Branch crushing machine

A technology of a chipping machine and a machine head, which is applied in the field of chipping machines, can solve the problems of increasing the packaging size, unfavorable use of the motor, and no cooling mechanism, and achieves the effect of reducing the length size, reducing the packaging size, and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

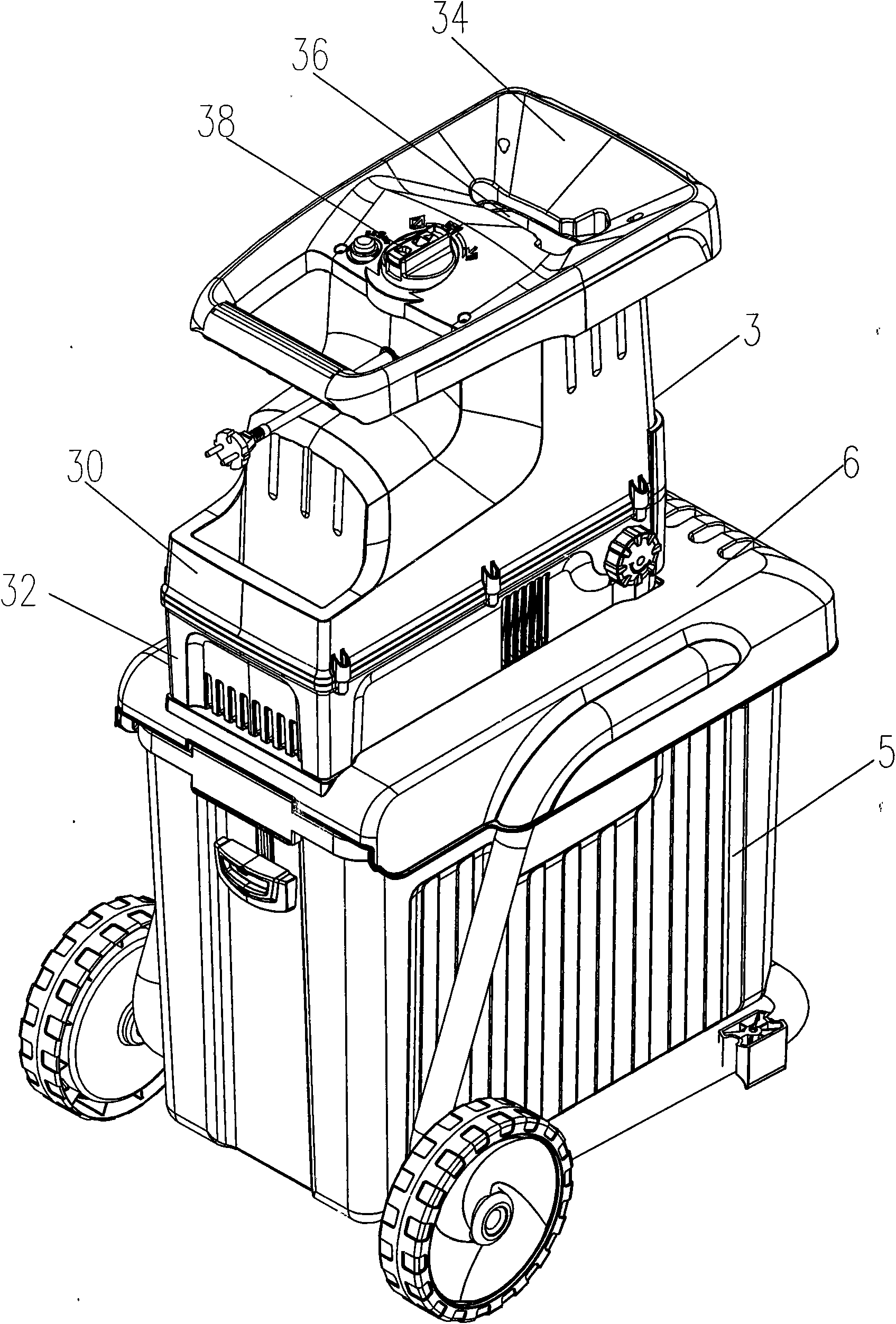

[0019] Reference figure 1 , Shown is a garden shredder corresponding to the best embodiment of the present invention, which mainly includes a frame 1 with rollers. The frame 1 has a table 6 and a machine head above the table 6 3, and there is a material box 5 below it.

