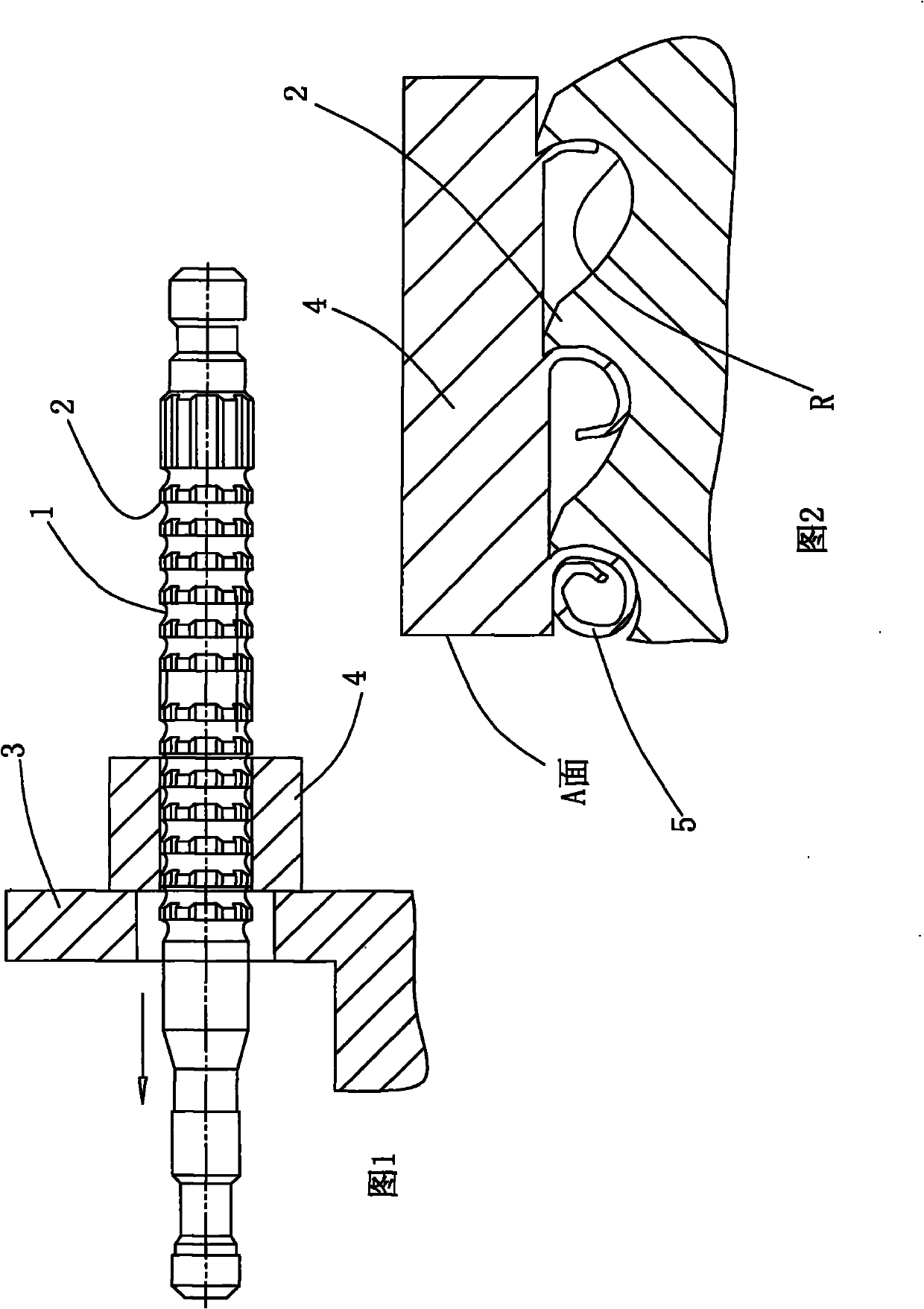

Special circular broach numerical control cutter-sharpening machine tool

A technology of special-purpose machine tools and CNC lathes, which is applied in the field of machine tools, can solve problems such as unstable product broaching quality, large bending of broaches, inconsistent tooth pitch of broaches, etc., so as to expand the use function and facilitate promotion and production convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0018] The specific implementation, non-limiting examples are as follows:

