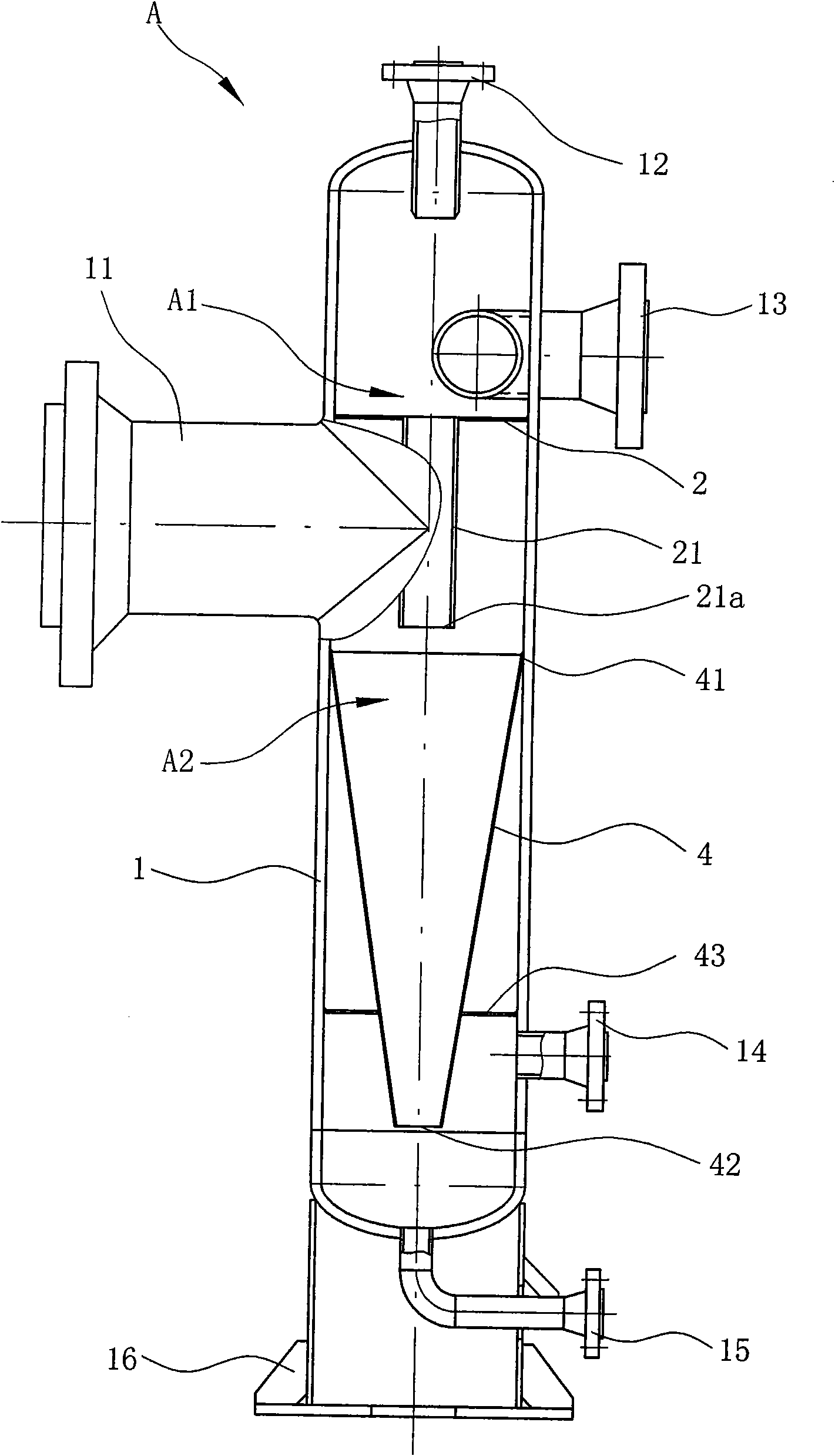

[0043] Among them, such as figure 2 , image 3 As shown, the cyclone-type gas-oil-water separator A includes a first columnar body 1, and the wall of the first columnar body 1 is sequentially provided with holes communicating with the interior of the first columnar body 1 from the top to the bottom. The first air outlet pipe 12, the first oil outlet pipe 13, the first input pipe 11, and the water outlet pipe 14, the first input pipe 11 is tangent to the cylinder wall of the first cylindrical cylinder body 1, and is on the wall of the first cylindrical cylinder body 1 There is a sewage outlet 15 at the bottom, and a first skirt support 16 is also prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com