Special airbag for carrying heavy goods

A technology of airbags and heavy objects, which is applied in the direction of lifting devices, etc., can solve the problems of low lifting height, twisted airbags, high lifting height, etc., and achieve the effects of increased working pressure, reduced rolling moment, and reduced rolling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

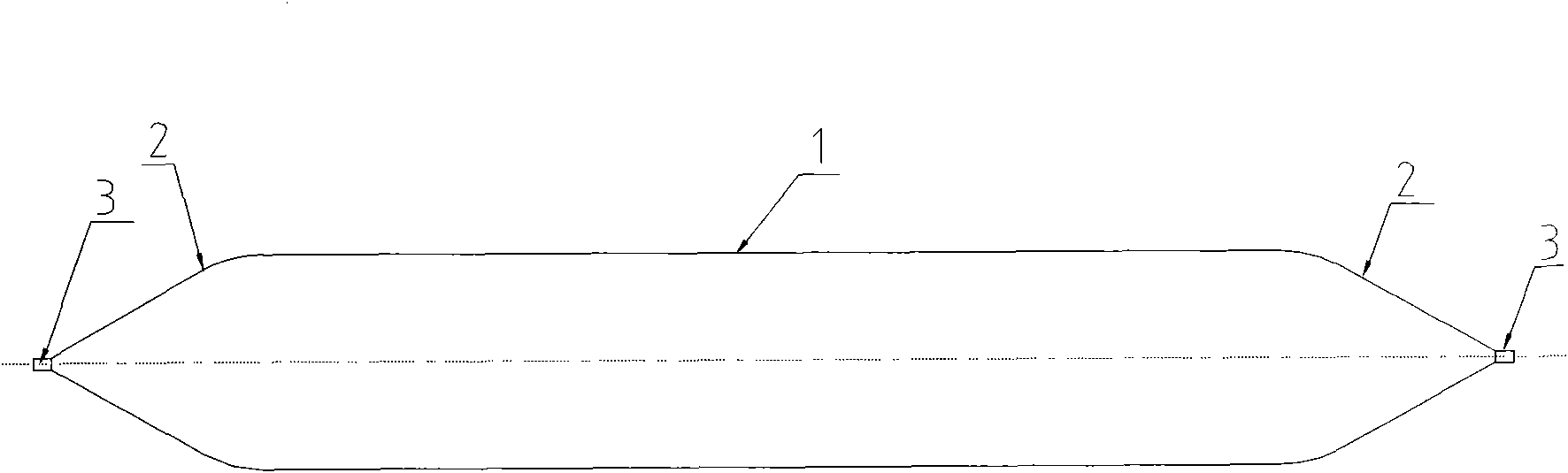

[0026] Embodiment 2, as shown in the figure, is used for carrying an airbag in a caisson, and is composed of an airbag body 1 , an airbag head 2 and two airbag nozzles 3 distributed at both ends of the airbag head 2 . The height of the caisson is 23m, its base is 17m long, 11m wide, and weighs 2100t. Seven special airbags with a diameter of 0.4m and a length of 11m are used to carry the upper semi-submerged barge. The airbag body 1 contains a skeleton layer of three layers of steel cords, the outer glue thickness of the airbag body is 3 mm, and the diameter of the airbag mouth 3 is 15 mm. When moving the caisson, the lifting height is 0.16m, the working pressure is 0.8MPa, and the traction force of the caisson walking is about 2.2% of its weight. The caisson walks almost without swinging.

[0027] If adopt eight diameters to be the air bag of 1m to carry this caisson, the hoisting height is 0.4m, the traction force of caisson walking is more than 3% of its weight, its stabili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com