Embodiment

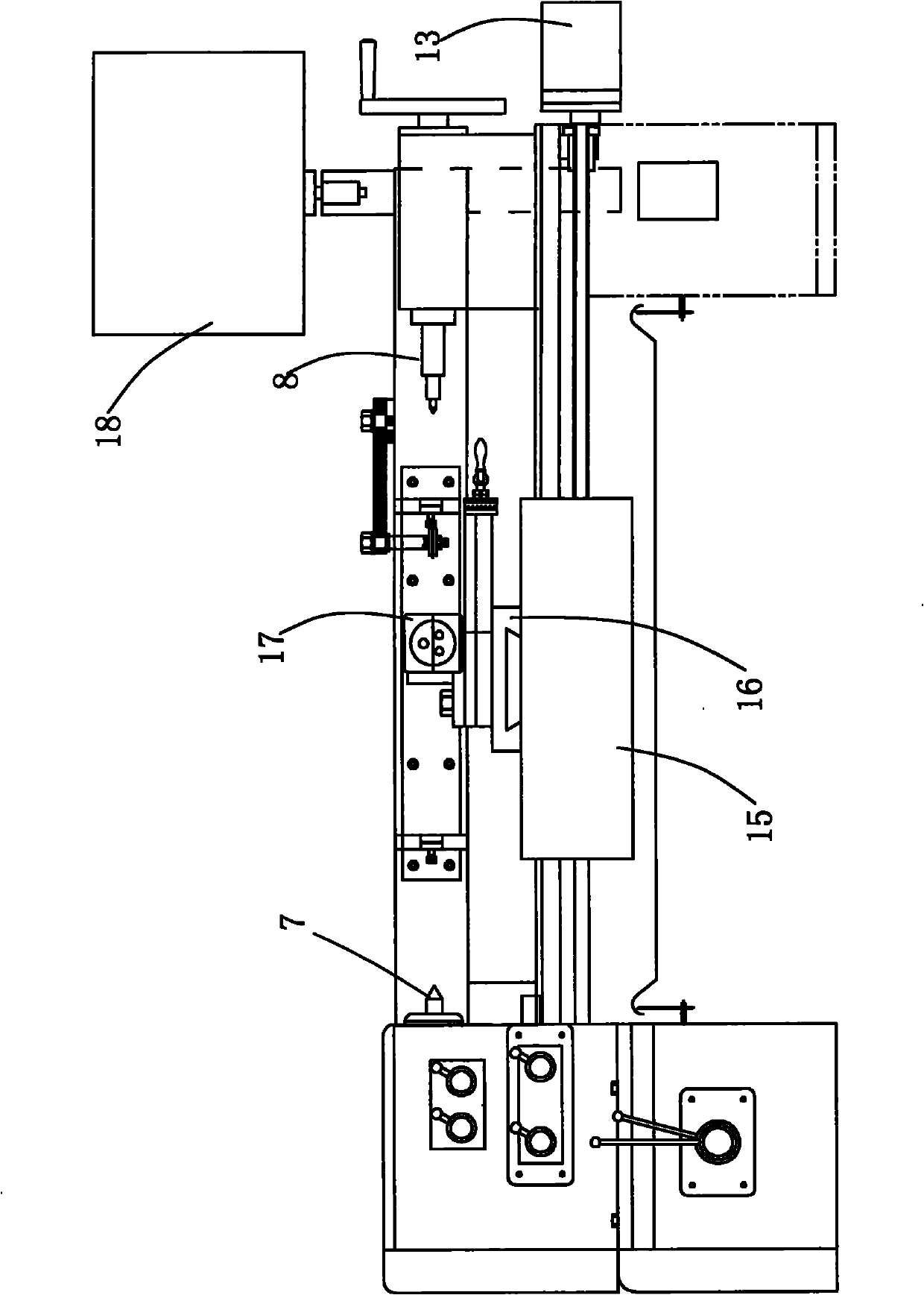

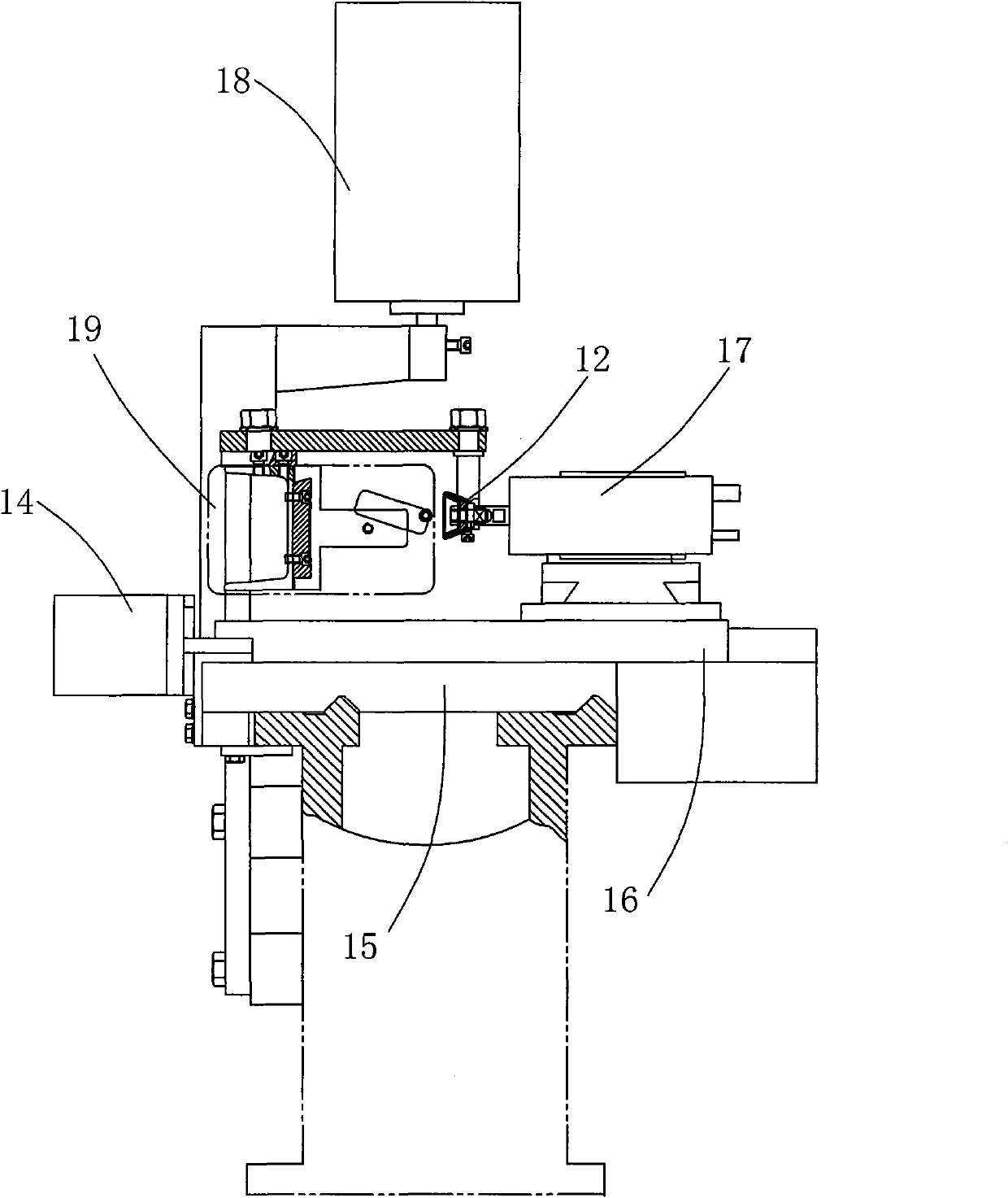

[0019] Example: Combined image 3 , 7 , the special machine tool for CNC sharpening of round broaches in this embodiment is improved from existing CNC lathes. The center holes on the end faces of the two ends of the broach 6 are inserted into the output shaft top 7 of the head of the lathe and the elasticity of the tail of the lathe respectively. On the top 8, the axes of the output shaft top 7 and the elastic top 8 coincide. On the flange 9 of the output shaft top, an extension rod 10 parallel to the output shaft top is fixed, and the end of the extension rod is fixed with a clamp 11. Hold the broach 6 and drive the broach to rotate with the flange.

[0020] combine Figure 4 , because the broach has a small diameter and a long length, in order to ensure its rigidity and avoid radial bending during sharpening, 3 to 5 lathes are distributed along the axis of the broach on one side of the lathe (opposite to the grinding wheel 12) on the bed The broach support frame 19 forms ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com