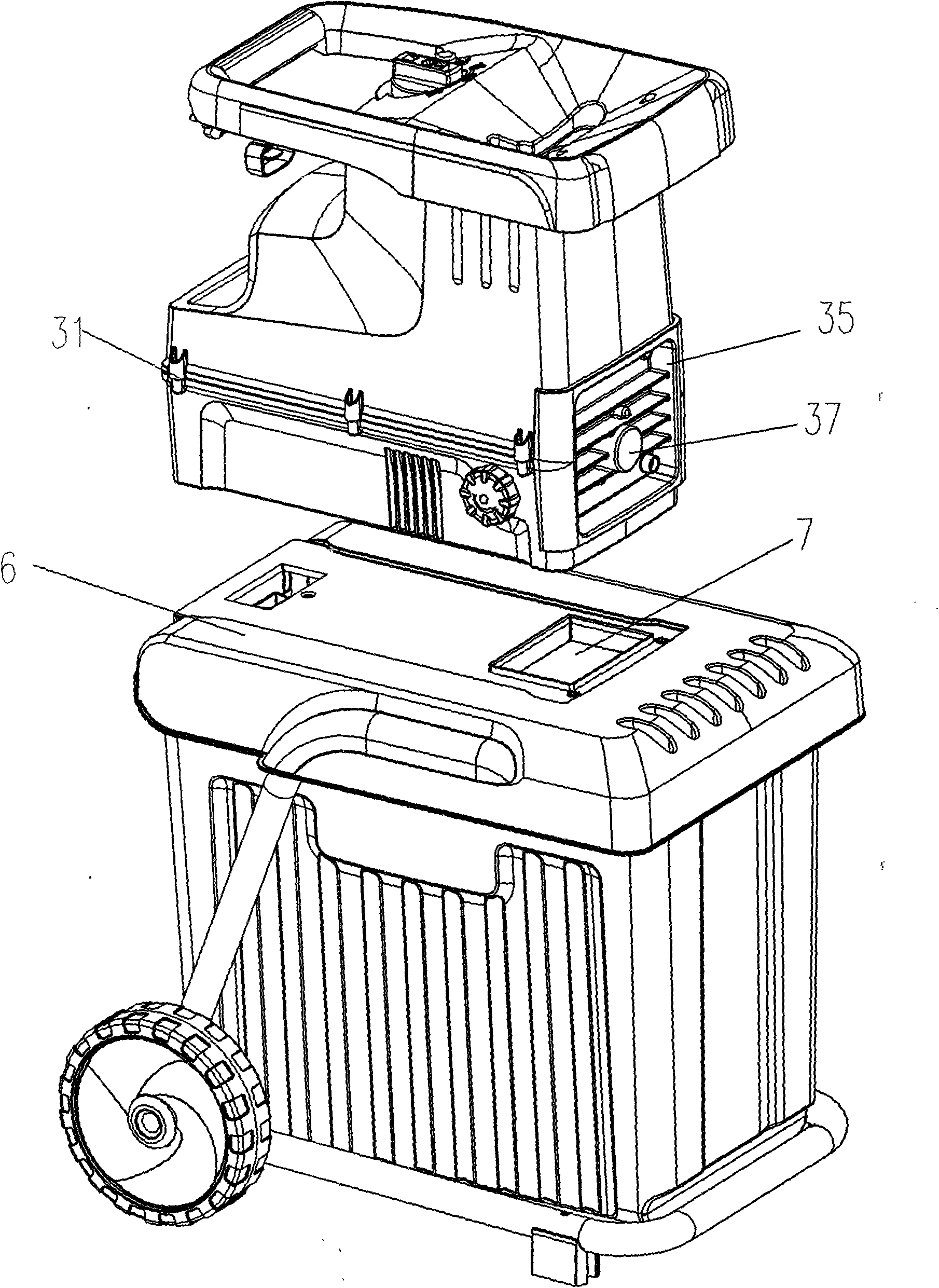

[0020] Further reference figure 2 with image 3 The head 3 includes upper and lower housings 30 and 32, which are fixedly connected by screws 31. A panel 34 is integrally formed on the top of the upper casing 30. The panel 34 is provided with a feed port 36 and a switch device 38 located beside the feed port 34. In addition, the machine head 3 is also provided with an end cover 35 which is fastened to the upper and lower housings 30 and 32 in the existing manner. At the same time, the end cover 35 is also provided with a supporting and positioning member 37.

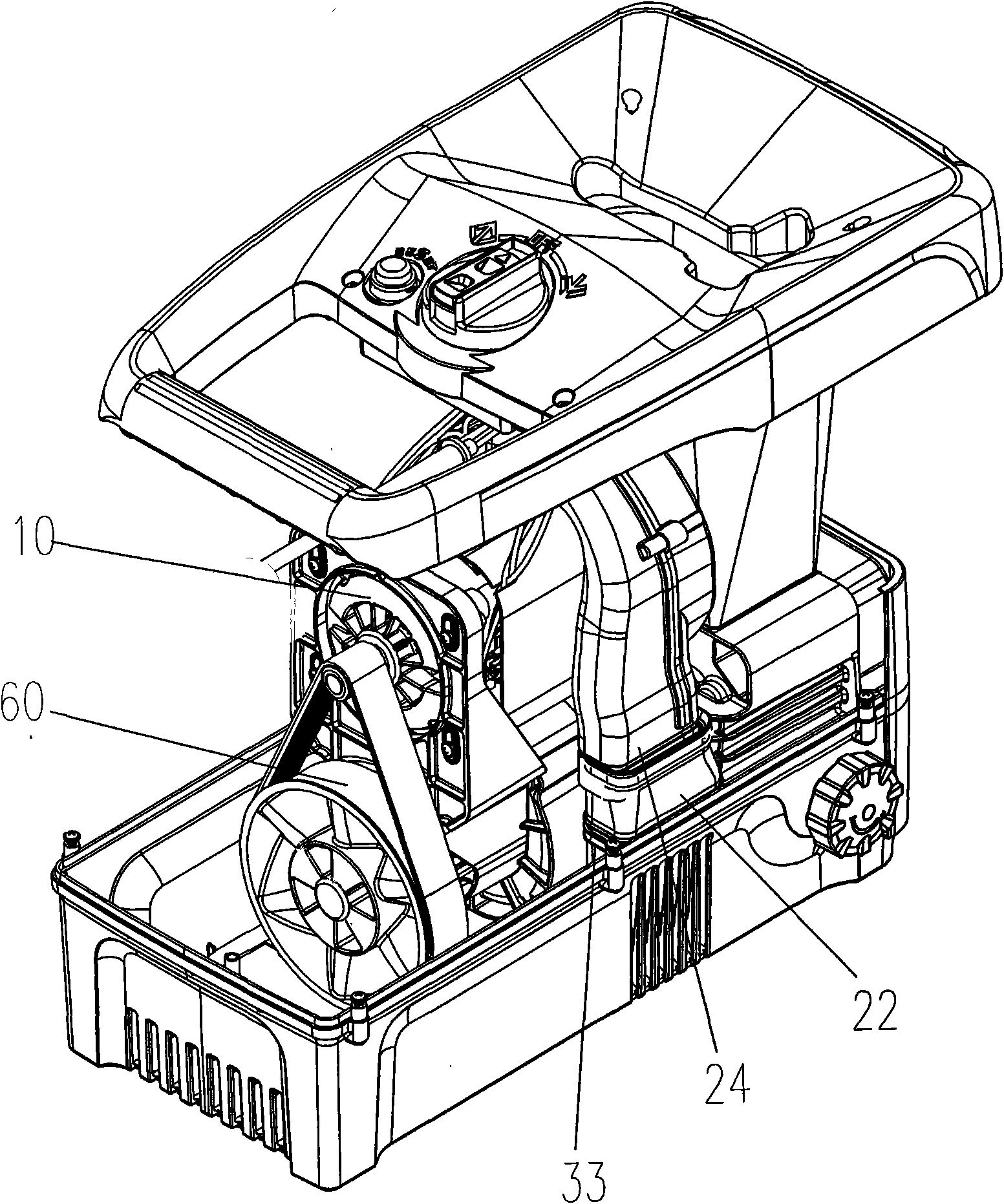

[0021] Inside the upper and lower housings 30 and 32, there are mainly installed a motor assembly 10, a hob assembly 50 driven by the motor assembly 10, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com